- | 9:00 am

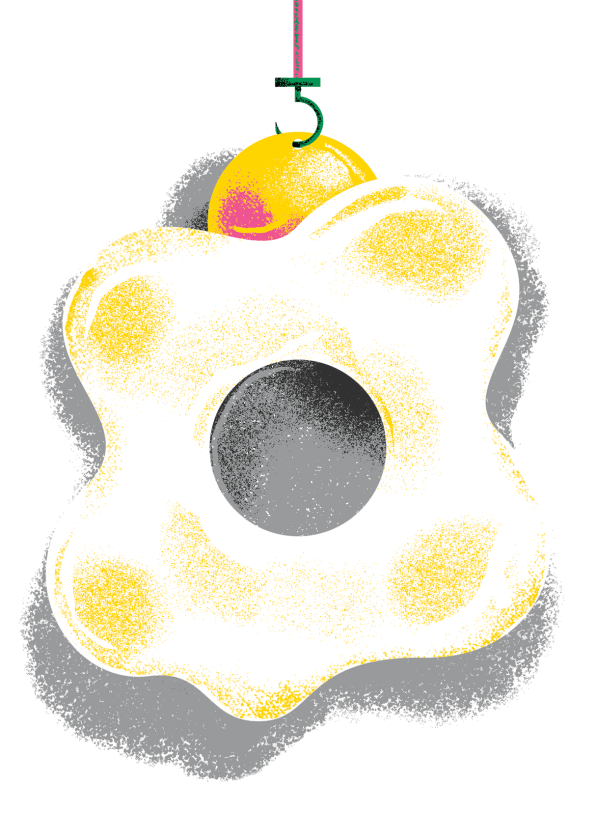

These egg whites were made in a lab—but they’re identical to the real thing

Onego Bio’s animal-free egg whites are a winner in Fast Company’s 2023 World Changing Ideas Awards.

Onego Bio is one of the winners of Fast Company’s 2023 World Changing Ideas Awards. Explore the full list of projects we’re honoring for making the world more equitable, accessible, and sustainable.

Egg whites can expand six to eight times in volume when whisked or whipped, and they help to bind ingredients together. They make our foods fluffy, foamy, or even sticky. Those functionalities are a product of specific proteins—the most abundant of which is called ovalbumin—which can’t easily be replicated with plant-based alternatives.

Ovalbumin is “one of nature’s wonders,” says Maija Itkonen, CEO of biotech company Onego Bio. But eggs are also, she notes, rife with environmental and ethical issues: Cage-free hens account for just 34% of all egg-laying flocks, and though responsible for fewer emissions than proteins like beef, 86% of eggs are still produced in carbon-intense industrial-farm settings, totaling some 200-plus-million metric tons of CO2 each year.

Onego Bio, which launched in February 2022 after it spun out from the VTT Technical Research Centre of Finland, uses precision fermentation to make an animal-free egg white called “bioalbumen.” It currently comes as a powder and can easily fit into existing production systems; egg white powders in general are common for use in everything from confectionaries to protein supplements. This innovation is the winner of Fast Company’s World Changing Ideas Awards in the Food category.

Onego Bio says its chicken-free egg whites have an environmental impact that’s up to 90% lower than egg whites from hens. Because bioalbumen is genetically identical to ovalbumin, it’s not an egg white alternative: It’s the real thing. That means it has all the same properties crucial for foods—and other products. Egg white proteins are used in cosmetics to tighten skin, in the fining of wine, and in pharmaceuticals.

The company is partnering with Perfect Day, a precision fermentation leader that makes milk proteins sans cows, to help scale up and commercialize bioalbumen. Plans for a factory with an output equivalent to 2 million chickens are in the works.