- | 8:00 am

Satya Nadella on the bigger vision behind Microsoft’s new battery

Working with a national lab, the software giant used AI to tackle the flaws of today’s lithium batteries—and pave a new path for scientific discovery.

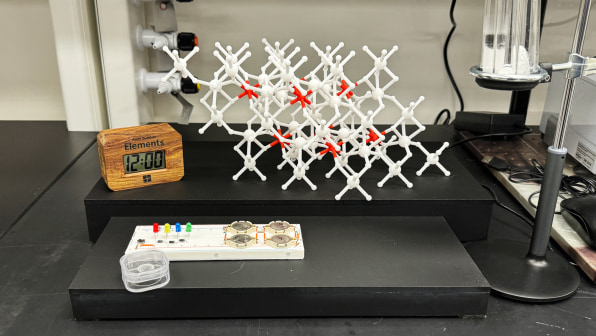

Recently, Microsoft built a clock.

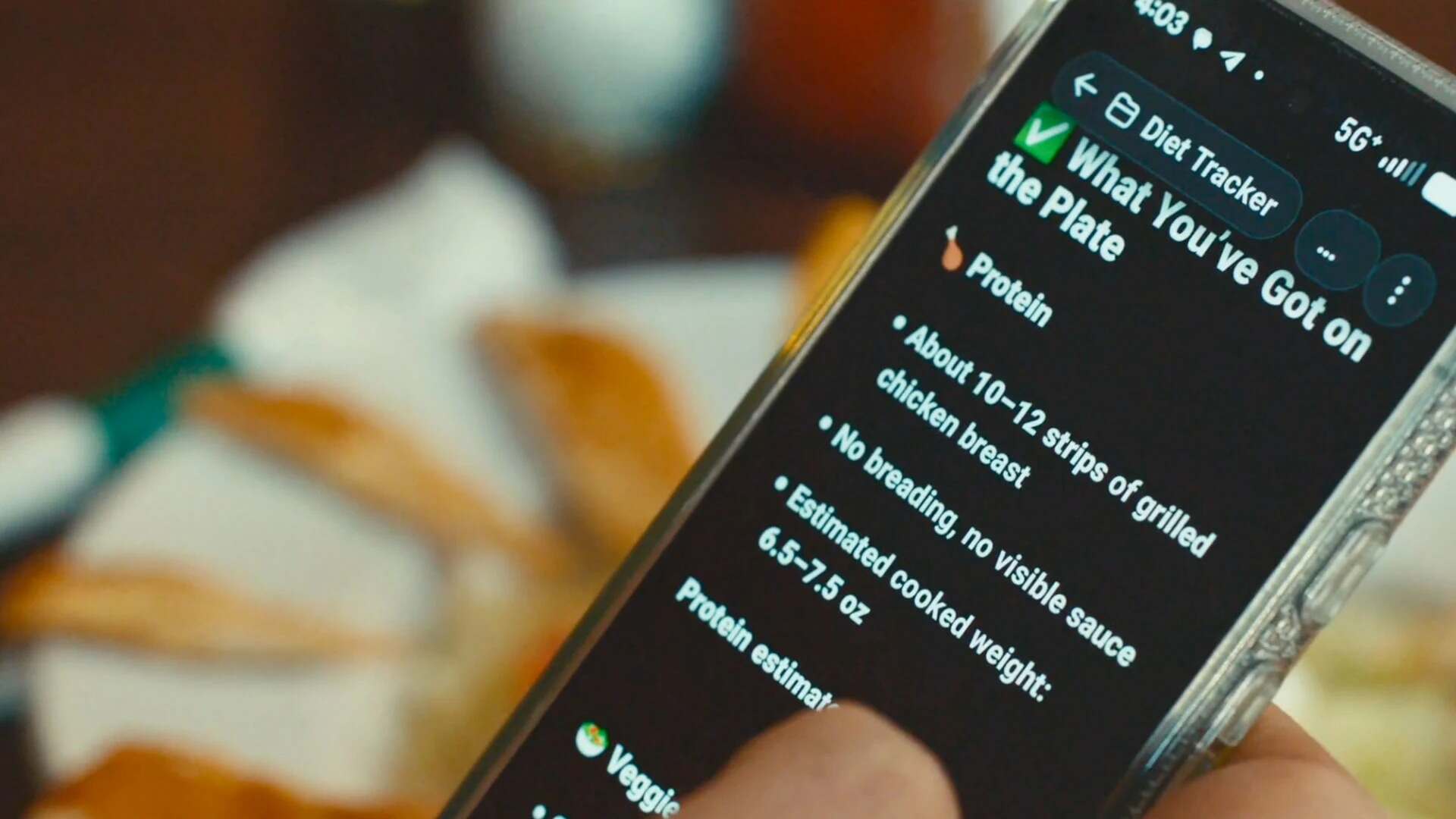

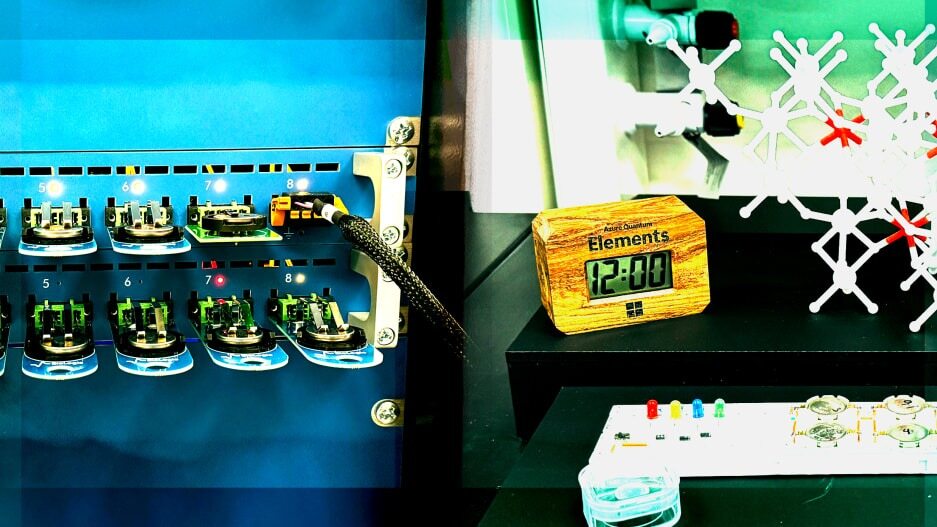

Well, “built” may be overstating things. Members of the company’s quantum computing team found a small digital clock in a wood case on Amazon—the kind you might mistake for a nicer-than-usual trade show tchotchke. They hacked it to run off two experimental batteries they’d created in collaboration with staffers at the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL). Then they dressed up its enclosure by adding the logo of Azure Quantum Elements, the Microsoft platform for AI-enhanced scientific discovery that had been instrumental in developing the new battery technology.

The point of this little DIY project was to prove the batteries worked in a visceral way: “You want to have a wow moment,” explains Brian Bilodeau, the head of partnerships, strategy, and operations for Azure Quantum. And the person the quantum team hoped to wow was Microsoft CEO Satya Nadella.

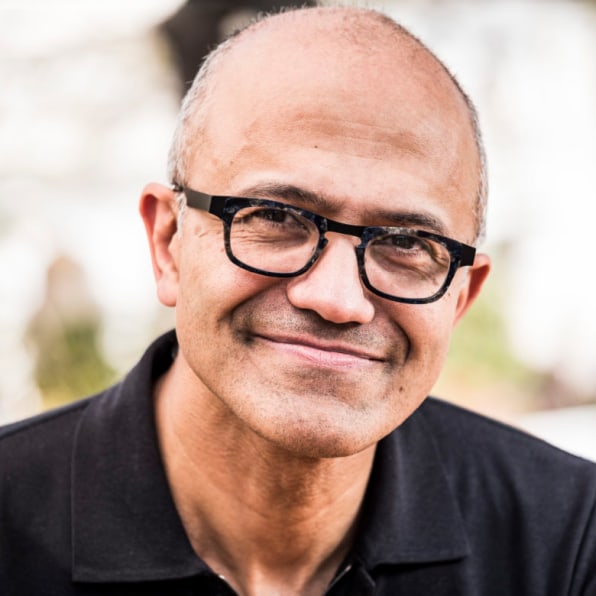

Not that getting Nadella’s attention was such a daunting prospect. Throwing vast amounts of Azure high-performance computing (HPC) resources at a big, hairy technical challenge such as materials research is the sort of challenge he’s predisposed to take a personal interest in. Still, the tangible evidence of success made for a memorable moment: “I was very, very excited to see it come through,” Nadella remembers.

The coin-sized CR2032 batteries powering the clock looked like the ones you might find in a pocket calculator or garage door opener. But on the inside, they used a solid-state electrolyte that replaces 70% of the lithium in garden-variety batteries with sodium. That holds the potential to address multiple issues with lithium batteries as we know them: their limited life on a charge, shrinking capacity over time, subpar performance in extreme temperatures, and risk of catching fire or even exploding. In addition, reducing lithium use in favor of cheap, plentiful sodium could be a boon to the fraught battery supply chain.With further development, the new material could benefit the myriad aspects of modern life that depend on batteries, from smartphones to EVs to the power grid. But Microsoft, being Microsoft, regards all this promise first and foremost as proof of Azure Quantum Elements’ usefulness to the customers it’s designed to serve. Unveiled last June, the cloud service is currently a “private preview” being tested by organizations such as Britain’s Johnson Matthey, which is using it to help design catalytic converters and hydrogen fuel cells.

Using the evocative term for a tech company living with its products like a customer would, Microsoft senior director of partnerships for chemistry and materials Nathan Baker—who joined the company in 2022 after a dozen years at PNNL—cites the foray into battery research as an example of Microsoft eating its own dog food. When developing a new product, he says, “the first thing you [say] is, ‘Well, let’s, let’s prove to ourselves that it works—let’s try it out for ourselves.”

Nadella, too, emphasizes that the learnings from the battery experiment—which the company dubbed “Project Bottle Rocket”—will go back into improving the Azure Quantum Elements platform. “At the end of the day, it’s about being able to democratize powerful technology so that others can build more technology,” he says. “I sort of refrain from talking about ‘our great scientific achievement.’ That’s not us.”

BEYOND TRIAL AND ERROR

Even the scientists at 59-year-old PNNL, where building better batteries has long been a key research area, see their collaboration with Microsoft as being about bigger ambitions. Based at a sprawling 664-acre campus in Richland, Washington, 200 miles to the east of Microsoft’s Redmond HQ, its scientists know well how bogged down lab research can get in dead ends. A century and a half ago, Thomas Edison famously tested thousands of filaments before finding one that would make the electric light bulb practical. That willingness to try anything and everything—known as the Edisonian approach—is still reflected in scientific discovery today.

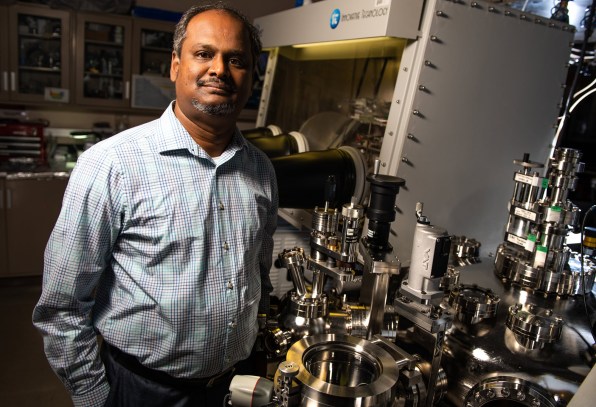

“It’s always trial and error,” says Vijay Murugesan, head of PNNL’s Material Sciences Group. “Something comes up in my dreams or the shower, and then I come in and spend two years testing whether it works or not. And then you go back and do that cycle again for a decade. The success rate is not that great, to be honest.”

The implications of that traditionally poky pace are sweeping. PNNL’s research initiatives cover ground ranging from coastal science to national security, “The timescale on which we do discovery today isn’t fast enough to meet some of the global challenges we’re trying to address,” says associate laboratory director and chief digital officer Brian Abrahamson. “And if we can move the needle on that significantly, that’s a huge deal.”Enter Microsoft. Virtualizing some of the up-front work and turning it over to the company’s newest, fastest computers could change everything in the years to come. As Nadella puts it, “We have to take 250 years of progress in chemistry and compress it into 25 years—and the only way to do that is by having a lot of computational simulation power.”

In the case of the new battery technology, Microsoft began with a data set of 32.6 million materials. Using Azure Quantum Elements HPC resources to run simulations and AI models, it reduced the field of contenders to 500,000, then 500, then 150, then 18. The company consulted with PNNL material-science experts to further winnow the list and ultimately identified the lithium-sodium material as worthy of lab synthesis and testing.

Zipping through so many possibilities and rejecting most of them in the cloud “only took us two weeks,” says Jason Zander, Microsoft’s executive VP of strategic missions and technologies and a 31-year veteran of the company. “That’s dramatically faster than the traditional approach, which sometimes can take years.” In total, the battery project has been underway for about a year, from its inception through the fabrication of around 40 test batteries. (Along with powering the clock, they’ve also been used to light up LEDs in the colors of Microsoft’s corporate logomark: red, yellow, blue, and green.)

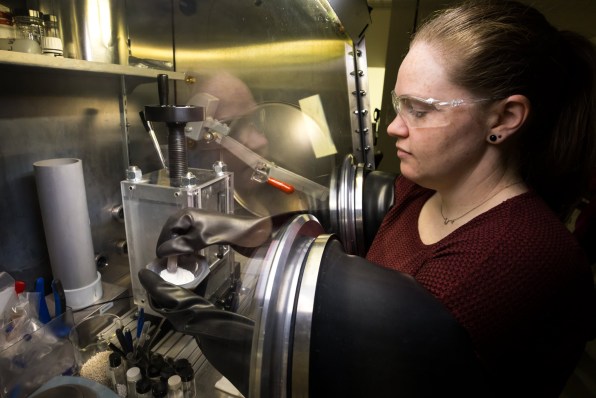

The fact that two weeks of high-performance computing was just one element in a year-long research effort is evidence that there’s still a crucial physical element to testing a new material such as Microsoft’s lithium-sodium compound. During my visit to PNNL, materials scientists Shannon Lee and Dan Thien Nguyen walked me through some of the intricate steps involved in validating the material—grinding it up with a mortar and pestle, subjecting it to three tons of pressure, melting it at up to 600 degrees Celsius, inspecting it with a microscope.

Technical derring-do is sometimes required. Having produced samples of the material Microsoft identified through algorithmic investigation, PNNL’s researchers found it wasn’t exactly a breeze to work with in the real world. “After 30 minutes of just open air, it’ll actually absorb moisture from the air and turn into kind of a goo,” says Lee.

Watching Lee and Nguyen at work, you get the feeling that old-school lab experimentation of the sort that Thomas Edison would instantly recognize isn’t going anywhere—it’s just going to come later in the process, after computers have given it some direction. It’s not a given that a government facility would turn to a platform provider such as Microsoft for help on this front—another Department of Energy site, the Oak Ridge National Laboratory, is home to the world’s fastest supercomputer. But PNNL prides itself on its willingness to embrace the nimble, on-demand resources that cloud services such as Azure Quantum Elements can offer.

“We are exceptionally favorably disposed to commercial partnerships in computing,” says PNNL deputy director for science and technology Tony Peurrung. He adds that “being in Microsoft’s backyard” hasn’t hurt the lab’s relationship with the software giant. (It also has deals with other cloud-computing providers.)

IT’S NOT QUANTUM COMPUTING (YET)

By this point, I’m probably overdue to bring up an important point about Microsoft and PNNL’s battery. Despite a platform called Azure Quantum Elements playing a crucial role in developing it, quantum computing was not involved. And yet the Microsoft employees involved do work in the company’s quantum computing group, making the achievement decidedly quantum-adjacent.

All of this is explained by the current state of quantum computers. By leveraging quantum physics, the technology dispenses with a classical computer’s bits—each capable of representing only a one or a zero—in favor of “qubits” that can represent a zero, a one . . . or both at the same time. This mind-bending advance could lead to computers powerful enough to swiftly perform calculations that even today’s fastest computers couldn’t complete in several lifetimes. That would make them ideally suited for jobs with an insatiable hunger for computational resources, such as scientific discovery.

Along with other tech giants such as IBM and Google as well as numerous startups, Microsoft is betting big on quantum’s potential. But “potential” is the right word. Decades after it was conceived, the technology is still a work in progress, not a commercial reality. Experts can make only educated guesses about when it might be ready to tackle serious tasks with epoch-shifting impact: “We do believe it’s measured in years and not decades,” says Krista Svore, Microsoft’s VP of advanced quantum development.

Meanwhile, computers of the more conventional type are nowhere near tapped out. Equipped with massive quantities of ever-more powerful GPU chips, they’re capable of performing increasingly transformative AI feats—not at some unspecified point in the future, but right now. This advance enabled high-performance computing in the cloud—basically, supercomputing as a service—such as the Azure resources Microsoft used to pinpoint its battery material.

The turn of events surprised even quantum champions such as Nadella. “I was thinking, quantum is the next big accelerator,” he told me. “It turned out the GPU was the next big accelerator.”

However quantum computing develops from here, it’s unlikely to entirely displace high-performance computing of the sort Microsoft employed to find its battery material. In the future, Svore predicts, scientists will be able to call on “a tightly integrated system among these three capabilities—HPC, AI, and quantum—that ultimately drives a more accurate solution for types of problems that we can’t solve today.”

Once that era arrives, the avenues for exploration could be unlimited. “What’s always amazing to me is the amount of things that we somehow take for granted, but realize we don’t even [comprehend],” says Zander. “Like we can’t even tell you precisely how photosynthesis actually works.”

For now, Microsoft’s collaboration with PNNL offers one concrete case study in how Azure Quantum Elements can fit into the discovery pipeline. The fundamental relatability of batteries explains why the company settled on them as a research subject: “Quite frankly, it’s something that people understand,” says Bilodeau.

Nobody I spoke with at Microsoft or PNNL got very specific about how the batteries presently in the lab might lead to ones that would be produced at scale. “A lot of work needs to be done before we put something in a consumer’s hand,” acknowledges Murugesan. Obvious short-term steps include fabricating and testing larger batteries, such as the “pouch” cells widely used in consumer electronics, EVs, and other items.

Could there be an eventual Microsoft-sized business opportunity here? The company doesn’t seem indifferent to that possibility, though the details are seemingly TBD. (For what it’s worth, I was asked not to snap any photos of a PowerPoint about the project on the grounds that it might contain information not yet patented.) “Microsoft isn’t going to go into battery manufacturing, and PNNL’s not going to go into battery manufacturing,” muses Bilodeau. “It would be something where we would partner with someone to make the batteries.”

Regardless of what happens with the technology, Microsoft has already achieved the initial goal it set for itself. “The reason I love this is because it proves—not just in theory, but in practice—that you can complete the loop,” says Nadella. “You can [create] a new material that actually works.” And maybe even do it at a clip that would have been unimaginable just a few years ago.