- | 9:00 am

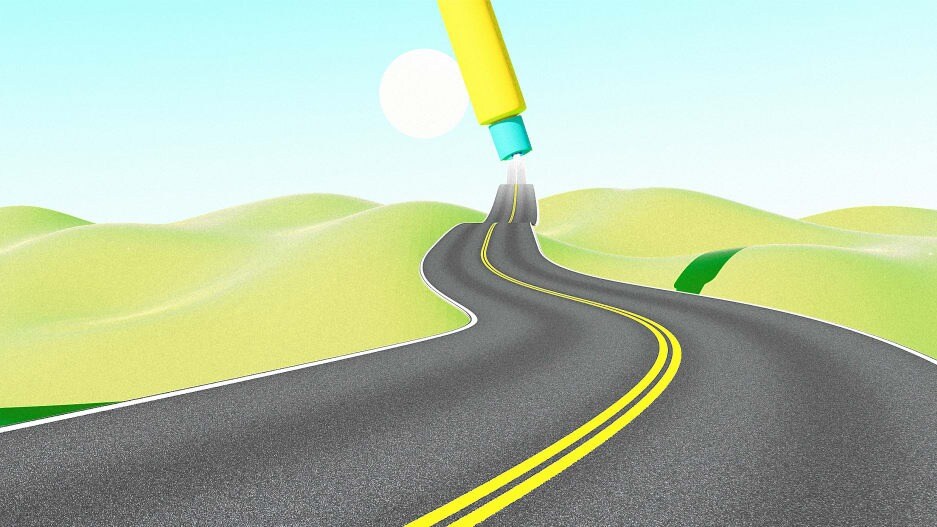

Roads need sunscreen too: Adding old tires to roads could help them last twice as long

A team of engineers found that adding crumb rubber from old tires can protect roads from damaging UV rays.

Roads suffer through a lot. Heavy trucks roll, spin, and brake on them; rain seeps through; and the sun beats down. As a result, they swell, sink, and crack; then the cracks fill up with snow and ice, which widens them even further. Much of that happens because typical roads are made of rock and salt aggregates, which don’t bond well with asphalt and end up disintegrating under all that pressure. But changing up the recipe can help.

In a new study, a team of engineers at Australia’s RMIT University has found that a specific amount of crumb rubber, made from old tires that get ground up into a fine powder, can act as a sunscreen for roads. This both helps the roads to last longer and prevents old tires from being sent to a landfill.

Crumb rubber is already used in many roads, but until now researchers have been testing only how it can protect roads against heat and moisture. This study suggests that UV radiation may have an equally big impact, providing yet another reason to use rubber in asphalt.

In the U.S., so-called rubberized asphalt dates back to the 1960s, when materials engineer Charles McDonald started sealing cracks with shredded tire rubber. Most of the National Highway System had already been built by then, but roads need repaving every 10 to 20 years, and many states, including Arizona, California, Florida, Washington, and Texas, have since experimented with rubber-loaded pavement.

The benefits are extensive: Rubber can help make asphalt roads less brittle in the winter and stiffer in the summer; it can make them safer by reducing skidding and increasing traction; and it can dampen the sound of highways, negating the need for sound barriers. (Roads around Phoenix have even been touted as “quiet roads” with a decibel level that’s 12% lower than conventional roads.)

Using rubber also gives old tires a new lease on life. Australia produces almost 460,000 tons of waste tires a year, causing “mountains of tires” as Filippo Giustozzi, an associate professor at RMIT and the lead author of the study, calls it. Giustozzi says that Australia recycles 70% of used tires, but 30%—150,000 tons—still end up in the landfill. This is especially true for mining tires, which are larger and harder to recycle because transporting them from remote mining sites can be expensive.

What makes tires particularly good contenders for strengthening roads is something called carbon black, a type of filler that’s added to make tires more resistant to UV radiation. As a result, the team had a hunch that carbon black could help rubberized roads resist UV light. But the idea had to be tested.

Researchers put four different asphalt samples (one without rubber and three others with different concentrations of rubber) into a UV light machine. The samples remained there for a little over a month (equivalent to the amount of sun that local roads around Melbourne are exposed to for a whole year). Then the team conducted performance tests, including using a special machine (which also measures the level of viscosity in ketchup and toothpaste) to see if the resulting asphalt was the right consistency to be used on roads.

In the end, the samples with the highest concentration of rubber, or 22.5% of the total asphalt mass, came out with half as much damage as the rubber-free sample. (Roads in Arizona have a similar concentration of rubber.) Giustozzi notes that anything over that ratio would likely compromise the durability of the asphalt and make it hard for machines to produce.

The experiment was done in a lab, but Giustozzi’s team is now working with a dozen local councils around Sydney. They’ll begin trialing various recipes in the fall, and monitor them for about two years. Then, finally, the rubber will meet the road.