- | 1:00 pm

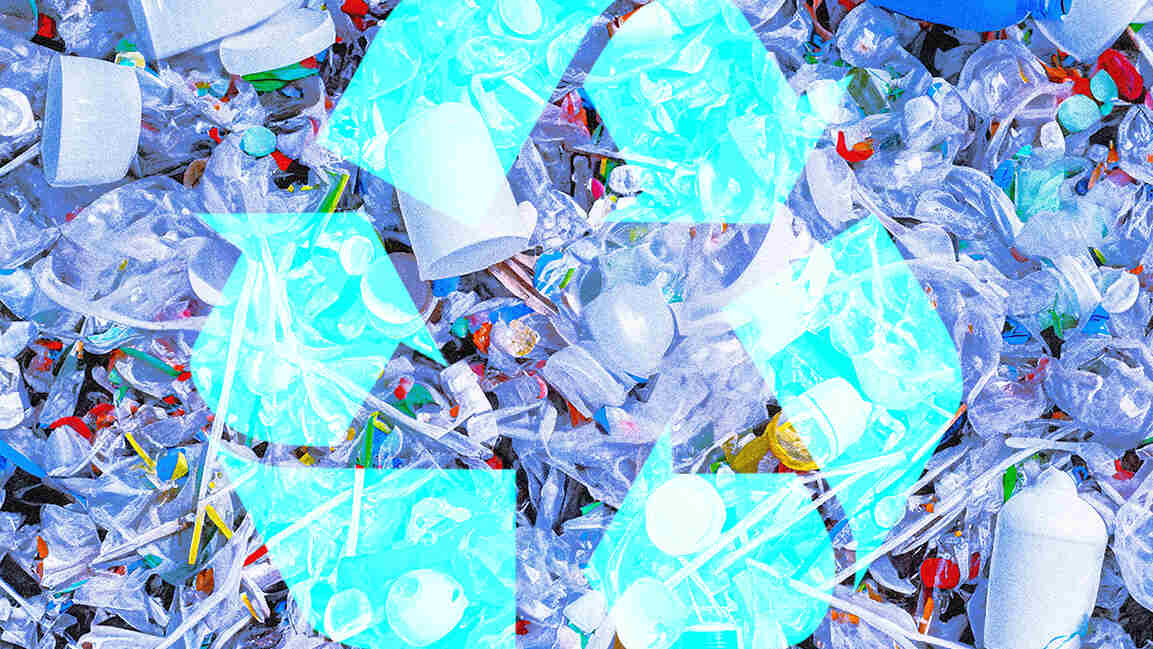

GCC must invest $12–25 billion to become global hub for circular plastics

The report highlights the region’s potential to ease a global plastics shortage, with demand set to exceed supply by 35 million tons by 2030.

The Gulf Cooperation Council (GCC) will need to invest between $12 billion and $25 billion in recycling infrastructure by 2045 to establish itself as a global hub for circular plastics, according to a joint report by the King Abdullah Petroleum Studies and Research Center (KAPSARC) and Strategy& Middle East, part of the PwC network.

The study underscores the region’s potential to help close the global shortfall in recycled plastics, with demand projected to exceed supply by up to 35 million tons by 2030.

Demand for recycled plastics is growing at 8% annually—far outpacing the 2% growth rate for virgin plastics—yet less than 70% of this demand is currently being met.

The GCC generates approximately 10 million tons of plastic waste each year, but only 10% is recycled, reused, or recovered. This aligns with the global average but falls behind leaders such as China and OECD countries.

In Saudi Arabia, where plastics and chemicals contribute 6–9% of GDP, the sector’s scale underscores both its economic significance and the opportunity for the region to advance circular solutions.

“With global mechanical recycling still under 10% and pressure mounting from ESG mandates, carbon regulations, and shifting consumer preferences, there is a growing mismatch between supply and demand,” said Devesh Katiyar, Partner at Strategy& Middle East. “The GCC is uniquely positioned to bridge this gap by leveraging its petrochemical strengths for circular solutions.”

Chemical recycling technologies, such as pyrolysis, are gaining traction globally, though their viability depends on feedstock supply, energy costs, and plant efficiency.

Modeling by KAPSARC and Strategy& suggests that GCC plants integrated into petrochemical clusters could break even at feedstock prices of $240–$280 per ton and remain profitable even at $450–$500 per ton, provided recycled plastics maintain a premium over virgin materials.

“The economics of chemical recycling are compelling for the GCC, especially when integrated into existing systems and supported by the region’s competitive energy costs,” said Jayanth Mantri, Principal at Strategy& Middle East. “Unlike traditional petrochemicals, chemical recycling is knowledge-intensive and offers potentially higher economic multipliers and innovation-driven growth.”

The report notes that scaling circular plastics will require progress in three key areas: securing reliable feedstock, establishing supportive regulations, and fostering innovation and consumer awareness. To ensure supply and market access, the GCC will need to develop plastic waste trade corridors with Asia, Africa, and Europe, supported by upgraded ports, customs systems, and traceability infrastructure.

Domestically, reforms such as extended producer responsibility schemes, recycled content mandates, and harmonized quality standards will be essential. Investment in chemical recycling, smart sorting, and blockchain traceability tools will also be needed, with public co-funding and consumer incentives helping to drive adoption.

The report further recommends blended financing to support a modern circular plastics ecosystem, with GCC countries leveraging sovereign wealth funds, public-private partnerships, and de-risking tools to attract international investment.