- | 8:30 am

Solid-state batteries could be key for EVs—and they’re making a leap toward mass production

Solid-state batteries are capable of holding much more energy per unit of mass than today’s lithium-ion batteries, which means an EV could go for much longer before needing to be recharged.

This piece originally appeared on Inside Climate News. It is republished with permission. Sign up for their newsletter here.

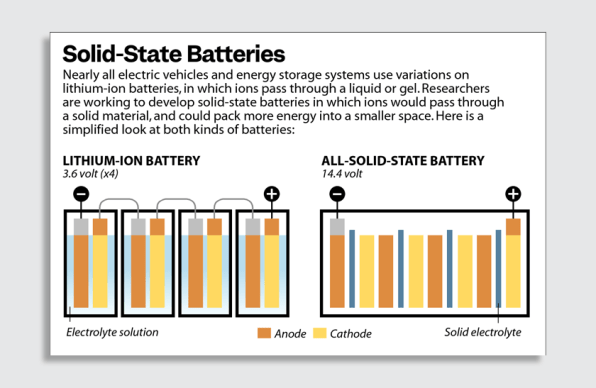

At some point, the development of solid-state batteries—in which electrons flow through a solid material instead of a liquid or gel—is going to lead to electric vehicles that can go much farther on a charge and battery-storage systems that can hold more energy while taking up less space. We just don’t know when that is going to be.

But in the last 10 days, two announcements offer reasons to think the answer is “sooner rather than later.”

First, Solid Power, a Colorado-based company developing solid-state EV batteries for partners including Ford and BMW, said it has completed installation of a “pilot production line” that is capable of making about 300 battery cells per week. This signals that the technology is now moving from the lab to the factory.

Second, University of Houston researchers published a paper showing how they have developed a glasslike material that is highly effective as an electrolyte—the part of a battery that electrons pass through during cycles of charging and discharging—for use in a sodium-sulfur battery for energy storage. The research is notable because this is a solid-state battery, and because it shows the promise of sodium-sulfur batteries as an alternative to lithium-ion batteries for long-duration energy storage.

Let’s step back for some solid-state battery 101. I reached out to George Crabtree, director of the Joint Center for Energy Storage Research, which is based at Argonne National Laboratory near Chicago, to help explain why these batteries are special.

“I would say, first of all, that solid-state batteries are very likely to be the next big thing at the commercial level,” he said.

They would be the biggest step forward in battery technology since 1991, he said. That was when Sony released the first commercial lithium-ion battery.

Solid-state batteries are capable of holding much more energy per unit of mass than today’s lithium-ion batteries, which means an EV could go for much longer before needing to be recharged, he said. Even though the electrolyte is solid, it is porous on a microscopic level, allowing electrons to pass through it.

Researchers have long known that a solid-state design has advantages over batteries that use a liquid or gel, including lithium-ion batteries. One of the big advantages is that solid electrolytes can be made to weigh less and take up less space than liquids or gels. But there are some big engineering challenges that have slowed this technology from reaching consumers.

One issue is dendrites, the spiky fibers that can accumulate in a battery during recharging, diminishing the battery’s performance. Dendrites aren’t alive, even though they sometimes resemble branches of a tree, or even clumps of wild mushrooms. They are a problem for many kinds of batteries, including lithium-ion, and have been especially vexing for researchers designing solid-state batteries. The new solid-state designs have a variety of approaches to dealing with the problem, including the use of an electrolyte that resists or otherwise limits the growth of dendrites. Researchers have developed solid electrolytes made of ceramics, glass and mixes of ceramics and glass.

Solid Power, based in Louisville, Colorado, is a spinoff from research begun at the University of Colorado Boulder. It was founded in 2011 and is now publicly traded with a market capitalization of $1.3 billion. The company’s battery uses a ceramic-glass electrolyte.

With its partners Ford and BMW, Solid Power is one of the leading players in the race to develop a mass-market electric vehicle that runs on a solid-state battery system.

Among the major competitors is QuantumScape of San Jose, California, which has a market capitalization of $5.1 billion and is working with Volkswagen.

Just about every automaker is developing solid-state batteries, either with an external partner like Solid Power or QuantumScape, or through internal research and development.

By announcing its new production line, Solid Power is indicating that it is on track to produce its systems on a much larger scale by the mid-2020s.

“With the EV cell pilot line now installed, our next big challenge is commencing production at scale and building cells that meet the requirements necessary for us to enter into automotive qualification later this year,” Derek Johnson, chief operating officer at Solid Power, said in a statement.

He is referring to the years-long process of working with automakers to validate the safety and effectiveness of the systems before the batteries can be sold to the public.

In addition to improving the performance of EVs, solid-state batteries could be part of a new generation of energy-storage systems.

The University of Houston research results, published in the journal Nature Communications, show the results of a project to develop a solid-state battery for use in grid-scale energy storage.

Researchers say their battery is low cost, easy to build, has a high degree of mechanical stability and is chemically stable—four important factors for viability in the market.

“To date, no single sodium solid electrolyte has been able to achieve all four of these requirements at the same time,” Yan Yao, an electrical and computer engineering professor and co-author of the paper, said in a statement.

The key component is the glasslike electrolyte that uniquely combines the properties of oxygen and sulfur, Yao said in an email. It also resists dendrite formation.

His team is trying to develop a battery that has the potential to combine low costs and an ability to discharge for up to 12 hours on a single charge. The key to the low costs is that one of its main materials, sodium, is widely available and affordable, in contrast to lithium.

I asked Crabtree how these recent developments in research and manufacturing fit into the bigger picture of the transition to clean energy.

“Lithium-ion is the best battery we’ve ever had,” he said. “However, it can’t do everything.”

Lithium-ion batteries have been highly effective for the current generation of EVs but are not well-suited for long-haul ground vehicles, rail, ships or aircraft. Lithium-ion batteries also are not well-suited for grid-scale energy storage of more than four hours.

Much of current battery research is looking at what materials and designs are going to be most effective for these other applications, he said. The development of solid-state batteries is a small part of this larger picture.

So solid-state batteries can make EVs and energy storage systems capable of holding more energy than today’s batteries, but that’s just the beginning of something bigger and transformative for the energy economy.