- | 12:30 pm

Ferrari’s Elettrica could be a masterclass in how to engineer emotion from electrons

For Ferrari, going electric isn’t about compliance. It’s about control.

The Elettrica, the brand’s first all-electric model, marks Ferrari’s most daring leap yet. Fast Company Middle East gained an exclusive look at the EV’s technical aspects, with further design reveals to follow in 2026.

Revealed at Capital Markets Day 2025, it redefines what performance means in Maranello’s new multi-energy era, which now spans combustion, hybrid, and electric powertrains.

For a company that built its legend on the roar of a V12, silence was never the easy option. Yet the Elettrica isn’t about abandoning Ferrari’s soul.

The car is the result of more than a decade of experimentation, from the 2009 Formula 1-inspired hybrid systems to the LaFerrari and SF90 Stradale. Each model nudged the brand closer to an electric reality.

Now, after years of testing and over 60 patented technologies, Ferrari has built an EV that claims to retain the visceral engagement that defines its cars, only quieter, cleaner, and more precise.

DESIGNED FOR EMOTION

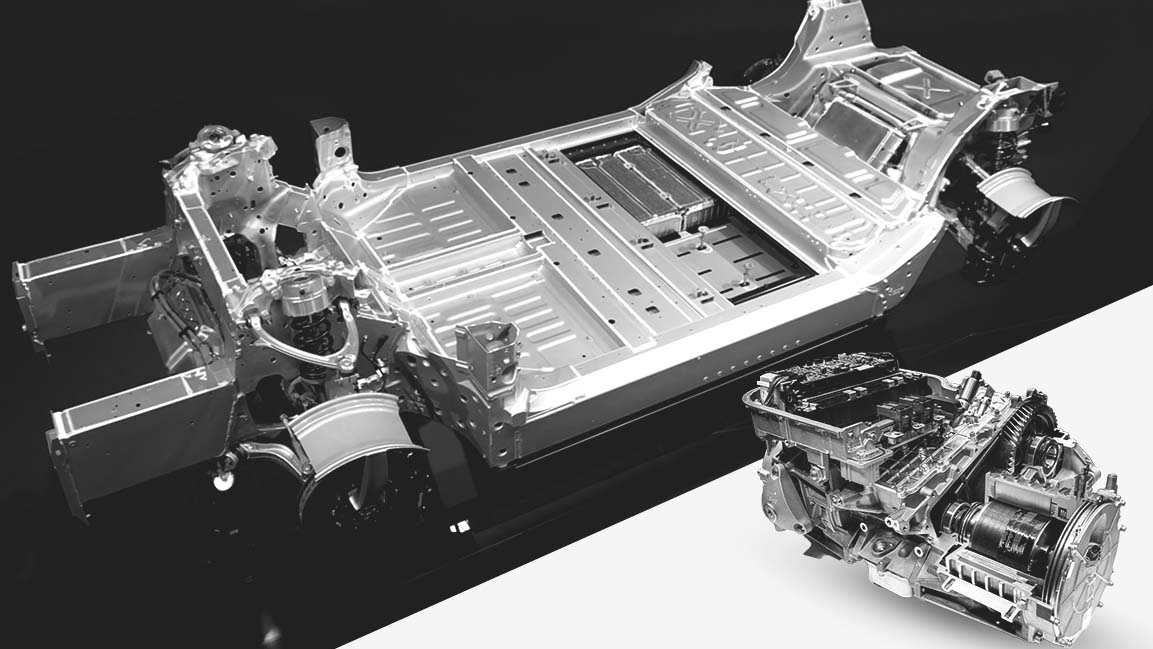

The Elettrica’s proportions align with Ferrari’s focus on balance and control. The floor-integrated battery lowers the center of gravity by 80 millimeters compared to a combustion model. Battery modules are positioned low between the axles, improving weight distribution and handling.

Electric propulsion introduced new engineering challenges, particularly in crash energy management. Engineers positioned the front shock towers, motors, and inverter to absorb and dissipate forces efficiently. The battery, fully integrated into the floorpan, is protected by energy-absorbing zones and a lower cooling plate. A proprietary assembly process increases chassis stiffness to preserve Ferrari’s signature precision.

At the rear, the company developed its first elasticized mechanical subframe. Elastomeric bushes add lateral stiffness while isolating vertical vibrations, minimizing road and powertrain noise. Hollow castings integrate the rear axle, suspension, battery, and active suspension inverters into a single load-bearing structure that remains accessible for maintenance. The result is a quieter, more composed ride without compromising dynamic response.

POWERTRAIN AND ELECTRIC MOTORS

The Elettrica’s dual-axle system houses four independent electric motors that allow precise torque vectoring. Nearly 75% of the aluminum in the chassis and bodyshell is recycled, saving 6.7 tons of CO₂ per vehicle, without compromising Ferrari’s obsession with balance and response.

The front axle delivers 210 kilowatts and can decouple at any speed, switching to rear-wheel drive for efficiency. Its integrated electronics achieve a power density of 3.23 kilowatts per kilogram, producing 3,500 newton metres of torque under full acceleration. The rear axle generates 620 kilowatts and up to 8,000 newton metres of torque in Performance Launch mode, with a power density of 4.8 kilowatts per kilogram. The system transitions between rear- and all-wheel drive in 500 milliseconds.

Ferrari’s permanent magnet synchronous motors draw directly from its motorsport programs, reaching 30,000 rpm at the front and 25,500 rpm at the rear. They use Halbach arrays to concentrate magnetic flux and maximise torque density while reducing weight. Ultra-thin stator laminations, Litz wire windings, and high-conductivity resin improve heat transfer and structural strength. Carbon sleeves secure magnets at high rotational speeds, while the front motors reach full rpm in under a second.

Every system is predictively managed 200 times per second, enabling the car to make preemptive adjustments to suspension, traction, and steering. The result is control that feels telepathic.

BATTERY, INVERTERS, AND ENERGY MANAGEMENT

The Elettrica’s battery was designed and assembled entirely in Maranello, fully integrated into the floorpan to lower the centre of gravity by 80 millimetres. Eighty-five percent of its mass sits beneath the floor, with the remainder under the rear seats. This layout shortens the wheelbase while maintaining a near-perfect 47:53 weight distribution. Front seats were repositioned to accommodate the battery cells without compromising cabin space or comfort.

Safety and efficiency shaped the design. Energy-absorbing structures, crumple zones, and reinforced suspension points isolate the cells from impact, while integrated cooling lines manage heat under load. An aluminium shell and cooling plates add protection without unnecessary weight. The battery also contributes structurally to the chassis, anchored at 20 points for rigidity. It achieves class-leading metrics, 195 Wh per kilogram in energy density and 1.3 kilowatts per kilogram in power density, while remaining fully serviceable. Modules and electronics can be replaced without disrupting the car’s structural integrity.

The inverters convert high-voltage DC power into AC for the motors and recover energy through regenerative braking. The front inverter, weighing just nine kilograms, delivers up to 300 kilowatts and is built using Ferrari’s Power Pack architecture, which integrates silicon carbide units, gate driver boards, and a dedicated cooling system. The system’s switching frequencies are calibrated to balance efficiency, heat management, and responsiveness.

At the rear, a toggling control strategy adjusts torque at 100 Hz to match driver inputs and extend highway range by about 10 kilometres. Ferrari’s Order Noise Cancellation technology mitigates vibration and resonance, ensuring the powertrain operates with the brand’s expected smooth precision.

SUSPENSION, TYRES, AND DRIVER ENGAGEMENT

A lower centre of gravity gave Ferrari engineers new scope to refine the active suspension system. Building on technology introduced in the Purosangue and F80, the system allows each wheel to control vertical forces independently. Working alongside four-wheel steering and the four-motor powertrain, it simultaneously manages vertical, longitudinal, and lateral dynamics.

The recirculating ball screw mechanism now features a 20 percent longer pitch, softening vertical impacts and improving ride comfort. Integrated thermocouples monitor shock temperatures to maintain consistent damping performance in varying conditions.

Tyres are redesigned for efficiency and control. Rolling resistance has been reduced by 15 percent without compromising grip, and five specific variants, dry, wet, winter, and run-flat, were developed to suit different driving environments.

Acceleration and regenerative braking are both tuned for engagement. Torque Shift Engagement allows the right-hand paddle to select between five levels of power and torque delivery, while the left-hand paddle modulates regenerative braking. The familiar Manettino dial adjusts the car’s dynamics across Ice, Dry, Sport, and ESC-Off modes, and the new eManettino lets drivers configure power distribution and axle drive for their preferred balance between range and performance.

SOUND AND EXPERIENCE

Ferrari chose not to emulate the sound of a combustion engine. Instead, the Elettrica amplifies the natural vibrations of its electric powertrain. A precision sensor on the rear axle captures these vibrations, which are transmitted through the chassis to create a mechanical, functional sound.

In everyday driving, the car will remain quiet, tuned for acoustic comfort. Under torque, the sound builds in response to throttle input, creating a sensory link between the driver and the drivetrain. The goal was not to mimic the past but to express performance through authenticity, a new form of emotion rooted in engineering.

Ferrari plans to reveal interior design concepts in early 2026, with the world premiere scheduled in the spring. In a world where most EVs chase silence, Ferrari’s engineers found something different, a new kind of voice. With the Elettrica, the brand demonstrates that even in an electric era, Ferrari remains committed to precision, performance, and above all, the driver experience.