- | 8:00 am

How NASA’s X-59 recycled decades-old plane parts to make silent supersonic flight possible

The new supersonic plane breaks the mold with a radical new shape and digital cockpit, but it relies on ancient parts to make it all happen.

NASA’s X-59 Quesst experimental aircraft has taken a major leap forward, firing up its engine for the first time. This marks a crucial and final milestone as the team prepares the first runway and flight tests that will lead to a long series of trials that aim to prove what computational simulations have already proven: that supersonic flight can happen without the deafening sonic boom that marred and eventually grounded aircrafts like the Concorde.

The X-59’s goal—to transform that sonic explosion into a gentle thump—is an engineering challenge that its makers are addressing through a design that mixes a couple of radically new technologies with a lot of decades-old, battle-proven aircraft parts ingeniously repurposed to make it all work.

The engine run began on October 30, 2024, at the Lockheed Martin’s Skunk Works facility in Palmdale, California. The tests verified that all systems of the aircraft were functioning together properly, powered by the aircraft’s own engine rather than external sources used in previous evaluations. Jay Brandon, chief engineer for the X-59 at NASA, called the first engine run a “warmup” to make sure everything looked good before fully running the engine. “We then moved to the actual first engine start, which took the engine out of the preservation mode it had been in since installation,” Brandon explains in NASA’s press release.

Lockheed Martin’s Skunk Works design team, which is responsible for iconic secret planes from the old P-38 Lightning from Second World War to the SR-71 Blackbird, designed the X-59 in collaboration with NASA. From the start, the team knew that this plane couldn’t afford to totally reinvent the wheel with new advanced technologies. There just was no money for that.

With a $247.5 million budget—low for a cutting-edge, one-of-a-kind prototype like this—much of its feasibility had to rely on recycling decades-old components, keeping costs manageable and taking advantage of tried-and-tested hardware. “We weren’t trying to push the limits in any other way except to prove you could dampen the sonic boom,” Dave Richardson, program director for the X-59 at Lockheed Martin, told me last year during a video interview. “There is no radical technology in the airplane itself. It really is just the shape of the aircraft.”

New skin, old guts

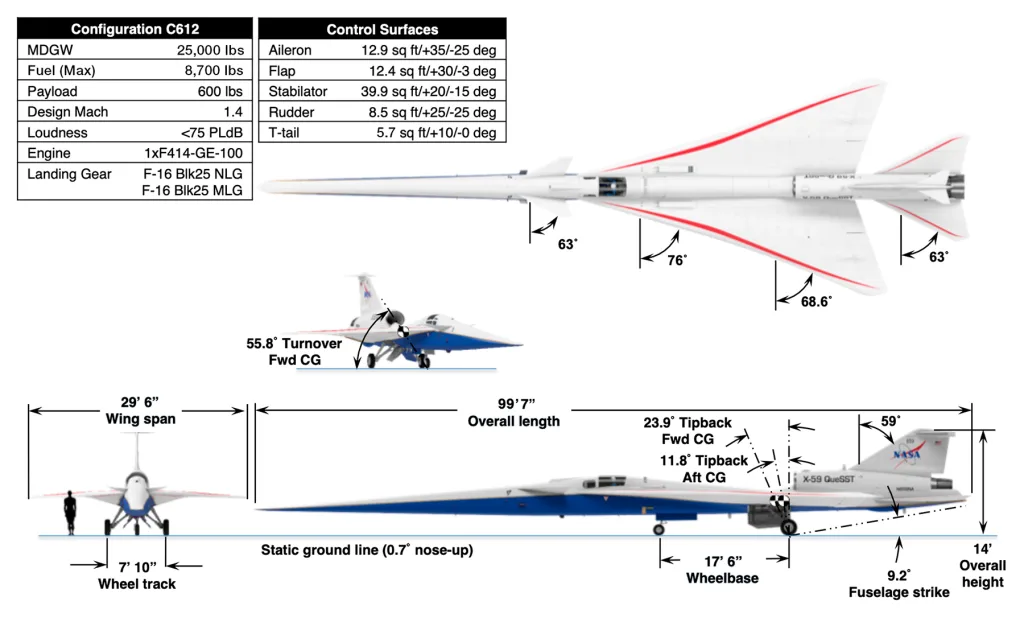

The X-59’s engine is a prime example of the team’s approach to mixing old and new. The General Electric F414-GE-100 inside the X-59 is the same power plant used in the U.S. Navy’s F/A-18 Super Hornet fighter jet. Providing 22,000 pounds of thrust, this engine allows the X-59 to cruise at Mach 1.4—roughly 925 mph—at 55,000 feet. The engine has already logged countless flight hours under demanding conditions, which translates into reliability for the X-59’s ambitious test flights.

By repurposing the F414-GE-100 engine and many other key components “stolen” from other airplanes, the team not only cut down on development time but also kept the typical budget overruns that plague these kinds of projects at bay. Using well-tested parts that have logged millions of hours of flight not only avoids testing new parts but also drastically reduce the risk of failure, as these components have already proven their reliability under a wide range of operational stresses. This approach also decreases the overall complexity of the design and reduces the number of potential breaking points, ultimately improving the overall safety and efficiency of the X-59.

The landing gear of NASA’s X-59 is sourced from the F-16 Fighting Falcon. Like the F-18 for the Navy, this has been the main battle horse for the US Air Force and many other air forces around the world for decades. The landing gear was chosen not only because it is made by Lockheed Martin—the parent company of Skunk Works—but also because its robust design is specifically suited for handling the stresses of military operations. Designed to withstand repeated, high-impact landings on shorter runways, the designers thought it would be the ideal choice for the X-59’s profile, making it an optimal choice for this experimental aircraft.

The propulsion system also incorporates the engine inlet from the U-2 spy plane, another legendary plane designed by the Skunk Works team. The U-2, renowned for its high-altitude reconnaissance missions, has a well-proven design that effectively manages airflow at extreme altitudes, where the atmosphere is much thinner than what you find in the typical cruising altitude of a regular jet. Integrating this part into the X-59 allowed engineers to ensure efficient engine performance without having to create a completely new inlet system. And once again, shaving a lot of dollars from the overall budget. The U-2’s engine inlet is engineered to fly at 70,000 feet, a capability that directly aligns with the X-59’s need for efficient high-altitude flight. Its integration ensures stable airflow to the engine, crucial for maintaining the consistent power needed for supersonic speeds.

The canopy of the X-59 is taken from the Northrop T-38 trainer aircraft, which has been used for decades to train pilots. NASA’s new silent supersonic aircraft doesn’t have a front cockpit, instead relying on a digital cockpit that uses displays and cameras, which is also the only new tech in the plane after its weird dart-looking shape. But it does have a canopy over the pilot’s seat. The T-38 canopy is designed to offer good visibility and withstand high-speed airflow, which makes it an effective solution for the X-59’s needs. This design ensures the pilot has an unobstructed view while also benefiting from a proven aerodynamic shape that integrates seamlessly with the aircraft’s long fuselage.

The control stick and rudder pedals are taken from the famous F-117 stealth fighter that came into the public eye during the first Gulf War. Known for its uniquely hard-to-handle flight characteristics, a byproduct of its triangular polygonal fuselage and wings, the F-117’s control system has proven its effectiveness in high-stress environments. By reusing these, the engineers ensured that the X-59 would benefit from a reliable and well-understood pilot interface. The familiarity of these old control systems, especially in an airplane that may be as difficult to handle as the X-59, contributes to the overall dependability of a new airplane because the pilots will have an easier time adjusting to the feeling and handling of this supersonic beast.

Start your engines

There are many other minor reused parts that neither NASA nor Lockheed Martin have disclosed, but all of them played a critical role in staying within the limited budget. They played the role of pre-made Lego blocks that needed to be seamlessly inserted into the X-59’s wild form.

The legendary advanced aerospace design group began working on what would eventually become the X-59 back in 2013. Early iterations focused on balancing the aircraft’s weight distribution to optimize supersonic performance. “The heavy parts of the plane needed to be as far back as possible. We put nothing out in the front,” Richardson explained to me during our interview. This approach resulted in the plane’s strikingly long nose and sleek design, carefully tailored to manage shockwaves as they travel along the body of the aircraft.

With this engine test and a first flight expected early next year, the X-59 Quesst mission is poised to tackle one of aviation’s biggest challenges: making supersonic flight over land feasible again. Its success could pave the way for a new generation of commercial airliners that travel faster than sound without disturbing those below. This kind of leap is even more interesting when you consider how the genius designers used off-the-shelf parts wherever possible, managing to create an experimental aircraft that leverages the reliability of familiar systems while still pushing the boundaries of aerodynamics and noise reduction.

“We have a small step that could lead to a big transformation in air transport,” Richardson told me. After the aircraft takes off and the pilots assess that it’s fully ready to begin work, the real tests will start and the plane will be flying for months over various U.S. communities while ground teams measure both the physical sound of the reduced sonic thump and the public’s reaction to it.

After their study is complete, they will provide data for regulatory bodies in order for them to amend flight laws in the United States and around the world, effectively lifting the current ban on commercial supersonic flights over land. As Paul Dees, deputy propulsion lead for the X-59 at NASA, says in the NASA press release announcing the milestone: “The success of these runs is just the first note of a symphony; we still have many notes to play until the flight.” Hopefully, a symphony that will end in thundering fanfare to celebrate the beginning of a new commercial silent supersonic flight era as well.