- | 9:00 am

Why you won’t be eating cell-cultivated meat any time soon

Cell-cultivated meat may appear to be proceeding ever closer to being on sale in the United States, but production, cost, and formulation issues are still bedeviling the one-time disruptors.

This month, the USDA approved labeling of the food once called lab-grown meat. In quick succession the regulatory agency granted Eat Just and then Upside Foods approval of what the startups could call their product. The verdict: cell-cultivated meat.

We may now know how these products will be labeled, but little else can be assumed about the future of technology-enabled meat.

Everyone wants to take guesses, myself included, on when this stuff will make it to market, if it can scale, and whether it will live up to its promise as a boon in the fight against the climate catastrophe. Even academics are turning over the Magic 8 Ball. In a preliminary lifecycle analysis, UC Davis researchers determined that lab-grown meat may fail to be better for the environment than today’s retail offerings.

Beyond endless questions, one thing seems for certain: When and if cell-cultivated meat lands on our plate, it will be blended with non-animal material––essentially plants. Like beef, future meat will depend on basic crops like soybeans and legumes.

WHY CULTIVATED MEAT CAN’T SAY NO TO PLANTS

In Singapore, the only country where companies can legally sell cultivated meat to customers, Eat Just’s chicken offering is roughly 74% chicken cells and 26% plants. CEO Josh Tetrick says that his team is doing what’s best for consumer acceptance. “Our process works, but having binders makes it a more optimal product,” he says. “We could do 100% if we felt like it, but the structure is better.”

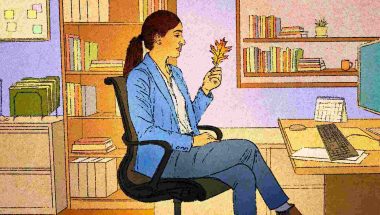

Tetrick isn’t using plants to make us happier; he’s doing it to lessen the load of production. Plants offer more functionality than animal cells, which, uncritically, is mush. Will some percentage of plants in cell-cultivated meat appease vegans or vegetarians? Probably not. Ninety-nine percent of vegans will undoubtedly steer clear. That leaves us with carnivores and flexitarians who won’t change their habits until the stuff is dirt cheap and considerably more delicious.

This hybrid approach goes beyond adding plant-based proteins and oils for better palatability. Plants help cover up what’s missing from meat cells grown outside the body of an animal, allowing companies to replicate the “scaffolding” that gives form to foods like salmon or steak. “We’ll be using plant-based scaffold when the product launches in restaurants,” confirms Aryé Elfenbein, cofounder of Wildtype, which is growing salmon in labs in San Francisco. Most companies, he tells me via email, will need to rely on plants for “structurally complex products.”

Plants also relieve the pressure of producing large quantities of cultivated cells, which no startup can do, so they can get to market more quickly. “With current technology there isn’t a pathway to meaningfully commercialize [a product] that isn’t hybridized,” says Paul Shapiro, author of Clean Meat and CEO of The Better Meat Co.

You know what else plants are? Cheap. “It gets you to cost competitive,” says Lisa Feria, managing partner and CEO of Stray Dog Capital, an early investor in both plant-based and cultivated companies including Beyond Meat, Daring, and Upside. “These initial sales are going to be mixed-in product. You cannot produce enough quickly enough to fulfill demand.” The end game remains 100% cultivated cells, says Feria, “but that comes after a long time of manufacturing and innovating.”

WINNING ON TASTE

To win on taste, cultivated-meat startups are signing on big-name chefs. Upside has Dominique Crenn, Eat Just has José Andres, and Aleph Farms has Marcus Samuelsson. In their kitchens, plant-based is the starting point for development. The goal––a product that’s better for you and the environment (and, oh yeah, animals)––is only worthwhile if it’s also tastier. What percentage of cultivated cells needs to be added to convince us we’re eating meat and not vegetables?

Even with the FDA and USDA on board, in a limited fashion, the nascent industry remains in a bit of a holding pattern. Eat Just’s Tetrick acknowledges that “sometimes, folks will equate regulatory [approval] with scaling,” but is candid in conceding that “the whole world could approve cultivated meat everywhere and that wouldn’t change or enable us to sell one additional pound in 2023,” he says. “The biggest limiting step is scale.”

The announcement earlier this month from JBS, the $8 billion-plus market cap global meat conglomerate—that it’s building a cultivated-meat facility in Spain for BioTech Foods, now owned by JBS—may be the single biggest signal for the industry. Want to bet that the largest meat-processing company in the world is thinking about how to blend cell-cultivated meat with its traditional industrial product to create something meatier than meat? Yet when the doors open it may only produce 1,000 metric tons of cultivated beef per year, which is hundreds of millions tons shy of what will be needed in the future.

For comparison purposes, Eat Just has only sold around 5,000 pounds of cultivated meat. The biggest limitation is size of the bioreactors. “It won’t be until we have much larger vessels, north of 100,000 liters per vessel, that we will really begin to credibly use the word that we’re scaling,” says Tetrick. “Then we can get U.S. distribution.”

In a venture market drying up faster than a California drought, nothing really matters unless money flows. “We’re flabbergasted at the level of retreat in this category,” says Feria. The fundamentals, she says, remain true. While “some companies are taking the wait-and-see approach,” she says, “JBS seems to be the only one to lean forward and wave their hands thru the fog and say, ‘This is still the future.’”

Another stalwart industry player also has its arm raised to participate in a hybrid-meat future (though, not at present cultivated meat): Perdue Farms, the privately held poultry giant. In 2019, the company launched “Chicken Plus.” The frozen food is made from chicken meat and a quarter cup of vegetables––more of a powder––supplied by The Better Meat Co. The line is doing so well, says Jon Swadley, Perdue’s vice president of marketing for its prepared portfolio, that the company launched additional SKUs this past January.

In the spreadsheet of guesses, so many predictions have been proven wrong. With flags planted for hybrid, startups might be wise to focus on signing fewer Michelin three-star chefs and more on improved accessibility. This will require bigger tanks, cheaper inputs, more cells, and lower costs. Investors who have pressed the pause button––hoping to see valuations get more realistic––will have to jump back in, perhaps with fewer startups, if they want to see their bet on cell-cultivated meat exist beyond Singapore, which has fewer than six million residents and is a land mass smaller than any U.S. state.

After a decade of effort, hybrid may be a tacit admission of near-term disappointment, but it also allows the industry to dial back its hubris. This won’t happen overnight. To feed the world, cell-cultivated meat will take money and time. A lot of it.