- | 9:00 am

AI can’t do what an architect does (yet!), but it’s already reshaping buildings

A Michigan elementary school just used AI to design its electrical system. It’s only the beginning of automating architecture.

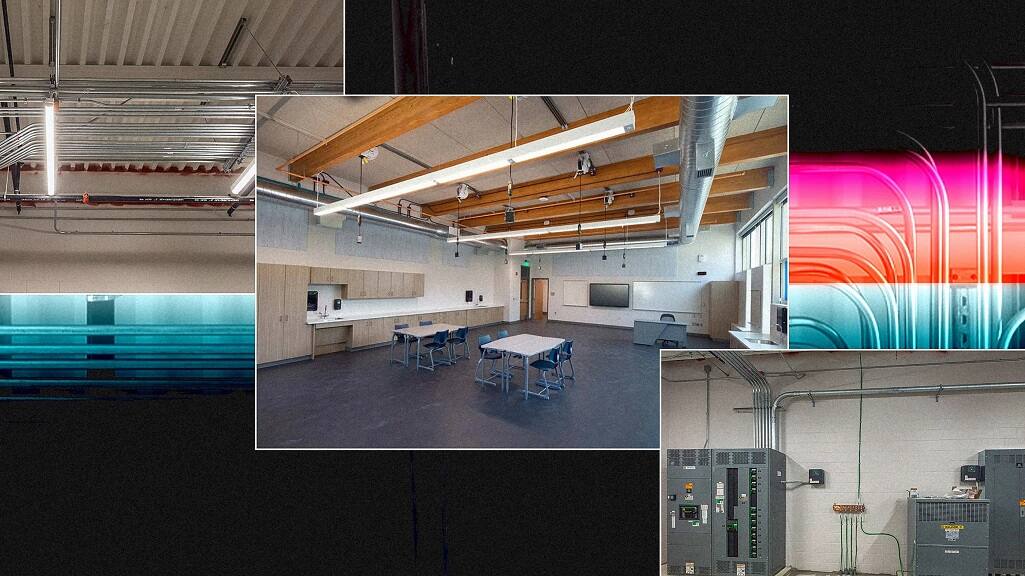

To understand how artificial intelligence is starting to shape the built environment, look at the ceiling inside Mt. Hope Elementary School in Lansing, Michigan. There, running across the tops of classrooms and hallways are thousands of feet of exposed metal electrical conduit—the tubing that holds the electrical guts of the building.

This tubing runs through the entire school, bringing power exactly where it’s needed. And for the first time in the U.S., this electrical system was designed completely by AI.

The AI company Augmenta created the tool that designed the electrical system. It uses a combination of machine learning and a deep background in electrical engineering to streamline the process of wiring up buildings.

Augmenta cofounder and CEO Francesco Iorio says that in the growing sea of AI design tools being applied to architecture and construction, few are focusing so specifically on the complex inner workings of buildings. “It is not new that people use generative and artificial intelligence technologies for simple things like floor planning, making sure that the facade looks good, or for shape exploration, massing, and that sort of stuff,” he says. “This is the very first time artificial intelligence designed a piece of critical infrastructure.”

Why AI-designed electrical systems make sense

Iorio says AI is an ideal tool to address the haphazard nature of designing electrical systems for buildings. Despite their essential role in making buildings work, electrical systems are often among the last parts of a building to get a detailed design.

“Mechanical systems and plumbing systems generally take priority in terms of the space inside buildings,” Iorio says. “Electricians are actually left to last, and essentially have to just figure it out and fit everything they need to fit inside the building.”

Augmenta’s generative design tool analyzes the design of the entire building, from its architecture to its mechanical and plumbing systems, and uses those parameters to formulate a more detailed design for the electrical system that complies with building codes. Instead of electricians coming to a building site after the plumbing and mechanical systems have been installed, Augmenta allows the electrical system to be formulated alongside those parts of the building that usually get constructed first.

More speed, less waste

The tool adds a level of precision to the material side of this work that speeds up construction. With highly detailed measurements of conduit lines, bends in those tubes, and connection points to outlets and breaker boxes throughout the building, Augmenta’s electrical system design can plug directly into automated tools that cut and bend conduit to exact specifications.

Iorio says the design of the Mt. Hope Elementary electrical system took only about two-thirds of the time it would have taken to design manually, and also reduced material waste by 15%. “There are really multifaceted advantages that this technology brings to the industry overall. This is just the tip of the iceberg,” he says.

Augmenta’s tools are being used to design electrical systems for other large-scale and commercial projects, from hospitals to data centers to manufacturing facilities, but Mt. Hope Elementary is the first project to actually come to completion. “For us, it’s very heartwarming that the first project is a school,” Iorio says.

The school has used the electrical system to do more than just keep the lights on. The design called for parts of the electrical conduit and other building systems to remain uncovered by drywall and visible within classrooms. “They are using the systems as a teaching tool,” Iorio says. “It’s showing the kids that this is how a building works.”