- | 8:00 am

Scientists literally reinvented the wheel with this new shape-shifting, all-terrain wheel design

Inspired by how liquid droplets work, this new wheel can morph from hard and circular to squishy, depending on the terrain.

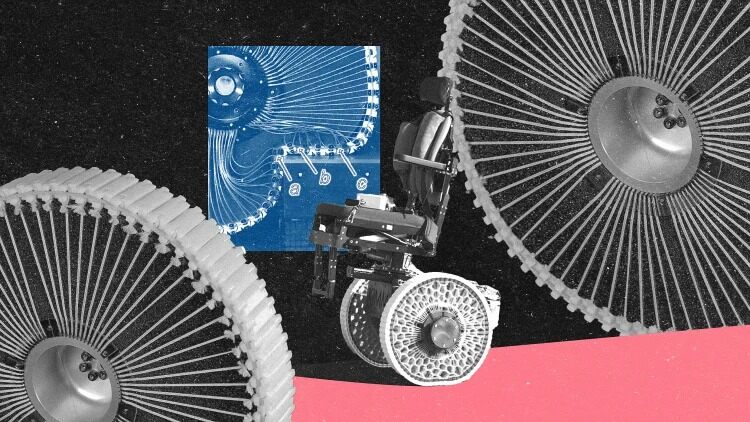

For most people, “reinventing the wheel” is a silly idiom. For a team of South Korean scientists, it is their job. According to a new peer-reviewed research paper from the journal Science Robotics, the classic rubber circle could someday be a thing of the past. Scientists are experimenting with a new shape-shifting device that’s capable of being as hard—and fast—as regular tires, or as malleable as liquid metal, depending on the terrain they are traversing.

These new wheels can change shape in real time to roll over rough terrains; they can, in theory, overcome hurdles of almost any shape. The wheel’s inventors believe the design could change the way we build wheelchairs, robots, and any other movable vehicle, extending a machine’s capabilities far beyond what’s currently possible.

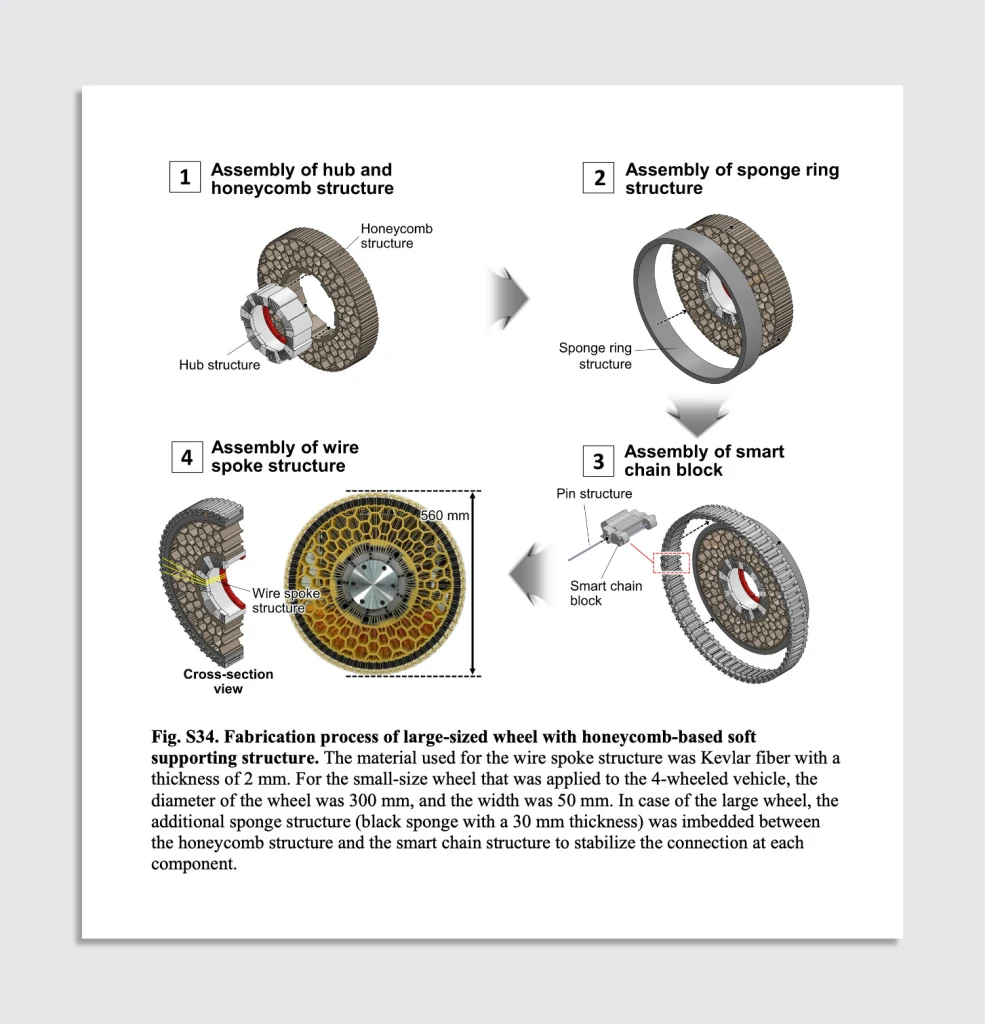

To do this, the engineers created something they call “smart chain structure.” Located around the outermost part of the wheel, this structure consists of a series of interconnected blocks that resemble the links of a chain. These blocks are connected to the central hub of the wheel by wire spokes.

According to the paper, the wheel’s ability to change shape hinges on the adjustment of the tension in the wire spokes. That tension is controlled by altering the gap between the two sides of the central hub. When the hub-gap distance is increased, the spokes pull the chain blocks inward, tightening the structure and causing the wheel to assume a rigid, circular form. This state is optimal for fast movement on smooth, flat surfaces.

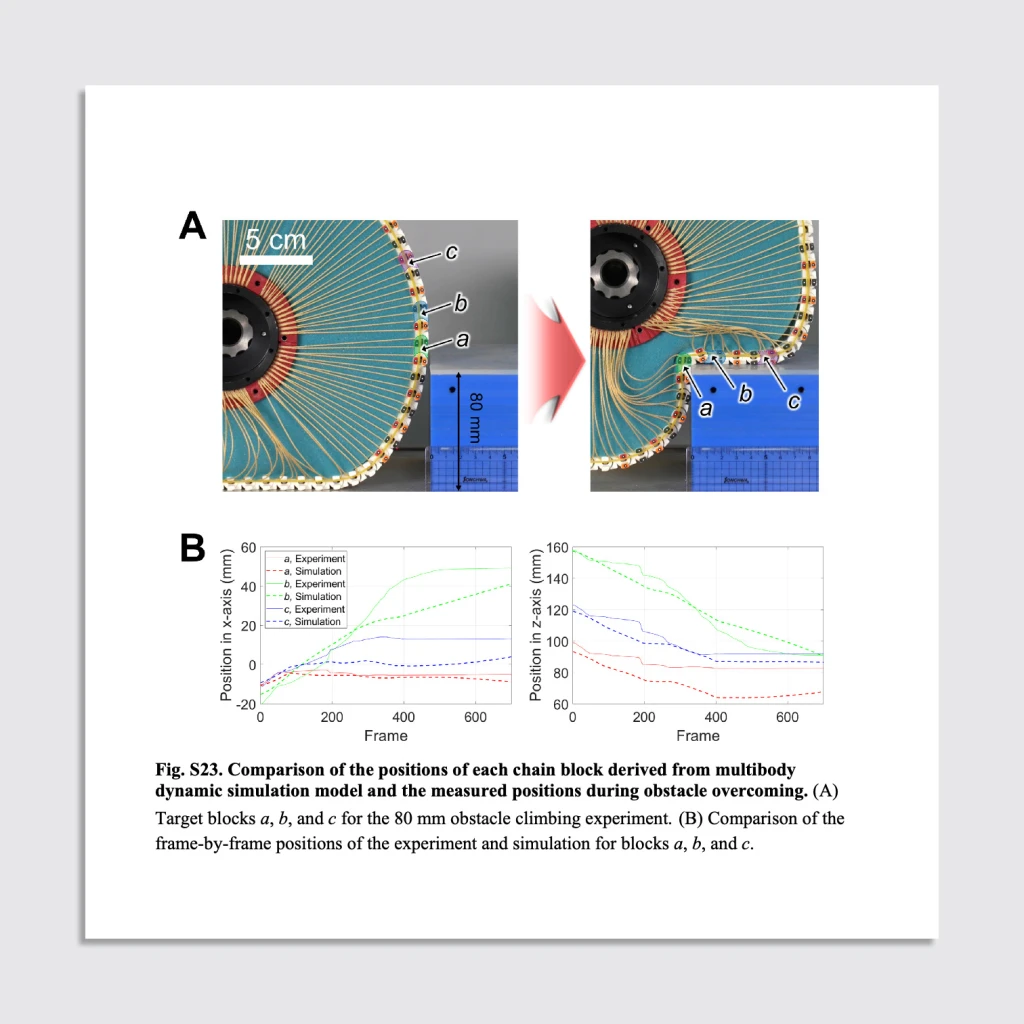

Then, when the hub-gap distance is reduced, the tension in the spokes decreases, allowing the chain blocks to spread outward. This reduction in tension causes the wheel to become more flexible and pliable. In this softened state, the wheel can deform, adjusting to the shape of the terrain it encounters and enabling it to overcome obstacles that are up to 40% of its radius.

Why all-terrain wheels are a major design challenge

Despite their foundational role in civilization, wheels have stayed more or less the same for millennia. But traditional wheels have severe limitations when it comes to traversing uneven or obstacle-filled ground. Numerous attempts have been made to improve this, with varying levels of success.

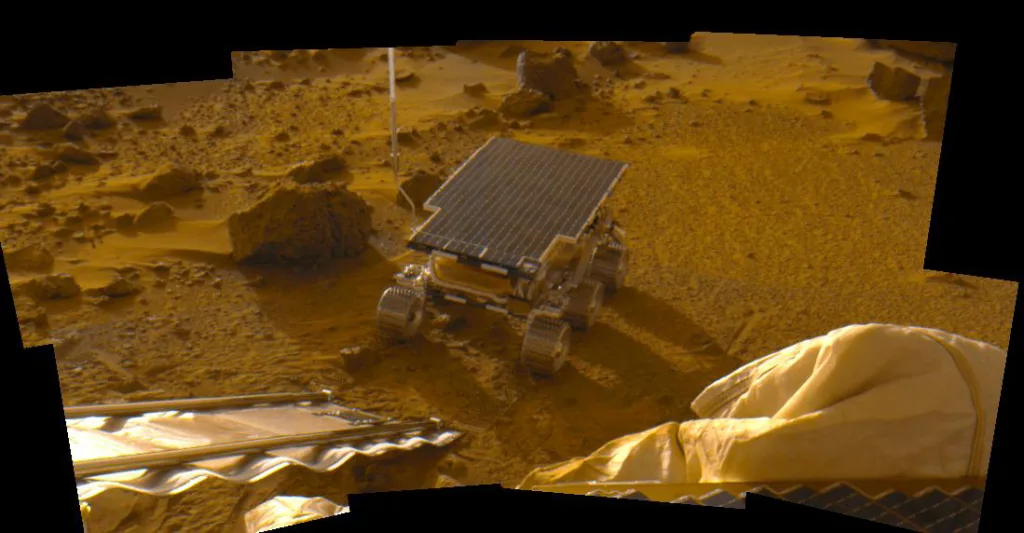

NASA is perhaps the most advanced garage when it comes to developing all-terrain vehicles. The Mars rover Sojourner—which started rolling over the Ares Vallis channel on July 4, 1997—was the first wheeled vehicle to traverse another planet. To be able to handle the Red Planet’s rough terrain, it featured six 5.1-inch wheels made of aluminum mounted on a frame that had two elements: a “Bogie” connected the front wheel with the central one; a “Rocker” connected the rear wheel with the first element.

This allowed the wheels to move up and down so they could always remain on the ground, theoretically overcoming obstacles as high as 7.9 inches. That design evolved in subsequent rovers, achieving the best design in the Mars Curiosity and Perseverance rovers, the near-twin Volkswagen Beetle-size robots equipped with six nickel-titanium alloy tires.

Those wheels, however, were hard and suitable only for heavy-duty, slow Martian work. The possibility of using the same technology on Earth would be prohibitively expensive, both for production and maintenance. Plus, it’s too unwieldy to be used in devices like wheelchairs.

In 2021, South Korean tire company Hankook developed a new generation of origami-inspired transforming wheels that aimed to solve this challenge. These were too complex and delicate to become a reality, however, requiring an active electrical mechanism that introduced multiple points of failure.

Inspired by nature

Scientists modeled the new wheel after how surface molecules, like water, experience forces. Just as surface tension pulls a droplet into a rounded shape by contracting its surface molecules inward, the tension in the wheel’s spokes pulls the blocks into a circular configuration. When the tension is relaxed, the structure becomes more pliable, much like how a droplet can deform under external forces.

According to the research paper’s data, this variable-stiffness mechanism has been successfully tested in practical applications, including a two-wheeled wheelchair and a four-wheeled vehicle. These tests demonstrate that the wheel can transition between rigid and flexible states in real time, allowing the vehicles to traverse both smooth surfaces and uneven terrains with obstacles that are as tall as 1.2 times the wheels’ radius, including everything from rocks to steps.

While the paper claims that the wheel morphs in real time, this seems to refer to the wheel’s ability to switch between states quickly and effectively as the terrain changes. It does not explicitly mention whether this adjustment is automated through sensors or manually controlled by an operator. But given its mechanical nature, it’s logical to assume that a final product would be equipped with pressure sensors that would automatically sense the change in terrain and adjust the spoke tension accordingly.

The ability to dynamically adjust to terrain could offer a significant advantage for devices that operate in challenging environments. First, it’s simpler, requiring fewer mechanical elements than previous designs like those used by NASA’s Curiosity and Perseverance rovers on Mars. In theory, this should make the new wheel less prone to breaking than previous all-terrain vehicle designs. That is, once they solve for the wheel’s main drawback.

The current wheel design tends to get pieces of dirt in between the crevices of its radius. Over time, the dirt makes the mechanism fail. The inventors say, however, that they can solve this with flexible covers that will hide the exposed empty spaces in the current design. Once they solve for this issue, it seems the researchers may have found the holy grail of all-terrain wheels.