- | 8:00 am

The new paradigm for sustainable packaging

Think global and act local when developing circular packaging.

Sustainable packaging is not a niche concern for environmental enthusiasts. Investors, governments, businesses, and consumers are all demonstrating increasing interest in packaging circularity—that is, ensuring packaging materials can reenter the value chain after use. This approach can reduce pollution in the ocean and other ecosystems, slim down landfills, and boost local economies, while also often reducing costs for the companies that adopt it.

Today, most fast-moving consumer goods companies are working to incorporate circularity into their packaging strategies. But with dramatic variations in legislation and infrastructure across markets, finding the right strategy—even for a single product—can be a Herculean task. The only way forward is through an industry-wide approach that acknowledges and acts on regional differences.

GLOBAL-LOCAL TENSION

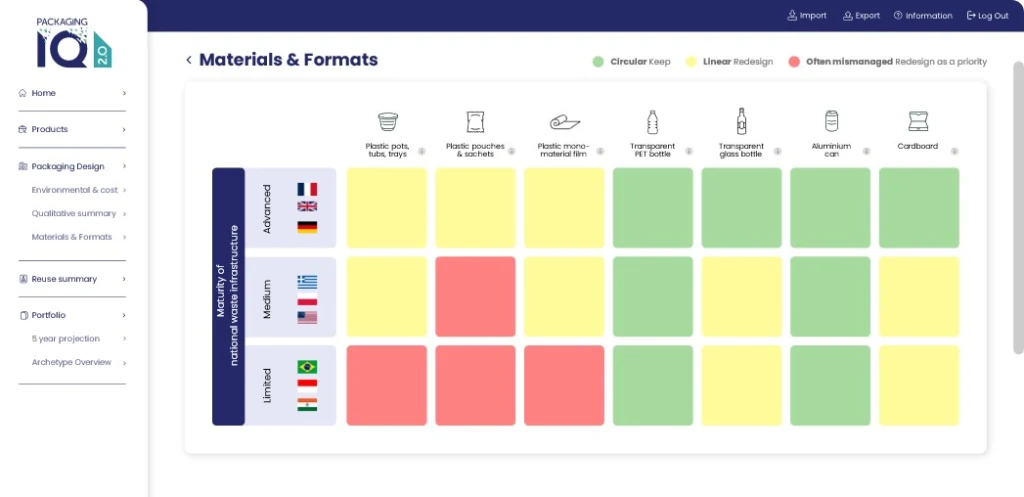

To develop truly circular packaging for a given market, companies must understand local realities. The recycling rates for a given material depend on several factors, such as the availability and processing capability of recycling facilities for that material, its quality and selling price, household behavior, and whether localities separate recyclable material from other trash. This means that decisions regarding which materials and formats to use in each market need to be made locally—often at a council or state level rather than country-wide.

In Brazil, for example, glass recycling facilities are concentrated in southern and southeastern parts of the country. In less densely populated regions such as northern Brazil, it can be prohibitively expensive to move heavy, fragile glass to distant facilities. Investing in local recycling infrastructure offers a more sustainable approach, though that involves considerable time and up-front costs.

Plastic recycling rates can also vary significantly across a region. In Germany, over 90% of PET bottles are recycled, whereas in Greece, another EU country, that number is just below 30%. The PET bottles recycling rate is over 40% in Australia and New Zealand, but less than 1% in the nearby Pacific islands. In practice, this means that a single product—say, the bottle that holds an internationally distributed beverage—will most likely be circulated in Germany but is almost certain to end up as a polluter in Fiji.

DATA AS A KEY ENABLER

No one company can solve the fragmented nature of market conditions. A challenge on this scale requires pooled resources, insights, and investment, as well as collaboration with NGOs, data providers, governments, and civil society. To get there, the industry needs to adopt a shared framework, including a unified set of decision-making tools.

In practice, those tools could look something like Packaging IQ, a platform envisioned by Delterra and Systemiq to ease packaging decisions based on granular system data at the SKU and market level, a view of the regulatory landscape, and a dashboard for analysis across markets and brands.

A minimum viable product version of this platform is set to be released by the end of 2024, grounded in the principles of Plastic IQ, which has already shown promising results in the industry. A major Indonesian retailer trained its sustainability team using Plastic IQ LITE, an educational version of the software that outlines circular solutions for plastic packaging. The retailer also plans to train its suppliers using the platform, deepening sustainability literacy across its supply chain.

In Brazil, a multinational animal health care company used Plastic IQ PRO to quantify the environmental impact of its packaging strategy within the country to help reduce its plastic footprint. Also in Brazil, the sustainability team at a leading events company took proactive steps by training their staff and suppliers on sustainability tools. They plan to implement a new requirement for all future events: Suppliers must have an aggressive packaging waste reduction strategy in place to be considered for selection.

In addition to adopting common tools, the consumer goods industry could foster collaboration by establishing global forums, engaging sector-wide stakeholders, and sharing data. Though these efforts should be global, the actions that result from them must be local. The circular economy of the future will be underpinned by a global network of small-scale, tailored solutions—and together, we can help build it.