- | 8:00 am

The problem with your cashmere sweater

Cashmere clothing is cheaper than it used to be, and that’s not a good thing.

If you buy a cashmere sweater from Johnstons of Elgin, a 226-year-old Scottish wool mill, you might pay $450. Some other brands charge thousands. But it’s also possible to buy a cashmere sweater elsewhere for $50 (or even less if it’s on sale).

Cheap cashmere has become ubiquitous—available at stores like H&M and Costco, in the form of turtlenecks and dresses and sweatpants and even underwear. Fast fashion democratized a product that used to be a luxury, but the quality, unsurprisingly, isn’t good. The price points are low enough that the clothing can seem semi-disposable: If a sweater almost immediately pills or develops a hole, you might just buy another. And as more and more cashmere clothing sells, it’s destroying the environment where the material is produced. That could eventually decimate the supply chain.

“If a brand’s selling a cashmere sweater for $60 or $70, something’s fundamentally wrong,” says Nick Keppel-Palmer, one of the founders of Good Growth, a company that’s trying to make the industry more sustainable. “Someone is losing out in that. And we’re all losing out in the end. Cashmere is way too cheap.”

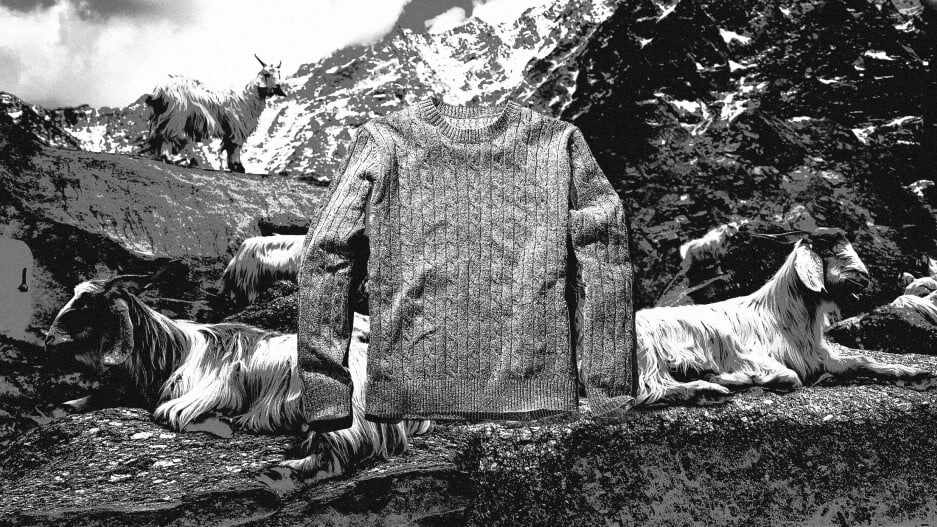

For centuries, cashmere was a luxury item because the material is hard to make. The process starts in remote areas like the Gobi Desert, where cashmere goats grow two layers of fleece to stay warm in bitterly cold winters. In the spring, herders comb the goats to harvest the fine, soft undercoat. (In a year, one goat might produce only enough cashmere for a single scarf.) The raw material then has to be cleaned and sorted, with the longest, finest hairs making material that’s stronger and longer-lasting. The way that the hairs are spun into yarn also affects whether the final piece of clothing could last for decades or start to lose its shape or texture after only a few wears.

In Mongolia, one of the world’s largest exporters of raw cashmere, the goat population used to be much smaller. When the country was part of the USSR, there were strict limits on how many goats each herder could have, for a reason: Because goats eat voraciously, and even eat the roots of plants, a large herd can quickly change the landscape so much that it can’t recover.

When the Soviet Union collapsed, herds quickly expanded. In part, that’s because the new economy meant that families needed to make more money, and producing more cashmere was the simplest way to do it. Some other types of jobs disappeared with the USSR, and more Mongolians turned to herding to make a living. (That hasn’t always worked out: One in four Mongolians now live in shantytowns outside the capital, and many are former herders.)

At the same time, as China embraced a market economy, it built up new processing facilities for cashmere, and started buying huge quantities of the raw material from Mongolia. “There was a whole wave of Chinese entrepreneurs who saw the opportunity, and they built huge yarn production operations in China,” says Tim Ewington, cofounder of Aethel, a British startup that makes high-quality cashmere clothing. In the past, most Mongolian cashmere had been sold to small, high-end mills in Europe, like the kind that Aethel still uses. But China became the biggest customer, often turning the material into lower-end clothing. The quality of the fiber itself has also declined as herders prioritize quantity over quality.

DEMAND FOR CASHMERE IS RUINING MONGOLIA’S GRASSLANDS

China expanded its own cashmere herds—causing more environmental stress in its own borders—and also stoked demand for much more cashmere production in Mongolia. There are now more than seven times more goats roaming Mongolia than there were in the 1980s, or an estimated 30 million animals in total. Along with other livestock, there are now perhaps twice as many animals as the land can support. Most of the country’s grasslands are now degraded and slowly turning into desert. Current production levels can’t be sustained over time. Climate change, with more extreme heat and drought, is exacerbating the challenge.

“Until the apparel industry gets its head around managing volumes to a level that is sustainable for natural environments, it’s going to get worse,” says Keppel-Palmer. Good Growth is now working with herders to help them find new income streams—including selling more wool from their sheep and more unusual fibers like horsehair combed from horses. That means that they can make more money with fewer goats. (Other animals, it’s worth noting, are less destructive when they graze.)

Some companies are also trying to help herders better manage the land. The luxury giant Kering worked with the Wildlife Conservation Society, NASA, and other partners to help herders recognize signs of overgrazing, and learn about other methods that could help them increase yield so they can have fewer goats. Naadam, a brand that launched after the founders happened to travel to Mongolia, buys directly from herders and has experimented with methods like fencing off some areas of grassland to help it regrow.

Good Growth recently started working with a group of herders to share maps, based on satellite data, that help them move to new grazing areas when one area is becoming overgrazed. “We basically use satellites to help them see what they can’t see because it’s outside of their immediate vicinity,” Keppel-Palmer says.

There’s much more that brands can do, he says. Most apparel companies still don’t know where their materials are coming from and don’t really understand the problems they’re causing. He argues that talking about location could be a marketing strategy. (Some companies are starting to take this tack, like Cuyana, which talks about its “single-origin” cashmere from a particular plateau in Inner Mongolia.)

Brands could adjust their deadlines to better support animals; right now, goats are sometimes sheared too early, putting them at risk in cold weather, to meet the demands of the market. “The seasons that apparel companies have are out of sync with natural seasons,” he says. “One of the things we’re trying to do is bring designers into the landscape so that they have a much better understanding of what you can do by working with the landscape.”

Having a minimum price for cashmere could also help herders move to smaller herds. “The cashmere market goes up and down, and went down a lot during COVID-19,” says Troy Sternberg, a researcher at Oxford University. “The herders’ approach is to have lots of animals as an insurance policy.” The government could also do more to move the industry in a more sustainable direction. Right now, incentives are aligned with higher quantities of cashmere, rather than higher quality.

RECYCLED CASHMERE IS GROWING

Several companies, like Reformation, are moving to recycled cashmere. Patagonia uses recycled cashmere blends in some products; the company says it doesn’t use new cashmere fiber because there isn’t yet a standard to ensure that animals are ethically treated. The recycled material faces some challenges. The current recycling process makes fibers shorter, so the cashmere has to be mixed with materials like wool to be stronger. And right now, if every brand wanted to use recycled cashmere, there wouldn’t be enough available. Re-Verso, a major Italian recycler, produces around 600 tons of the material a year; Mongolia alone exports more than 10 times as much cashmere. (Ralph Lauren recently began collecting old cashmere sweaters for recycling, from any brand, which may help efforts grow.)

Some companies have eschewed cashmere completely, partly because of an animal rights campaign from PETA. Others are working on alternatives, like the Japanese startup Spiber, which developed a cashmere-like material that’s grown in a bioreactor.

For brands that do still use new cashmere, it’s important to make products that last. “People buy far more clothes than they need,” Ewington says. “The first thing we do is try to make very nice sweaters that aren’t about fashion seasons. With big brands, their whole business model is built around volume.” The company also uses the highest-quality materials and manufacturing so the products can last for years.

For consumers, it’s hard to tell at a glance if a cashmere sweater has been well made. One processing technique, for example, can make the material look fluffy in a store, but weakens it so that it will fall apart more quickly. “It’s lovely for the first two or three wears, and then it’s probably going to have to go in the bin at that point,” Ewington says. Price isn’t always an indicator, since a relatively affordable sweater from Uniqlo might be well made and a luxury brand might not be. But in general, a more expensive product is likely to be better constructed, with better quality yarn.

Good quality cashmere should also be washable, Ewington says. “I’m suspicious of brands that say ‘dry clean only.’ It’s basically the hair of a goat, and goats get pretty wet. You should be able to wash any cashmere that’s of decent quality.”

If you can’t afford to splurge, try a thrift store: I found a decades-old cashmere sweater that still looks good now despite my frequent use. Meanwhile, the sweater that I bought on sale for $32 last fall got a hole after wearing it twice, and it’s now at the back of my closet.