- | 9:00 am

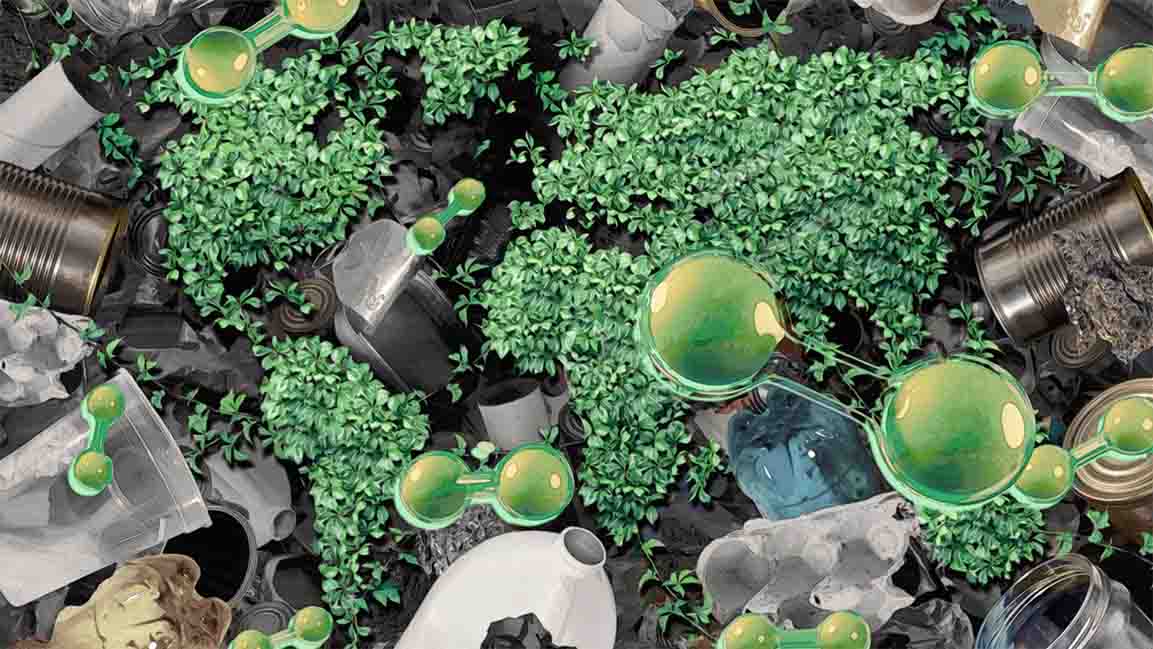

Companies in the Middle East are turning waste into energy. Fueling the green hydrogen economy

Experts say producing waste-derived fuels is the pathway to remove thousands of tons of CO2 annually by creating fuel cell-grade hydrogen.

Recently, in a ground-breaking initiative, Dubai launched the world’s largest waste-to-energy project, the Dubai Waste Management Center (DWMC). It is a move towards a greener future and a key to the hydrogen economy in the MENA region.

As the DWMC gears up to commence its operations, producing 80MWh of renewable energy by processing 2,000 tonnes of solid waste, a dozen promising companies across the region are exploring cutting-edge technologies to convert various types of waste into clean hydrogen fuel.

These innovators, eager to capitalize on the momentum, seek to drive the hydrogen economy forward, offering a greener, more efficient energy solution.

Egypt’s Green Planet for Sustainable Environmental Solutions recently signed an MoU with US-based H2-Industries for a waste-to-hydrogen plant at East Port Said/Suez Canal Economic Zone. Fueled by organic and non-recyclable plastic waste, the plant will yield clean hydrogen fuel, marking a significant milestone in sustainable energy solutions.

Another path-breaking waste-to-hydrogen project has debuted in the Sultanate of Oman at an estimated investment of $1.4 billion. The Public Establishment for Industrial Estates (Madayn) and H2-Industries Inc have partnered to establish the facility on a 200,000 sq meter plot along the Omani coast.

As a part of the deal, H2-Industries will employ its proprietary technology to convert landfill waste through a thermo-chemical process, producing green hydrogen and pure carbon dioxide. The green hydrogen will then be transported and stored using the company’s patented Liquid Organic Hydrogen Carrier (LOHC) technologies, providing efficient extraction and conversion to electrical energy for end-users.

With plans to process approximately 1 million tonnes of municipal solid waste annually, the project is expected to yield around 67,000 tonnes of green hydrogen and 1 million tonnes of valuable carbon dioxide. These outputs have an estimated combined export value of $268 million annually.

“This is an exciting opportunity, one that will take the tonnes of waste collected in Oman and turn it into green hydrogen,” says Michael Stusch, Executive Chairman – H2-Industries.

“The investment into Oman will make a substantial contribution to the country’s waste management strategy and demonstrates how fighting climate change and enhancing environmental protection can go hand in hand and benefit all stakeholders.”

According to Stusch, the company’s projects in Egypt and Oman are poised to revolutionize green hydrogen production costs. By 2026, they anticipate producing green hydrogen at an impressively low price of $2-$3 per kilogram, which is expected to plummet further to less than $1 per kilogram by 2030.

Comparatively, hydrogen produced using renewable electricity is estimated to cost $3-$8 per kilogram, as published by the International Energy Agency (IEA) in its 2021 Global Hydrogen Review.

THE POWER OF WASTE

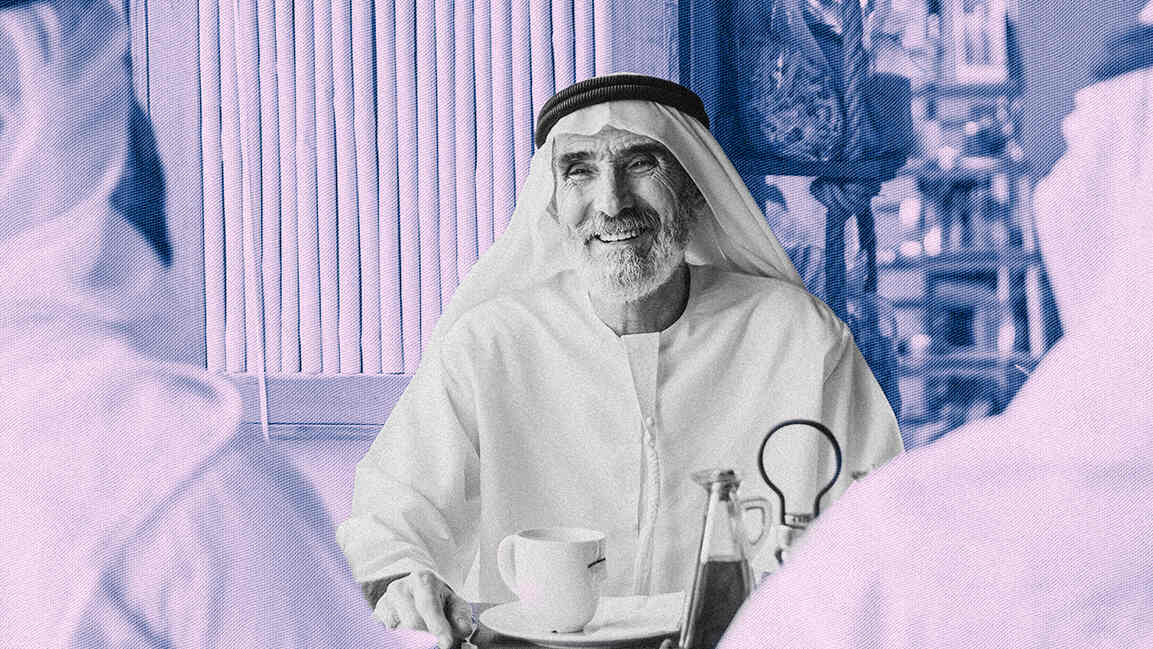

One of the biggest developments in the space came in 2022, when UAE-based BEEAH Group teamed up with Chinook Sciences, an innovator in waste-to-fuel technologies in the UK, and Air Water, a Japanese conglomerate with businesses in industrial gas production, to produce fuel cell grade hydrogen from waste wood and plastic.

“The waste-to-hydrogen plant is an innovation that will enable us to eliminate the challenge of certain types of waste wood and plastic while also producing fuel cell grade hydrogen, which is a solution for emissions-free mobility of the future,” said Khaled Al Huraimel, Group CEO of BEEAH Group.

The waste-to-hydrogen plant’s ambitious plans have also comprised an on-site green hydrogen dispensing station designed to fuel multiple vehicles.

According to energy transition researcher Owais Ali, recovering hydrogen from waste generates clean fuel and helps deal with the growing amount of non-recyclable waste polluting our environment. “Environmentally friendly hydrogen production will be substantially less expensive than fossil fuel production.”

By 2030, the global green hydrogen production market is expected to reach $1 trillion.

As per its Hydrogen Leadership Roadmap, the UAE’s objective is to be a hub for the export of green hydrogen, targeting 25% of the global market. Overall, the country aims to treat 75% of solid municipal waste by 2025 and 85% by 2035, as well as reduce solid municipal waste generation to 1.4 kilograms per person a day by 2025, according to figures provided by the organizers of the Ecowaste forum at Abu Dhabi Sustainability Week.

THE FUEL OF THE FUTURE

The production of waste-derived fuels is a clean energy technology experts believe is the pathway to remove thousands of tons of CO2 annually by creating fuel cell-grade hydrogen.

“For the next three to five years, we’re looking at waste-to-hydrogen plants as the most important business followed by storage for renewables (photovoltaic and wind) to make them baseload capable with our Liquified Organic Hydrogen Carrier (LOHC) storage technology,” says Stusch.

He points out that the company’s waste-to-hydrogen technology processes garbage, plastic waste, and sludge to produce green hydrogen at half the levelized cost of solar or wind-powered electrolysis.

MENA countries are signaling their readiness to be pivotal in transitioning to a more sustainable future and be a significant player in the global clean energy market.

According to Siemens Energy technology, which supports similar waste to energy power plants in the region, there are already a number of technologies available for the production and use of hydrogen.

“To make these technologies economically and efficiently viable, they must be further developed and scaled up under real-world conditions. To further accelerate the decarbonization of the entire energy system, we intend to keep developing our hydrogen portfolio, including the industrial-scale Proton Exchange Membrane electrolyzers and hydrogen-ready gas turbines,” says a Siemens Energy spokesperson.

Even Bosch, which operates along the entire hydrogen value chain, will have invested nearly $2.87 billion in developing and manufacturing its H2 technologies between 2021 and 2026, and plans to generate sales of roughly $5.6 billion with hydrogen technology.

Ali notes that with the progress on large-scale investment, support, and the much-needed public awareness of replacing fossil fuels with low-carbon alternatives, the time is ripe for “waste-to-hydrogen technology to play a significant role in the global transition towards carbon neutrality by replacing carbon-emitting fossil fuels with affordable renewable energy.”