- | 9:00 am

What will it take for the Middle East to become a manufacturing hub?

The region has a strategic location to serve several growing markets, demographic bonuses, monetary stability, and improved intra-regional relationships on its side

If you have been keeping up with the news these past few years, it’s been a steady dopamine drip: “We are making UAE a magnet for manufacturing … technology has the potential to revolutionize the way we make almost everything in Saudi Arabia.” And be-still-my-heart: “We are poised to control our future.”

Countries that are serious about manufacturing have industrial strategies. The UAE and Saudi Arabia have one. So does Qatar.

In January, speaking at the World Economic Forum in Davos, Bandar Alkhorayef, the Industry and Minerals Minister of Saudi Arabia, said: “With our great location, access to different markets (and natural resources), as well as our most important asset — our people and our talent — we can be a serious player in attracting investments in manufacturing.”

The Middle East has the economic means and socio-political willingness to take the opportunity to become a manufacturing hub. The several mega-projects — from biopharma and bioplastics to aluminum, electric vehicles, and hydrogen fuel — are a specific window of opportunity.

SMART GROWTH STRATEGY

Reading the economic signs of the times far better, “manufacturing hubs” in various countries are employing more people, making manufacturing processes smarter, and reducing waste, which means that local manufacturers can charge less for their services. It’s a smart growth strategy: reduce the bottom line and increase profit.

Factory construction is proceeding more rapidly than at any time in recent memory, heralding what may be a resurgence in domestic production powered by a move away from long, fragile supply chains and by the infusion of billions of dollars in public investment.

“Since 2019, the pandemic, the geo-political tensions, and climate-related disruptions have questioned the reliability of world supply chains. Thus, the potential for localization of production has grown for resilience and economic development purposes,” says Alejandro Escobar, Partner at Kearney Middle East & Africa.

Backed by a robust business ecosystem, and Operation 300bn initiative to turbocharge the industrial sector, the UAE is taking the lead in high-value manufacturing. The country is eyeing to increase the industrial sector’s contribution to the country’s GDP to over $80 billion by 2031. The Make it in the Emirates initiative – a call to industrialists, investors, innovators, and entrepreneurs to manufacture in the UAE – further strengthens the nation’s reputation.

That optimism tallies with industrialists who are convinced that this is the time to make the region the next manufacturing hub for the regional and global markets.

The UAE is already an important global aluminum production hub, accounting for 10% of global production. Emirates Global Aluminium (EGA) supplies more than 50 countries, the biggest made-in-the-UAE export after oil & gas.

“There is a clear opportunity to grow more – our business, manufacturing in our local supply chain, and the local downstream industry that makes everything from car parts to window frames using our metal. Currently, we spend around $1.7 billion yearly in our local supply chain, and we supply about 10% of our metal to local customers,” says Abdulnasser Bin Kalban, Chief Executive Officer of Emirates Global Aluminium.

Patrick Stillhart, CEO of Saudia Dairy and Foodstuff Co., says the Middle East are re-evaluating their reliance on global supply chains and considering a shift towards domestic manufacturing. “The pandemic exposed vulnerabilities in global supply chains, disrupting the flow of goods and highlighting the risks associated with overreliance on distant suppliers.

As a result, countries in the region had to explore ways to enhance local manufacturing capabilities. “The financial losses and demand fluctuations experienced during the pandemic have made countries realize the importance of reducing dependency on external sources for essential goods. By investing in domestic manufacturing, they can ensure a more reliable and self-sufficient supply of critical products,” adds Stillhart.

Furthermore, strengthening domestic manufacturing gives countries strategic independence, reduces the reliance on international trade and minimizes the risk of disruptions during times of crises or geopolitical tensions.

While the extent of the shift towards domestic manufacturing varies across countries in the Middle East, the pandemic has undoubtedly highlighted the importance of local manufacturing for resilience, self-sufficiency, and economic development, he adds.

Countries are staking claims on lucrative segments and aiming to gain first-mover advantage. For example, TONOMUS is building advanced digital infrastructure in Saudi Arabia’s NEOM project, and Mubadala in the UAE is focused on localizing high-tech products.

For a decade, the manufacturing sector in Saudi Arabia and the UAE has been dominated by oil, gas, and petrochemical production.

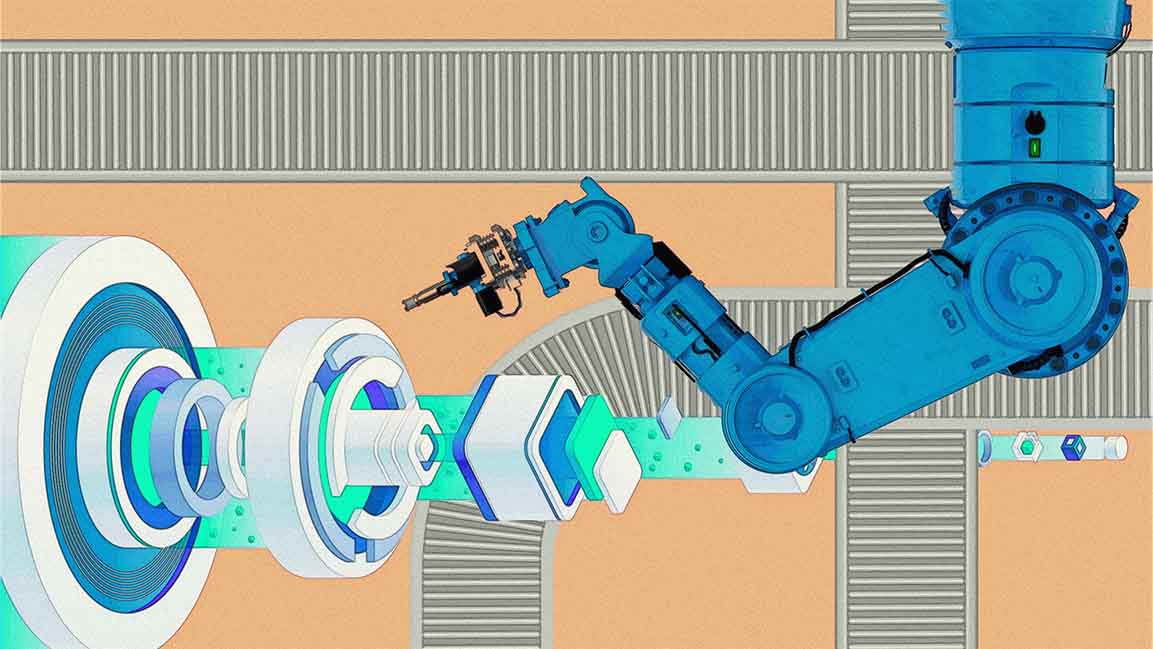

Now, to create a competitive economy, these countries are employing advanced technology, such as the Internet of Things, 3D printing, robotics, and artificial intelligence, in a mix of manufacturing industries such as food and building material products, machinery and equipment, products, mining, and automotive.

Qatar aims to double the value of its manufacturing sector – currently worth $11.4 billion – to diversify its economy. Last year, it launched the Advanced Manufacturing Hub.

With economies stepping up their efforts to become major players in the global technology scene, a study found that high-technology manufacturing products present a $125 billion economic opportunity for the region. The report added that three products – semiconductors, sensors, and robots for industrial or general-purpose use – could provide an estimated $25 billion in revenue by 2025.

AN ATTRACTIVE BASE

Many things are going for the region to become an attractive and competitive manufacturing hub: strategic location to serve several growing markets, demographic bonus, monetary stability, improved intra-regional relationships, and social changes favorable to immigration.

“The Middle East, with its strategic geographical location facilitating access to markets in Europe, Asia, and Africa, coupled with robust infrastructure and a government-driven initiative to diversify economies for long-term stability, possesses immense potential to emerge as a manufacturing powerhouse on the global stage,” says John Iossifidis, GCEO at Al Ghurair Investment, a business group with operations in properties, construction, energy, and mobility sectors.

The region, especially UAE, Saudi Arabia, and Qatar, can attract skilled people from around the world, well-developed port infrastructure and global shipping connectivity, its central location in the world, and energy availability.

There’s also a supportive ecosystem, including direct subsidies and tax breaks to reduce long-term operating expenditures, and regulatory and policy reforms.

Pointing out UAE’s business-friendly regulatory framework, including investment incentives that promotes a favorable environment for manufacturers, Iossifidis says, “The country’s focus on advanced technology, research and development nurturing innovation are conducive to manufacturing growth.”

Additionally, the GCC countries are undertaking huge investments (mega-projects) in infrastructure and high-technology sectors, which provides demand and visibility of demand to investors, adds Escobar.

The manufacturing industry has been on the rise in recent years, with many major players eyeing the region as a potential hub for production and innovation. Also, considering the uncertainty in the global market, experts say, there is an opportunity for the region to grab more of the pie.

By reducing trade barriers and fostering economic cooperation with neighboring countries, Stillhart says Saudi Arabia facilitates regional economic integration and enhances market access for Middle Eastern businesses.

“By encouraging renewable energy adoption, resource efficiency, and implementing green certifications, businesses are encouraged to consider manufacturing because of the positive impact it will have on the environment.”

ADVANTAGEOUS GEOGRAPHICAL LOCATION

“The region has high potential. It’s an optimal location to distribute to the Arabian Peninsula and North-Eastern Africa, with more than 600 million consumers. Mature and developing maritime infrastructure, particularly in Saudi Arabia, opens the door to the main Asia to Europe shipping trade route, accounting for 10-15% of global container trade,” says Escobar.

The UAE is also enhancing its capacity to handle large-scale construction projects through significant investments in logistics facilities, ports, and transportation networks.

“By leveraging its advantageous location and robust infrastructure, the UAE stands a strong chance to establish itself as a global leader in manufacturing within the construction industry, facilitating smooth connectivity and efficient transportation of construction materials, equipment, and finished products,” adds Iossifidis.

Vouching UAE’s efficient logistics infrastructure, Kalban says, “EGA moves more than 20 million tonnes of materials around the world each year, including many millions of tonnes into and out of the UAE. The UAE’s logistics infrastructure contributes to supply chain resilience. But supply chains also have a significant opportunity to grow the local industry further.”

He adds EGA’s demand can lead to the development of new industries in the UAE to supply it. “We are already making progress and have announced some early-stage agreements that could lead to exciting developments.

CHALLENGES IN HUMAN CAPITAL

While all this is good, elevating the skills levels of the workforce is vital to drive greater manufacturer interest in the region. The GCC countries have challenges in terms of human capital. Apart from Jordan, the whole region has higher labor costs than most Asian or North African manufacturing destinations, says Escobar.

“While this can be addressed with automation, the challenge is modern manufacturing requires high-skilled workers. The region must be able to attract foreign talent to fill in the needs and help build those capabilities in-house.”

To address it, countries like UAE and Saudi Arabia, in collaboration with global tech giants, are investing in skill development and training programs to cultivate a competent workforce to meet the specialized demands of modern manufacturing.

“Manufacturers are more likely to establish operations in regions where a skilled talent pool is readily available, as it reduces training costs and accelerates the pace of operations,” says Iossifidis. “Ongoing skill enhancement initiatives will play a pivotal role in attracting manufacturers and fostering economic growth.”

Although the region’s labor cost is comparatively higher, experts say low energy and raw materials costs and other enablers often compensate for it.

“Imports-exports are backed-up by infrastructure and with increasingly efficient and simplified border administration; access to finance is expanding and increasingly inclusive to foreign investors; while legal and regulatory environments are becoming stable and transparent, which amplifies the investors trust,” says Escobar.

CLOSER REGIONAL PARTNERSHIP

The argument in favor of a closer regional partnership, and free trade agreements is that it would allow the region to produce better quality and lower cost products that could better compete on the international market with products made in China.

The region has a vibrant trade in the raw materials and inputs that go into a variety of products, and many companies have designed their supply chains to run back and forth between the countries, taking advantage of natural resources, worker skills or favorable government policies.

But experts say a major facilitator of the manufacturing ambitions of the countries is the cohort of multidisciplinary free zones that are instrumental in attracting businesses to invest and manufacture products and services locally. For example, Dubai’s Jebel Ali Free Zone has nearly 800 manufacturing companies.

Apart from special economic zones that can foster manufacturing hubs to export value-added products, experts say it’s important to continuously advance infrastructure, including ports, transportation networks, and industrial zones, to build strengthened logistics and supply chain management.

“Concurrently, continued investment in technological advancements, promotion of innovation, and cultivation of a skilled workforce are essential components,” says Iossifidis. “Creating a business-friendly environment, prioritizing research and development, and attracting foreign investment also serve as driving forces to enhance the manufacturing competitiveness.”