- | 9:00 am

As freshwater gets scarcer in the Middle East, could this tech be a solution?

The innovators liken the solution to 3D printing drinking water on the spot and distribute it in virtual pipes; chem-free, plastic-free, and carbon-neutral.

Water is easy to take for granted. It falls from the sky. Yet the shortages are making water a precious commodity. That represents an opportunity for innovators.

About four years ago, Martin Renck and Ulf Stenerhag went on a conference trip to Seychelles. They stayed in an apartment with all the luxuries except for drinking water. They had to go to a grocery store a few blocks down the road to buy dozens of bottled water. Then three things happened: They saw the sheer volume of bottles in front of them; they noticed the piles of plastic, the microplastics dissolved in the water, and the human right to clean water.

“It struck us that there is a tremendous need for a future-proof drinking water solution that addresses all the critical aspects and cascade effects. Not much innovation had happened since the Roman aqueducts,” says Renck.

The existing water supply systems, built before we were aware of microplastics and PFAS and before many of the drugs, medicines, and industrial chemicals used today were even invented, that allow contaminants to go unchecked through the system needed an overhaul.

In the last 50 years, the infrastructure has degenerated as the world population doubled, increasing pressure on the aging systems.

“Because of antiquated technology and uncontrolled leaks underground, there is a lot of loss of water both upstream and downstream, and lots of funky stuff in the offered water,” says Renck.

A COMPLETE SOLUTION

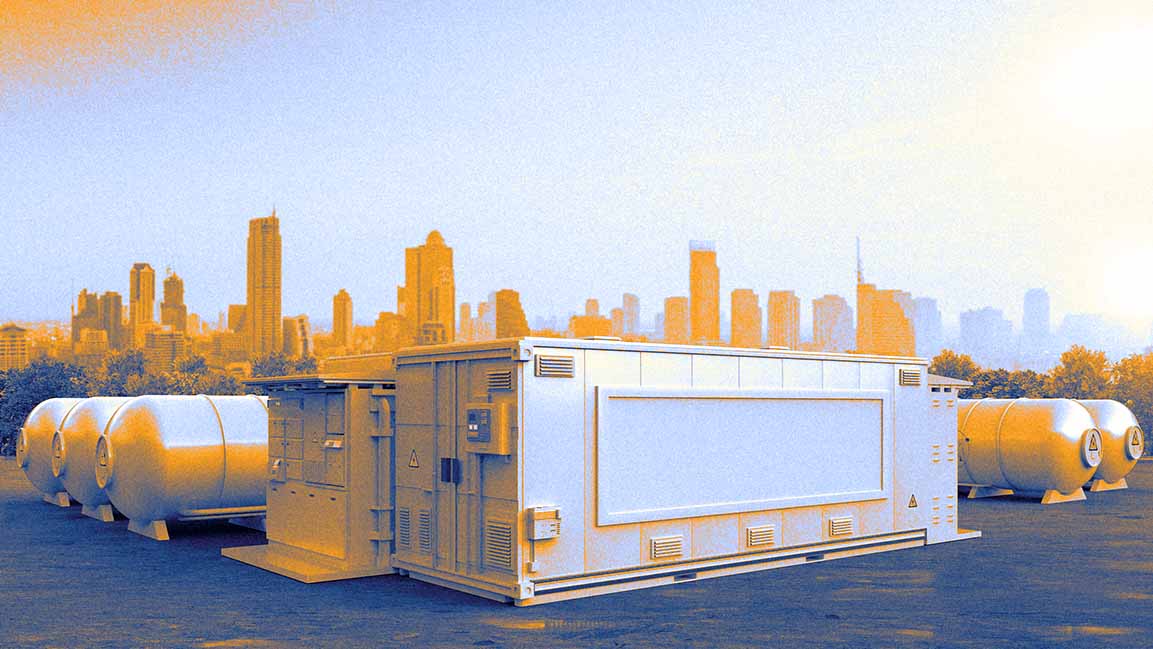

Today, Renck and Stenerhag are co-founders and partners of a Swedish startup called Wayout. They have developed sustainable solutions for local production and distribution of safe drinking water – its solar-powered micro-factories treat water from any source, including seawater, then it is remineralized and distributed in refillable stainless-steel vessels and dispensed through smart taps.

The system is digitally connected, where data is used to communicate water information and optimize the circular distribution.

“It’s a complete solution from production via distribution to water consumption within a circular and digitized system,” Renck says. “It also eliminates single-use plastic using lightweight stainless steel vessels that are cleaned and refilled automatically.”

Now, the tech company is expanding to the Middle East with a permanent showroom at Alserkal in Dubai. Last year, the startup was one of 20 participants at Innovate, a global initiative by Masdar City providing a platform for innovation-focused startups to showcase their technologies and solutions.

Its built-in technology produces drinking water from any source – salt water, gray water, rainwater, atmospheric water – even industrial wastewater.

It is a sign that advanced water tech systems can be commercially scaleable and new technologies are transforming wastewater into a resource for a source of drinking water.

So how is any source water converted into safe drinking water?

“We base our water treatment set-up on an as versatile as possible standard fit-out,” he says. The vital parts of the filtration process include sand pre-filtration, nanofiltration, quadruple reverse osmosis, UV-filtration, and ozone cleaning.

The cleaning process removes all contaminants, including pharma residue, PFAS – also known as forever chemicals – and microplastics. “We also remove wanted minerals, which we then add to the treated water by natural processes after the filtration is completed.”

Chlorine and citric acid, usually needed in piped water to suppress bacterial growth and odor, and PFAS and microplastics are common fallouts when distributing water in single-use plastic bottles, especially in the warmer regions of the world, are not added.

AUTOMATED MICRO-FACTORY

Renck says the system is built around total automation, which is guided by utilizing a series of computers (PLCs) and IoT across multiple processes internally within the micro-factory and outside across vessels and dispensers.

“This produces a lot of data which we represent in a digital twin of the entire system. The data is analyzed using AI, and the business intelligence is made available on a dashboard through which operators and stakeholders can then plan, predict and optimize everything from inventory and distribution to resource efficiency and eco-footprint.”

And as climate impacts keep getting harder to ignore, the world of climate adaptation tech keeps growing.

In addition, with this innovative water purification, distribution, and dispensation system, the tech reduces the use of plastic bottles, which aligns with the UAE’s ambition to be free of single-use plastic bags by 2024 and promotes innovations in non-conventional water resources.

“Our innovation ties into this transition towards true sustainability by solving challenges like local and decentralized production and thereby increasing resilience, like providing quick to deploy plug-and-play systems for disaster preparation and relief, and committing to providing a reliable, steady flow of highest quality drinking water with a minimal eco-footprint.”

Giving a sense of how it compares with the traditional systems in terms of costs, operations, and carbon footprint, Renck, when it comes to the efficiency of the use of source water, traditional systems lose up to 70–80% along the way to the endpoint. “Our rejection is less than 10%. One liter of single-use plastic bottled water uses three liters of treated water and around 2,000 times more energy than tap water – our micro-factories are solar powered and recycle 100% of the produced water.”

While traditional systems always push water through crumbling pipes underground or in leeching single-use plastic bottles, Renck says Wayout systems can be leased on a pay-as-you-go platform with everything included.

“Because we produce locally, we eliminate all long-distance transport and thereby eliminate substantial greenhouse gasses released by fossil-fueled transportation.”

He likens the solution to 3D printing drinking water on the spot and distributing it in virtual pipes; chem-free, plastic-free, and carbon-neutral.

In a region where water has always been as scarce as it is precious and where people come together to collaborate on sustainable solutions, the company aims to work with like-minded local partners — industrially, financially, and technologically.

“We are inspired by the innovative initiatives in the UAE, both around eco-awareness and the transition to concrete practices making sustainability possible.”

The company is in talks to expand across the Middle East and throughout the island nations in the Indian Ocean, sharing similar challenges around providing future-proof drinking water for their people.

“We’re constantly in a state of research and development, and have been successfully able to combine deep technological innovation with speed to market,” says Renck.