- | 8:00 am

This solar-building robot is designed to solve one of the industry’s biggest problems

These massive robotic arms assemble panels at solar farms so that they’re ready to be quickly installed.

Three years ago, robotics engineer Banks Hunter drove deep into the Mojave Desert to see a solar farm under construction. Cardboard boxes with around 2 million solar panels were scattered over tens of thousands of acres. The boxes sat next to steel beams that had been hammered into the ground in a grid. Hundreds of people were walking up and down the rows removing the panels and screwing them into the steel mounting equipment, over and over. The whole process would take six months.

“My gut take was, this is insane,” Hunter says. “There’s no way that this incredibly manual process is going to scale toward the massive energy transition of the entire grid.”

SOLAR CONSTRUCTION HAS A LABOR SHORTAGE

Hunter, who’d previously worked at a startup making a surgical robot, had decided to transition to working on a climate solution. Before focusing on solar power, he partnered with Max Justicz, a former classmate from MIT, to spend months researching the gaps in climate tech.

They saw that solar was growing incredibly quickly. As the cost of solar panels dropped, the amount of solar power in the U.S. in 2020 was 25 times what it was in 2010. While it’s still a relatively small fraction of total power generation, it’s likely to become the largest source in less than two decades. But as Hunter and Justicz talked to solar companies, they learned that installers were struggling to find labor to build new utility-scale projects.

“I interviewed around a dozen of the largest solar construction companies in the U.S. and just asked them, ‘Hey, what are your key problems? Where are the bottlenecks for the company?’” he says. “And every single one of them told me, ‘Well, we’re drowning in demand for new projects.’”

In some cases, solar construction companies were turning down projects because they couldn’t find workers. In other cases, workers were commuting for hours to get to sites with no hotels or grocery stores nearby.

Hunter and Justicz realized that part of the construction process could be automated. They launched a company, called Charge Robotics, to develop robots for the task.

HOW SOLAR FARMS ARE BUILT NOW—AND HOW ROBOTS COULD HELP

Right now, installing massive solar farms takes four main steps. First, steel piles are hammered into the ground. Then forklifts pick up boxes of solar panels and distribute them across the site. “It doesn’t sound like it would be a major project, but [it is] if you have 10,000 acres and a million solar panels to distribute, and each of those panels weighs a couple thousand pounds, and you’re out in a massive, muddy field,” Hunter says. The third step involves screwing together the frames that hold up the panels and attaching them to the steel piles in the ground. Finally, crews walk through the field attaching the solar panels.

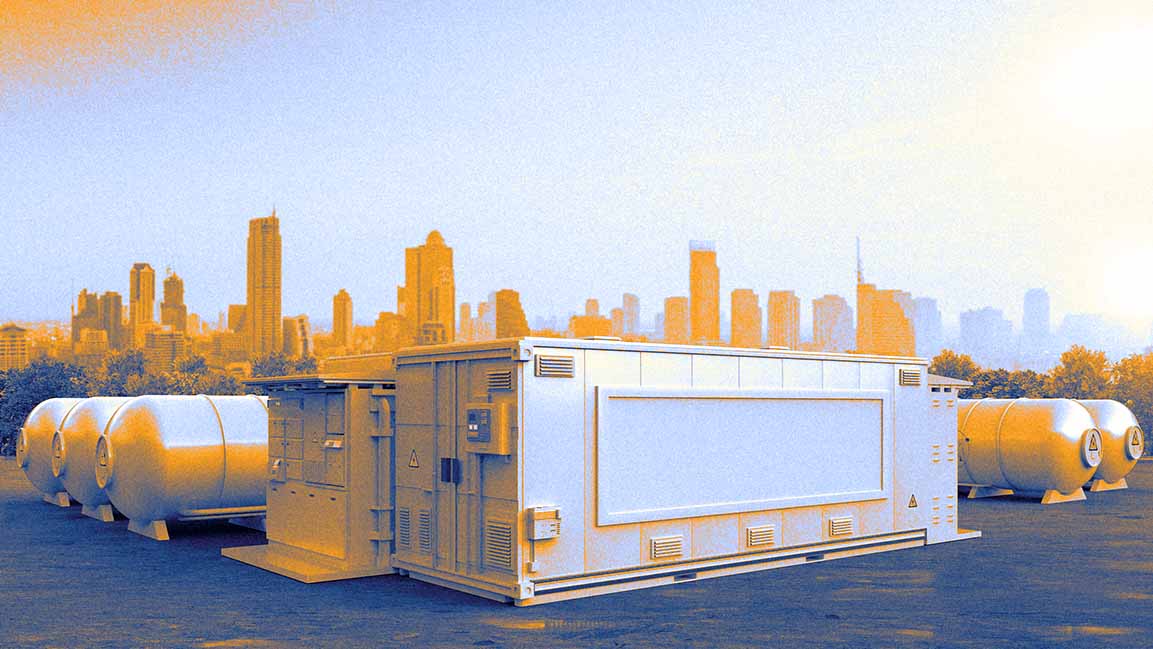

Charge Robotics doesn’t change the first step; workers still drive steel piles into the ground. But the company developed a portable factory that could easily be moved around a solar site. Outside, it looks like a shipping container. Inside, robotic arms screw together solar panels and mounting brackets. Then vehicles can deliver the final assembly around the solar farm.

The system, called Sunrise, uses only a small crew of operators, drivers, and technicians. It’s possible to install as much as 1 megawatt of solar power in a day, and a project could use multiple systems at once. The Sunrise “keeps pace with a traditional crew of about 80 people,” Hunter says. On a large site, it could be used in combination with a traditional crew—and could possibly double the installation speed.

SCALING UP THE TECH

The startup partnered with Solv Energy, a large solar installer, on a pilot late last year. The robotic system worked on a small corner of a larger site to demonstrate the tech. “There’s just so much that you can’t say you know for sure until you’ve actually taken the thing into the field and put it through its paces,” Hunter says. “Honestly, construction companies are rightfully wary of new technology. There have been many incidents of people trying to pitch robotics or new technology in the construction space. And often it doesn’t go so well. I’m happy to say that in this case, Solv was absolutely blown away by what we were able to do there.”

The team is tweaking the design to make it more durable—industrial robotics are designed to work inside clean factories, not in dusty fields. Over the next year, it plans to scale up and commercialize the robots. In 2025, the team expects to begin working on large-scale installations. There’s already huge demand, Hunter says. Three major solar construction companies have signed $31 million in letters of intent with the startup.