- | 1:00 pm

Qatar breaks ground on world’s biggest 3D-printed school project

Curved, dune-inspired schools showcase 3D printing’s design freedom, cementing Qatar’s global role in sustainable, future-ready infrastructure by 2025.

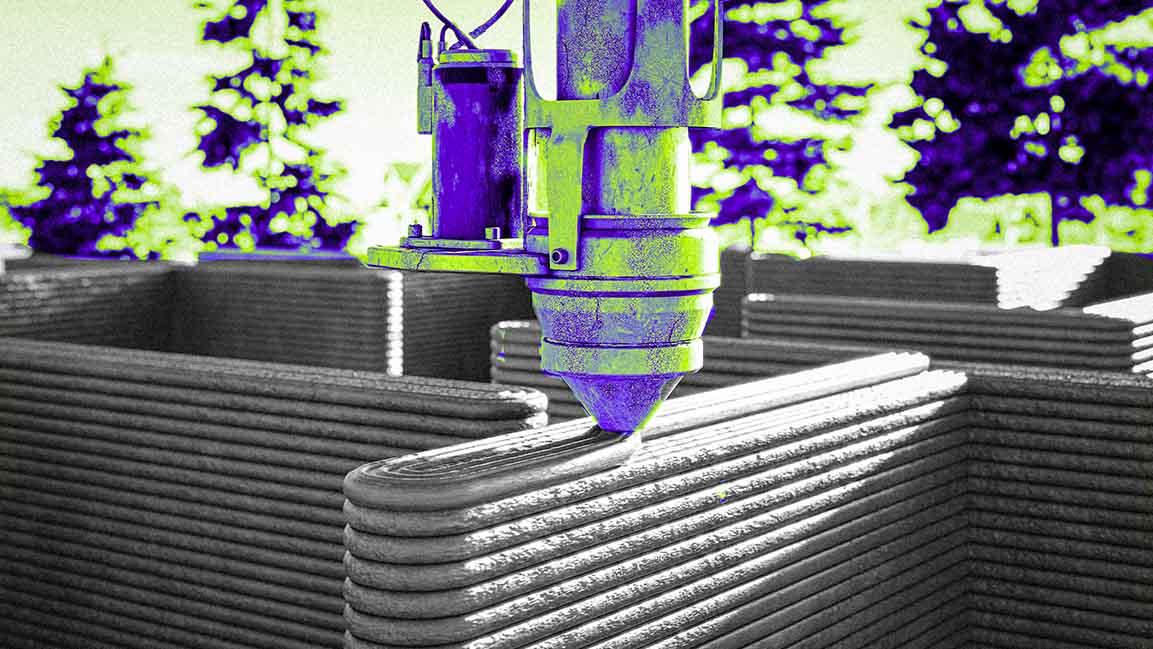

In a significant step for digital construction, UCC Holding, in partnership with the Public Works Authority (Ashghal), has started the printing phase of the 3D Printed Schools Project, which is set to become the largest construction development to date using 3D printing technology.

The project includes the construction of 14 public schools, two of which are being built using 3D printing. Each 3D-printed school will cover 20,000 square meters, for a combined total of 40,000 square meters, making the development 40 times larger than any existing 3D-printed building worldwide. These two-storey schools are designed on 100-by-100-meter plots, offering a new model for educational infrastructure in Qatar.

To achieve this scale, UCC Holding partnered with COBOD, a Denmark-based company specializing in 3D construction printing, to supply two custom-built BODXL printers. Each printer measures 50 meters long, 30 meters wide, and 15 meters high, roughly the size of a Boeing 737 hangar, making them the largest construction printers in operation today.

Printing began following extensive groundwork, including site development, equipment assembly, and testing. A specialized team of architects, civil engineers, material scientists, and printer technicians led the preparations. Over eight months, the team carried out more than 100 full-scale test prints using a BOD2 printer at a trial site in Doha. These trials helped develop climate-optimized concrete mixes and a custom nozzle to ensure accurate, smooth material extrusion.

In May, the team completed intensive training with COBOD engineers, covering everything from printer operations to quality control. According to the team, this marks a significant step in building local expertise in advanced construction technology and positions Qatar as a regional center for innovation and engineering.

Compared to traditional methods, 3D printing offers key advantages: reduced material waste, lower carbon emissions, faster timelines, and fewer transport requirements. Nighttime operations help avoid high daytime temperatures, improving concrete performance and reducing dust and noise.

Inspired by Qatar’s desert landscapes, the school buildings will feature curved, dune-like designs made possible by the geometric flexibility of 3D printing. Completion is expected by the end of 2025, highlighting Qatar’s growing focus on sustainable and innovative infrastructure.