- | 9:00 am

Solving the concrete paradox: How rebuilding Turkey could pave the way to a more sustainable future

By using a common form of clay as a supplement in the production of cement, manufacturers might reduce their carbon emissions by as much as 75 percent.

In the early morning hours of February 6, 2023, Turkey experienced its most powerful earthquake in more than 80 years. The quake, 7.8 on the Richter scale, together with strong aftershocks, killed more than 50,000 people, left one and a half million people homeless, and destroyed more than 210,000 buildings. It created enough rubble to cover about 40 square miles (twice the size of Manhattan) a yard deep in debris. A UN estimate puts the damage to Turkey’s built environment at more than $100 billion. More than a hundred countries, the UN, the World Bank, and other global and local charities are stepping up with billions of dollars worth of assistance and loans.

The Turkish government has pledged to build 319,000 new houses in the next year, promising greater oversight to prevent corrupt construction practices that resulted in substandard concrete buildings and contributed to the magnitude of the recent destruction.

But Turkey’s urgent mission to respond to a tragic disaster also illustrates the global bind we find ourselves in at this particular moment in our evolution on our planet: The very same material we rely on to both protect us from environmental hazards and to rebuild after them—concrete—is the world’s second biggest source of carbon emissions, fueling a climate crisis that is generating more extreme weather, leading to more disasters and destruction. Call it the concrete paradox.

Whether you lean towards optimism or skepticism regarding an Erdogan-led government’s promises to root out corruption, this much is true: As Turkey rebuilds, it can rely on the same basic kind of carbon-emitting portland cement-based concrete used for the buildings that were wrecked, or it can find a way to utilize more sustainable concrete that dials back carbon emissions.

A BETTER CEMENT

Many people conflate concrete and cement, but cement is an ingredient in concrete. It’s what binds the other components—sand, gravel, water—together. Sand, gravel and water have minimal carbon footprints. The most popular kind of cement—portland cement—has a big one. It’s the world’s second biggest source of carbon emissions.

The world’s largest cement companies no longer even attempt to dodge the problem. Their annual reports, websites, executive speeches, and richly funded R&D programs all emphasize the aim to reach carbon neutrality. Four years ago, trade association meetings hardly touched sustainability; now they’re dominated by the topic. The cement and concrete industries are surprisingly, even hearteningly, blunt about the dangers of its carbon footprint and the need to drastically reduce CO2 emissions. There is no shortage of viable low-carbon alternatives to ordinary portland cement, but nearly every solution is at least a decade away from widespread use.

But there is one viable short-term solution that could dramatically reduce CO2 emissions: supplementing conventional limestone clinker with calcined kaolin clay.

Portland cement derives from limestone that must be baked in giant kilns to 2700 F. Carbon emitting fossil fuels are the only practical option for heating the kilns to such extreme temperatures. In addition, limestone (the Earth’s largest store of carbon) loses its carbon content when it is kilned. A modern cement plant can drive out carbon from thousands of tons of limestone a day; each year, the industry produces the equivalent of 1,200 pounds of cement for every single person on the planet—along with 1,000 pounds of carbon emissions per person on earth.

Following kilning, remaining carbon-free limestone ends up as small pellets known as clinker. The clinker pellets are then ground down to make up the bulk of portland cement. The ratio of clinker in cement is called its clinker factor. The level of clinker factor is the key to cement’s emissions. Cutting the clinker factor in cement by substituting clinker with less-carbon-emitting materials is the key to driving down cement’s carbon footprint.

Which is where kaolin clay comes in. It’s a common clay found all over the world. Some types of kaolin clays are used to make porcelain, but there are a wide variety of types that can be used for other industrial purposes. One purpose is to supplement and replace a large portion of clinker. Heating kaolin clay to around 1300 F calcines it—this makes it reactive enough so that when it combines with some clinker the structural properties of the final cement are undiminished.

Turkey has an abundant supply of kaolin clay, says Kemal Celik, professor of civil and structural engineering at NYU Abu Dhabi. Limestone calcined clay cement, also called LC3, is a material with a much lower clinker factor, and thus far lower carbon emissions, than mainstream cement.

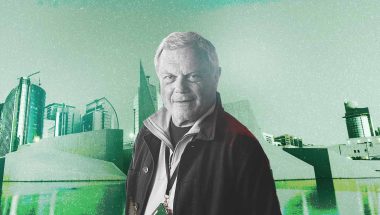

Currently, calcined clay, when combined with ground limestone, can reduce cement’s emission by around 40 percent. Research out of a group led by Karen Scrivener at Switzerland’s EPFL technical university suggests this can eventually be pushed as high as 75 percent. A materials engineer from England, Scrivener is one of the world’s top experts on cementitious materials. She is LC3’s most prominent researcher and chief evangelist driven by the conviction that the material is the world’s only choice to reduce emissions from concrete by the 50 percent dictated by the Paris Agreement’s 2030 climate goals. She travels the world in an effort to get the world to act quickly on its adoption and carries with her a world map that shows all the places in nearly every part of the globe where the necessary raw materials are abundant. Turkey is flush with it.

“LC3 is the only cement available at scale for decarbonizing the industry in time to meet the targets,” Scrivener recently told me at an industry gathering in San Francisco, “but it will take producing millions of tons of LC3 before the end of the decade.”