- | 9:00 am

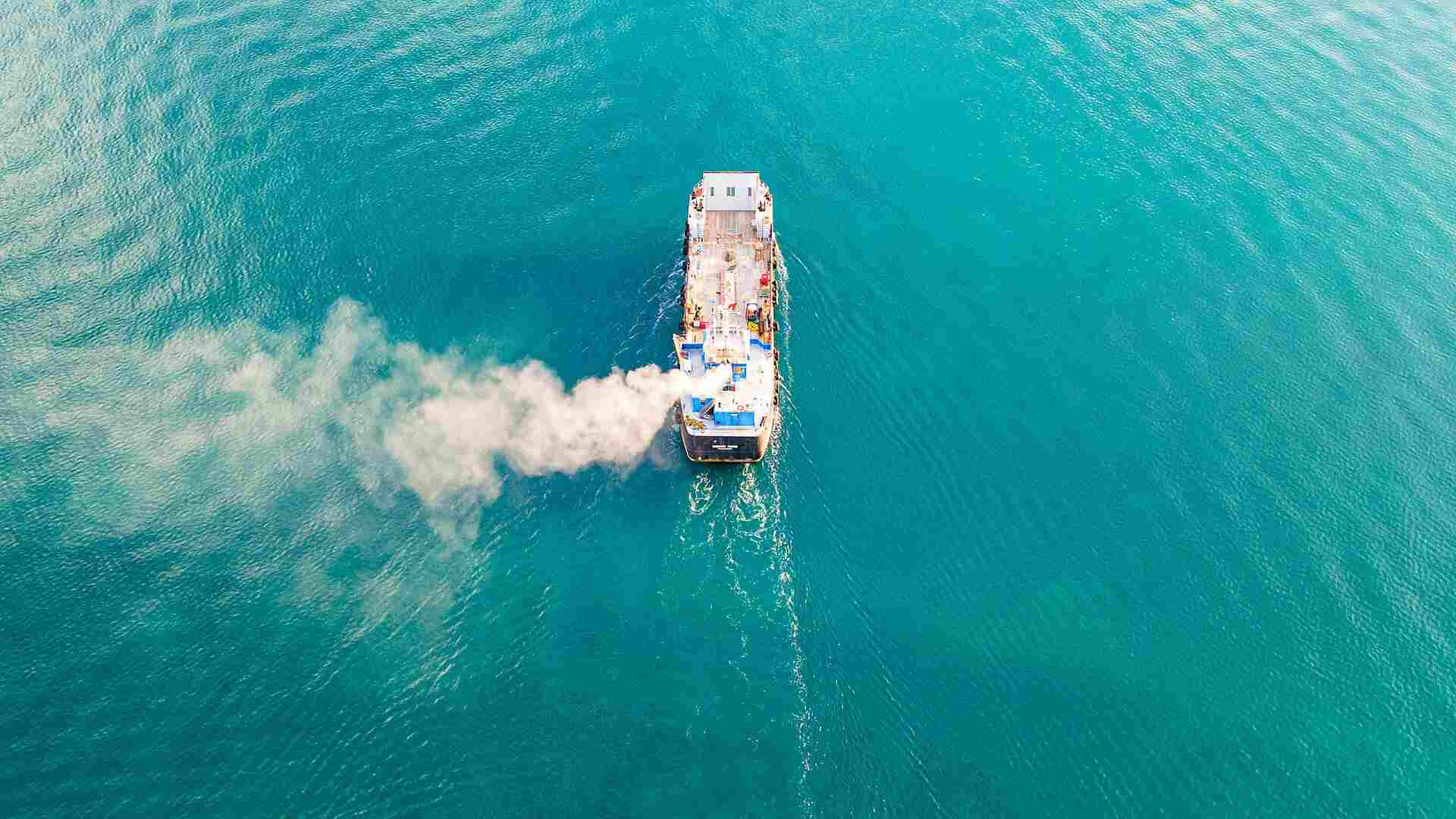

This tech turns cargo ship exhaust into safe ocean salts

A CalTech spinoff uses limestone to tackle carbon dioxide in shipping exhaust. The shipping company Lomar will soon begin testing the process.

The thousands of cargo ships that are used to deliver everything from your next pair of jeans to your car emit around a billion metric tons of CO2 each year. Cleaner shipping fuel and innovations like modern sails will take time to scale up. One startup is working on a solution that could tackle the problem faster. The company, called Calcarea, captures CO2 from a ship’s exhaust and converts it into salty water that can safely be returned to the ocean as the ship sails.

The technology, which spun out of research at CalTech, mimics a process that happens naturally. “This is the buffering reaction that the Earth has used for billions of years to deal with volcanic CO2 coming into the atmosphere,” says CalTech professor and Calcarea cofounder Jess Adkins.

Over tens of thousands of years, CO2 in the ocean reacts with limestone shells, turning the CO2 into calcium ions and bicarbonate. “It is exactly the same thing that happens in your stomach when you take a Tums,” Adkins says. “This is like the antacid for the ocean.” Adkins, a chemical oceanographer, had spent a decade studying the basic science of how the natural process works. Then he realized that it might be possible to make the same thing happen much faster in a reactor to help fight global warming.

On a ship, the system will start by using a “scrubber” to capture CO2 from the diesel exhaust in the smokestack. (This step works by flowing the gas through water, and it’s cheaper than technology that uses chemicals to capture CO2.) Then the CO2 goes into a reactor along with limestone and ocean water. “As the ship is moving through the water, it’s passing that water through our reactors, converting the CO2 into something that’s safe and permanent,” says Adkins. Though the tech takes up some room that could otherwise be used for cargo, the startup thinks that it will be the lowest-cost way for shipping companies to decarbonize.

Because the CO2 is converted to calcium and bicarbonate, there’s no chance that it can escape back into the atmosphere. The end product can be released into the ocean, so the ship doesn’t need extra space to store captured CO2 to deliver somewhere else. And because the process happens in a reactor, it’s possible to carefully track how much CO2 is converted. Around 90% of the CO2 can be removed from the ship’s exhaust. Only around half of that is converted to bicarbonate. The rest goes into the ocean as CO2, where most of it will likely eventually be converted through the natural process. The system also removes sulfur, another pollutant, at the same time (sulfur scrubbers already exist, but the new system releases water that’s much less acidic and has far lower concentrations of other contaminants.)

The startup has tested prototypes of the basic tech on land and proved that it works. Lomar, a shipping company, is now collaborating with Calcarea to further develop the system that will go on ships. Calcarea plans to test its latest prototype on one of Lomar’s ships later this year or in early 2025.

It’s not a replacement for alternatives that can avoid fossil fuels completely and eliminate other problems, like the carbon footprint of producing diesel. But the new technology is a low-cost way to make a major dent in emissions now.

“CO2 that we remove tomorrow is way more important than CO2 that we remove in 10 or 20 years,” says Adkins. “Getting the industry that emits a gigaton a year started on CO2 removal right now is way better for the climate than waiting for the alternative fuels to come out.”