- | 10:00 am

Why Sonos added 93 screws to its yo-yo shaped speaker

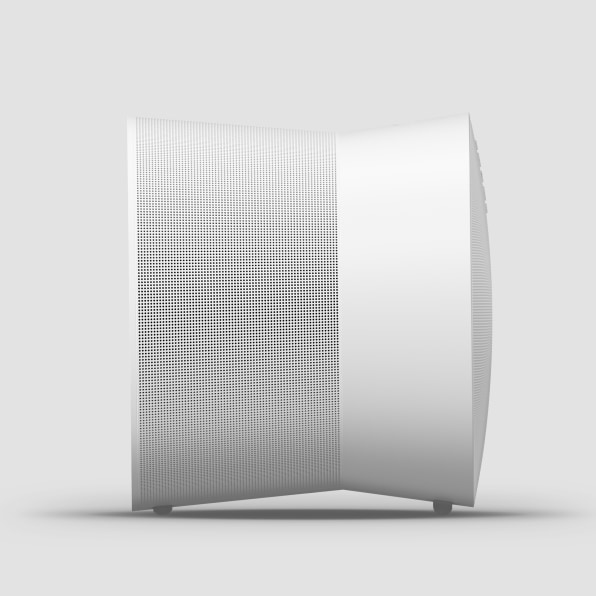

The Sonos Era 300 is the company’s first all-in-one spatial audio speaker, and its design breaks the mold.

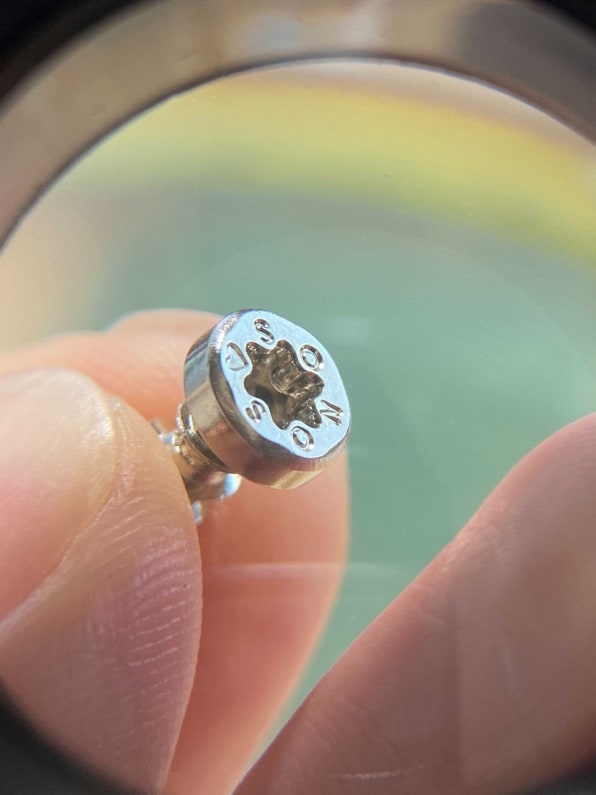

Sonos calls the shape an “hourglass.” I see a giant yo-yo. In any case, the company’s first spatial audio speaker—the Era 300 (out March 28 for $450)—breaks the mold of Sonos’s stoic, cylindrical products. And yet, the biggest shift for the company is hidden under the grill, where Sonos has eschewed the use of glue for nearly 100 screws holding together its Jenga tower of transducers, radio components, and wiring.

“What’s the big deal about glue?” you may ask. Industrial adhesives have taken over much of our built world, from prefabricated housing to farm equipment. With the ability to bond together components and leave no gaps, these glues enable the thin, seamless design of products like the iPhone, which popularized their use in industrial design.

As Sonos considered the form its first spatial audio speaker, the design team “started with a white sheet of paper,” according to Dana Krieger, VP of hardware design at Sonos. Whereas surround sound speakers place audio in the 360-degrees around your head, spatial audio places sound into the Z space, bouncing it up and down to simulate sound coming from above and below to make music sound like it’s live or those movie helicopters sound like they’re really flying overhead.

That means inside the case an array of loudspeakers aim in all directions—including, crucially, a single speaker pointing nearly straight up, at 10-degrees toward the ceiling. Engineers determined this 10-degree angle was key for optimizing the sound, and so in true form-follows-function design, that’s why the Era 300 tapers at this angle toward its hourglass center.

“It’s a profoundly different audio experience, and we wanted to celebrate that in the design,” says Krieger.

But while this design is intended to ensure good performance, Sonos was also concerned about improving the environmental footprint of its (mostly) long-lasting products. Everything about the Era’s design had to accomodate the incorporation of 93 screws. Some of those screws can be unscrewed to remove the case, which will reveal the many other screws that hold the internal scaffolding together.

Designed with standard tools in mind, the screws can be removed without any special equipment. But Krieger says that incorporating them into the design mandated an entirely new architecture—to solve problems ranging from keeping lines clean to ensuring that when an engineer does open the Era, they can actually reach the components.

When using adhesives in the past, Sonos had difficulty repairing its own products. Placed in the seams, under screens, and pretty much anywhere two components need to be held in place, adhesives make for slick products that mitigate shock and water better, but they are sticky to fix.

Indeed, repairing the deepest guts of an iPhone can involve suction cups, heat guns, and floss to handle easily damaged components and the adhesives adjoining them—a process iFixit clocked in at four full hours of labor. While Sonos declines to disclose what percentage of its products it has previously failed to repair, shifting to screws means that virtually any unit damaged in transit or broken after falling off a shelf should be repairable by the team and put back on the market as refurbished.

“Keeping a unit in-use, extending its lifespan, is our best way to improve our footprint,” says Krieger. It’s also why, on the new Era 100, an updated smaller unit that was also announced today, Sonos added 53 screws where it would have used adhesive before. Incorporating screws means that the Era 300 should be easier (and even greener) for people to service on their own, as well, but Sonos doesn’t endorse that practice, in spite of the ongoing right to repair movement.

“These are just tremendously complicated systems. We believe the best option for sound quality is not having people do this themselves, due to buzz and rub issues,” says Krieger. “Today the only way for servicing is to send it back to us . . . [though] we’re continuing to evaluate that.”

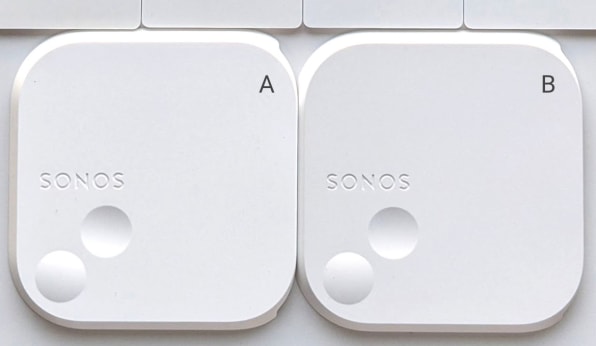

Screws weren’t the only environmentally-minded update in the Era line. For the first time, nearly 50% of the material inside the Eras is recycled. Given that recycled plastics contain all sorts of impurities that affect color, this concession meant that Sonos couldn’t reproduce its exact white finish that customers have been accustomed to since it debuted in 2015. Sonos products can mix-and-match into stereo pairs and surround sound systems, and the new white doesn’t perfectly match the old white.

As Krieger explains, it’s something that you can see side-by-side on swatches, but with a few feet of distance between the products, it’s virtually imperceptible—a fact Sonos validated in consumer research. “If I didn’t point out that shift to you, you would not have noticed,” he insists, also noting that for modern consumers, environmental values can outweigh perfectionism. “When we talk to people about why we made the change, there’s zero criticism.”