- | 9:00 am

Stronger, prettier, and better for the environment: Why stone is making a comeback in architecture

Stone is one of the world’s oldest materials. Why did we ever stop using it?

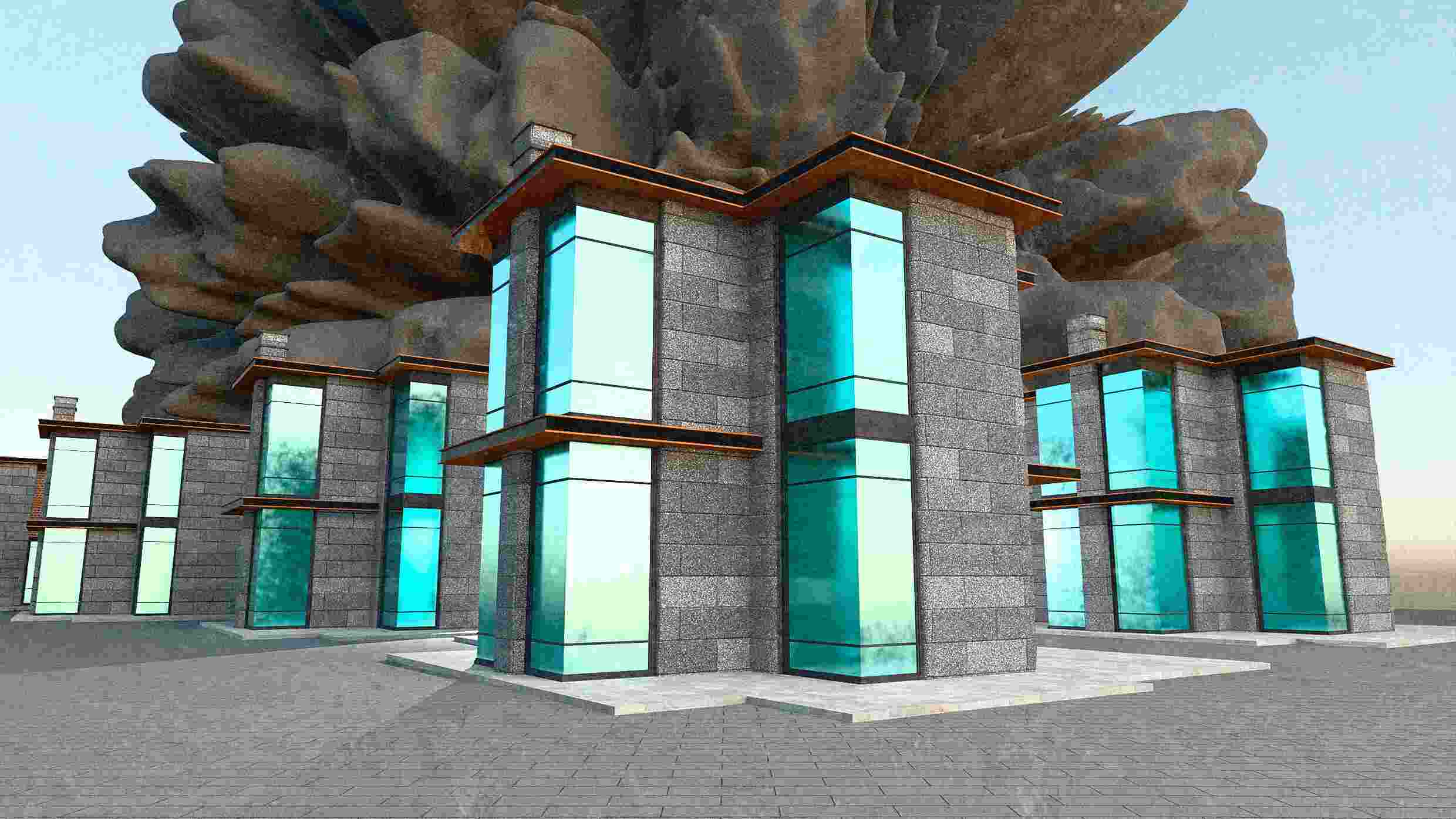

In 2018, a peculiar building opened its doors on a quiet street of central London, and almost immediately, it turned into architectural marmite: some hated it enough to order its demolition, others adored it enough to honor it with the RIBA Stirling Prize, Britain’s top architecture award.

The building in question was designed by local architect Amin Taha. It is known as 15 Clerkenwell Close and the controversy may surprise you, because in a sea of brick Victorian dwellings, the newcomer stood out (apparently too much) with its load-bearing, rough-hewn limestone structure.

The building ended up dodging the wrecking ball, and in the process it put stone, a virtually forgotten building material, back on the map. It also prompted an important question: Can this millennia-old natural material, which was supplanted by concrete, steel, and mass-produced bricks, be the sustainable building material we’ve been looking for?

A few years ago, four architecture students at the Liverpool University were inspired by Taha’s ambitious project and set out to learn more about the benefits and limitations of natural stone as a building material. Their research has culminated in a thesis project called Stone Reform, which explores what would happen if we stopped building with concrete and started building with natural stone instead. “We definitely didn’t have a strong stance at the beginning, but we definitely ended up with a stance that stone makes a lot more sense over choosing concrete,” says Toby Barlow, who worked on the project with fellow students Matthew Davies, Thomas Phillips, James Watson.

Concrete, of course, is the most commonly used construction material in the world—primarily because building with it is cheap and quick, and concrete is so malleable it has been likened to “liquid stone.” Making it, however, requires a lot of water, and tremendous amounts of energy, and because that energy comes from fossil fuels, concrete accounts for 8% of global CO2 emissions.

Meanwhile, stone is one of the world’s oldest materials. From the Ancient Pyramids of Egypt to medieval castles in France, to the Great Wall of China, stone has shaped civilizations across thousands of years. It comes in a variety of types like granite, slate, travertine, and limestone (which is also commonly used as an aggregate in concrete). It is strong—typically two and half times stronger than concrete—durable, plentiful, and fire-resistant. It requires low level of energy to make and has one third of the carbon footprint of concrete.

Why did we ever stop using it?

The answer has to do with numbers. In a book titled Architecture: From Prehistory to Climate Emergency, the British author and architecture historian Barnabas Calder argues that the use of concrete exploded when the heat required to make it stopped being so expensive. In other words, burning coal, oil, and gas became cheaper than burning charcoal, and the abundance of fossil fuels made concrete an easy choice.

Today, the equation hasn’t changed all that much, and concrete remains cheaper than stone. As part of their research, Barlow and his classmates chose to analyze how stone would compare to concrete if applied to a real-life case study. They chose Liverpool Waters, or Liverpool’s $6.9 billion, 150-acre bid to transform the city’s old docklands into a waterfront neighborhood. They found that building with stone would save a whopping 51% in embodied carbon compared to concrete. It would, however, incur a 16% cost increase.

For Barlow, the reasons stone remains more expensive are twofold, at least in the U.K. First, the infrastructure isn’t currently optimized enough to use stone at scale, with most quarries lacking the machinery to cut the material into large building blocks. Instead, the stone is often crushed into small chunks and turned into aggregate for concrete. “The irony is that we’re crushing up a material that is very strong and making a material that is weaker through a lot of heat,” he says.

The second reason why stone remains pricier than concrete has to do with the lack of skilled craftsmanship. Building with stone requires trained stonemasons; it also means quantity surveyors have to learn how to price out stone, structural engineers have to learn the capabilities of stone, and contractors have to learn how to build with stone. “We’d need the whole industry to upscale,” says Barlow.

More policies and better regulations on embodied carbon will likely help speed up how fast the industry adopts stone, but already, a movement is forming, and some are calling it the “New Stone Age.” In the U.K., it is spearheaded by architects Amin Taha, Steve Webb, and Pierre Bidaud, whose company, the Stonemasonry Company, is doing research in structural stone beams and columns. In the U.S., Polycor, which is the largest quarrier of natural stone in the world, is on a mission “to make people fall in love with natural stone again” with a wide variety of stone bricks, tiles, and pavers. And in France, which has a long legacy of stone buildings (“Paris stone” can be found throughout the capital), most French quarries issue a strength certificate, which helps architects use stone for structural purposes and not just for cladding.

There are, of course, limitations to the material. It’s a finite resource, which means we can’t exploit it forever. Quarrying it can also be noisy, polluting, and harmful to biodiversity. When quarries are depleted, they are also left as gaping holes that can fill up with water and form dangerous quarry lakes. But there is proven potential in these voids. In 1999, a disused chalk quarry southeast of London was transformed into a sprawling shopping center. More recently, three abandoned stone quarries in rural China were transformed into open-air libraries and performance. Various quarries in the U.S. have also been converted into botanical gardens, adventure parks, and reservoirs for emergency drinking water.

Barlow admits that the higher cost of stone means it’s not realistic for the material to entirely replace concrete, but the more architects and developers use it, the faster the cost will come down. “We definitely feel that stone has a part to play along with other materials [like timber],” he says. “Stone should be a part of tool kit of materials that architects can use to decrease carbon.”