- | 6:00 am

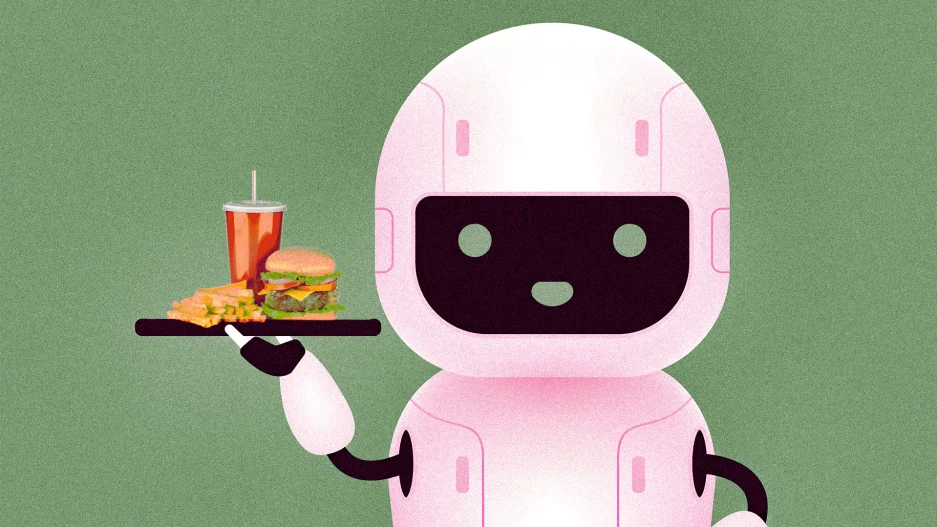

Chippy comes in peace: How robots will coexist with humans in the $800 billion restaurant business

Amid the great resignation, the future of autonomous systems in fast-food restaurants may not be as dystopian as we thought.

One minor quibble with the show Westworld is that there are too few scenes of characters leaving the park to explore less murder-y elements of the near-future. If one company in the world of this show is so advanced that its robots are revolting, what is every other kind of company doing with similar tech?

Imagine two guests head out of Westworld to go get some chow. A writer fleshing out this scene might do a bit of research and land on something like a robot salad spot, a fresh pizza kiosk, or an autonomous Korean fried chicken joint. Or at least, they would if they were lazy. It probably goes without saying but: All of those things already exist.

If you’re dreaming up the culinary future in 2022, you have to go further than “robots.” That future is already here. It’s just not as scary—at least not so far—as the entire machine-uprising canon has suggested.

Robots in science fiction are often synonymous with dystopia. Whether it’s Westworld, The Matrix, or Terminator 2, too much A.I. equals time for humans to die. But as the cofounder of an automated pizza startup, Benson Tsai was inspired by less depressing sci-fi fare, the kind where robots are just there in the background, being awesome, rather than battling for liberation.

“I’m a child of the ’80s. I grew up when we were very optimistic for the future,” Tsai says. “The Jetsons kitchen, the rehydrating pizza machine from Back to the Future II, the food replicator from Star Trek—science fiction always sort of points us towards what we actually want and desire in society. And I just kind of get excited about making that a reality.”

This may sound like something a robot would say, but what if some of the robot restaurants were off to a good start? What if they actually solved some human problems instead of solving the problem of humanity itself? What if their vibe was a little more . . . utopian sci-fi?

THE JOB-REPLACEMENT DOOMSDAY SCENARIO

Fast food’s history of innovation is inextricably linked with advances in technology, from inventing the drive-thru as a response to the development of interstate highways, to the Doritos Locos Taco. It was always inevitable that advanced robotics would find a home in the quick-service restaurant business.

What people fear most urgently about robots in restaurants, though, is not malevolent sentience, but job theft. Media has been beating that drum since the early-aughts explosion of kiosks in grocery stores and airports, at which point McDonald’s also started testing them. A CNN story from 2014, mainly describing Panera Bread’s transition to kiosks, declares in its mournful headline: “Robots will replace fast-food workers.” The idea was not exactly implausible. Fast-food workers had just begun agitating for better pay and unionization with the Fight for 15 movement, to which McDonald’s responded by outright threatening to replace them with robots. This is the kind of strategizing that gets us to Westworld.

Recent forecasts for the near-future have been rosier. The World Economic Forum estimated in October 2020 that, by 2025, robotics would displace around 85 million jobs, which is very bad, while also creating 97 million new jobs, which is very, very good. Beyond such estimates, a strong reason to worry less about robots stealing jobs from American humans is that the restaurant jobs robots have started to replace are the ones no worker wants.

“It’s not taking jobs because those jobs are going unfilled every day in millions of restaurants around the world. People are not showing up for the fry station,” says Jake Brewer, chief strategy officer for Miso Robotics, a company most known at the moment for Flippy, a robotic arm that mans the fry station—or perhaps robots the fry station—in more than 100 White Castles.

“This is not new, either,” Brewer adds.

Even before the pandemic, restaurants such as Panera Bread were reporting 100% turnover every year. (One wonders, of course, if a significant minimum wage hike might have made a difference there.) When Miso installed its first-ever Flippy in 2018, at a Pasadena Caliburger, the intention was to help the small but global chain with its staffing problem.

The reason the fry cook is called Flippy and not, say, Fryzo, is because its original incarnation actually flipped burgers. And the reason Flippy flipped burgers is because Caliburger had trouble keeping cooks on the grill. Trainees immediately hated the heat and the pace and the pressure. Few who reached proficiency hung around in the role for too long, meaning Caliburger was constantly training new cooks.

The original Flippy proved imperfect at what it was intended to do. Although it succeeded in efficiently cooking and flipping burgers, a person still had to put the meat on the grill and later move it to a bun. Human labor remained essential, only with an even duller central task. Ideally, Miso’s robot would free up workers to do more complex or customer-facing tasks. It hadn’t yet. Gradually, Flippy transitioned to frying, a role it was able to perform without human assistance. (Miso’s product roadmap does eventually include a retooled burger-flipping bot. In the meantime, it’s released CookRight, which is essentially burger-Flippy without the arm—just the computer vision and temperature-gauging, to help grill cooks know when to flip what and to keep track of orders. CookRight is a noninvasive way to turn restaurant workers into RoboCook for the duration of each shift, which is what most restaurants expect from them already.)

Jobs like fry cook represent the core paradox of the fast-food worker experience. The promise of McDonald’s is an identically satisfying meal everywhere, every time: universal uniformity. The fries should be equally crispy at any hour of day, at any location in the world. But delivering this promise, or even coming close, requires the roboticization of humans; cultivating their ability to execute rote tasks in perpetuity at a high level. It’s a, uh, rather tall order, even before considering the deeply human difficulty of doing math while sweating grease and nursing a knuckle burn. Several fast-food jobs operate the same way: demanding assembly-line perfection in a chaotic environment. Toss in the fact that fast-food workers also have low wages, few benefits, and are generally treated poorly, and the labor crisis becomes less of a mystery.

But if the harsh realities of capitalism got workers into this mess, perhaps the harsh realities of capitalism can also help get them out of it.

WHEN YOUR NEW COWORKER IS A ROBOT

Jake Brewer first encountered Flippy as someone in the market for a burger robot. In 2018, Brewer was a VP at CKE Restaurants when Miso approached him about getting the original Flippy into Hardee’s and Carl’s Jr. It had only been a year since CKE’s CEO—and failed candidate for President Trump’s Secretary of Labor—had expressed his affinity for robots over humans, because “They’re always polite, they always upsell, they never take a vacation, they never show up late, there’s never a slip-and-fall, or an age, sex, or race discrimination case.”

When Brewer first laid eyes on Flippy in action, it was like he had witnessed the fast-food equivalent of the moon landing. “They were showing me what they were calling internally Spaceship Flippy, this big thing,” Brewer says, and he thought, “Oh my gosh, you’re so close.” But what was still left to do flopped that excitement to a no. “You’re breaking fire code in every one of my restaurants, because you’re impeding on the aisle way too much. [There was] a list of about 10 other things. Maybe if it did X, Y, and Z, I actually could redistribute labor. And, oh, by the way, if it was this size, then I could actually put it in 80% of my restaurants versus like less than 1% of my restaurants.”

CKE was intrigued but ultimately passed on the burger robots. But Brewer had seen the future. A few months later, he started working for Miso.

What Brewer—along with some other veterans from restaurants such as Chik-fil-A—gave Miso was deep industry insight into fast-food pain points. It’s this collective expertise, rather than its knowledge of computer vision or artificial intelligence, that Miso considers what Brewer calls the company’s “internal North Star.”

Flippy’s problem, Brewer and his colleagues realized, was that it wasn’t yet ready to be a team player, even though it required human assistance. This is what’s known as cobotics: when humans interact with robots to get tasks done, as in Miso’s original design (and also CookRight). It’s the kind of tech that the hospitality industry is increasingly adopting to make work easier for housekeepers, cleaning staff, and property managers. (According to The Matrix Resurrections, smartphones have dragged all of our personal lives into the cobotics space.) But the Miso team wanted the next generation of its signature product to be fully autonomous, giving more employees a chance to shine with skilled-up roles and more complex menu item builds.

White Castle found success in its first experiment with Flippy as fry cook in 2020—and then ordered ten more for its locations. Last November, Miso debuted the autonomous second-generation fry machine, Flippy 2, at a White Castle in Illinois, and the brand was so satisfied with the upgrade, it ordered 100 more earlier this year. An internal release touts the fully autonomous robot’s “immediate positive impact on daily operations and the productivity of team members.” No small help at a time when fast-food restaurants have found it harder to staff up than just about ever.

Another factor in Miso’s value is its adaptability. The company gives chains the tools to modify Flippy’s basic platform, whether it’s piloting a potential Wingy for Buffalo Wild Wings last fall, or launching a tortilla chip maker, Chippy, at a Southern California Chipotle later this year.

This isn’t, your roboticists were so preoccupied with whether or not they could, they didn’t stop to see if they should. It’s practical tech solutions for wild modern problems.

PIZZA MADE BY ROBOTS AND ROCKET SCIENTISTS

While Miso is reconfiguring how existing fast-food restaurants can work with robots, Stellar Pizza is busy prototyping what a robot-forward fast-food restaurant will look like.

SpaceX engineers get hungry, too, and some of them even have broad, adventurous palates. Benson Tsai, who designed batteries for the Dragon spacecraft and Starlink internet satellites, would often eat out with fellow foodie engineers, despite having gourmet chef Ted Cizma on staff in the campus kitchen. One day, when picking up a DoorDash order, Tsai found himself accepting delivery bags from a 10-year old child. Afterward, he couldn’t stop thinking about the steps that had somehow led to this strange moment.

“It made me realize that there was something wrong with the system,” Tsai says. “Whether it’s more efficient to have a second person handing off food or the mom maybe just couldn’t afford childcare, there was just something that felt wrong. . . . And I just started looking into the inefficiencies of the third-party food delivery world.”

Automation had long been on Tsai’s mind. After watching, amused, through the window of a Krispy Kreme many years ago, as dozens of donuts seemingly glazed themselves, he noticed automation creeping in everywhere. Whether it’s in manicures or drug prescription refills or those kiosks that grocery stores literally cannot seem to refuse (Albertsons took theirs out in 2012, only to bring them back seven years later), everyone seemed to be in the business of bots. And business was booming. The fact that automated manufacturing has helped drastically lower the sticker price of TV sets did not escape his attention either.

So in May 2019, Tsai cofounded Stellar Pizza with fellow SpaceX engineers Brian Langone and James Wahawisan, with the vision of making better pizza, and making the lives of delivery drivers a little better, through automation. Together, the three convinced over 20 of their former colleagues to jump (space)ship and join the Stellar quest to tackle robot-made pizza with the ingenuity of rocket scientists. (Chef Ted, as he is known, eventually came along as well.)

Stellar’s concept, which took two years to design into reliable functionality, is a touchless pizza-making machine, automated from end-to-end, that lives inside a food truck. A cooling unit expels doughballs into a double-sided heated press, where they are mashed and shaped into pie form. (It would be difficult to describe any portion of this process in a remotely appetizing way.) The machine then slides the pie along to the topping line, layering on sauce, cheese, and whatever else makes a pizza supreme, in 3D-printer-like fashion, powered by the kind of precision one associates with aeronautics. Finally, a mobile ledge pops the pie into one of four stacked ovens, while making exactly the whirring noises you are imagining. Voila: easy pizza.

Stellar will launch in Los Angeles this summer, with food trucks serving as stationary ghost kitchens for third-party delivery. The expected upside for those drivers is that they’ll be auto-alerted when their pie is being made, and told exactly when it will be ready. If things go as expected, Stellar will eliminate for its drivers the gobs of time that many currently spend waiting on orders from other restaurants to be finished.

What Tsai hopes will be the key to Stellar’s success, though, isn’t the novelty of robot-grade easiness, but the taste of the pizza itself. Tsai doesn’t see Stellar as a robotics company that makes pizza, but as a pizza company that uses robotics.

He convinced the pizza consultant Noel Brohner—who has been dubbed the pizza-dough maestro of Los Angeles and who has worked with everyone from acclaimed chefs to Tom Hanks—to work with Stellar after turning down several offers from other startups with a tech-forward approach. All the others had come across as too gimmicky. Brohner was impressed, though, by the quality of Stellar’s ingredients, procured from a savvy selection of vendors. And he was quickly convinced that this wouldn’t be another Zume, which reportedly raised more than $400 million for autonomous pizza trucks that made pies with “cheese dripping everywhere, [and] paltry little sauce,” as one review concluded, before flaming out spectacularly back in 2020 and pivoting to making plant fiber-based products, which, yes, is deliciously ironic.

“Sometimes you can find that automation actually helps the process as opposed to trying to replace a person with an automated process that’s 80% as good as a human but 60 times faster,” Brohner says. “Because in the end, it’s great to be automated, and it’s great to have efficiency and it’s great to save money, but not if the pizza sucks.”

THE FLUCTUATING LIMITS OF AUTOMATION

Not everything needs to be a synthetic arm or a kiosk, as anyone who’s ever used a kiosk can attest to. There’s a level of artistry in customer service and many aspects of cooking, and it can’t entirely be replaced—or at least, it shouldn’t.

“Could we automate everything? Yeah, I genuinely believe so,” says Miso’s Brewer. “Given enough time and scope, I believe we can do that. But I don’t think we ever will.”

Brewer brings up Hardee’s biscuits as an example of something Miso wouldn’t attempt to automate. The steamy, crumbly carb-bombs are branded as hand-cut and freshly baked. Whether a machine could build a better biscuit is irrelevant to the interests of Hardee’s customers, who were weaned on whatever sunny intangibles are infused in human-made biscuits.

Chipotle’s tortilla chips, as a counterexample, are known nowhere as “hand-fried.” Having a robot fry ’em up violates no sacred tortilla purity. At least, not to anyone already eating at Chipotle.

When restaurant chains dig in too deep, too fast on automation, their efforts have been poorly received. McDonald’s and Starbucks are among the worst offenders. Together, they embody (or enrobot) the primary fears around restaurant robotics, namely the ones about replacing jobs. While Miso tinkers with Sippy—the drive-thru dispenser that pours, lids, and organizes beverages for other workers—McDonald’s in 2019 acquired an AI startup and then created something called McD Tech Labs as part of an ongoing effort to automate the drive-thru process entirely. When it realized late last year that maybe a fast-food giant didn’t have the skill set to bring this vision to life by itself, it sold the division to IBM and then partnered with the venerable tech giant. The goal to automate the drive-thru remained intact.

Around the same time that Miso introduced Flippy 2, Starbucks opened its first, widely panned Amazon Go shop in New York, the logical extension of a typical present-day Starbucks, where the robotic devices seem to outnumber the people. “There are certain brands that will go fully autonomous,” Brewer says. “It’s definitely coming, where you’ll drive up to a box that, just for the sake of conversation, has a green mermaid on its side, and the box is about the size of a cargo container, and you drive through and you get your Pikes Peak, medium roast, room for cream, and no one’s in that restaurant.”

For now, Miso’s robots have oddly come to be considered somebodies in their restaurants.

Flippy 2 was designed with a Plexiglas wall between it and the other team members. This simple tweak, the company’s research suggests, creates a psychological barrier between the workers and the robot, so that the latter scans as just another kind of worker doing another kind of job. According to Brewer, franchise managers will talk about their robot like it’s a person—”Flippy had a good week this week”—and many of their staffs have given their robots nicknames. It’s only natural that the roboticization of humans in fast-food restaurants would be followed by the humanization of robots in restaurants.

THE DELIBERATE MISTAKE THAT SIGNALS PERFECTION

Perhaps the most human trait a robot can take on is being prone to error.

Nevielle Panthaky, Chipotle’s VP of culinary and menu development, had one minor quibble with the tortilla chips that Chippy produced for the chain. Miso’s machine had ensured that each chip received an ideal and equal amount of fresh lime juice every time, while customers seemed, in Chef Panthaky’s view, to enjoy finding the occasional super-limey chip amid a cluster of more pedestrian ones. They wanted the random chaos. Miso took the note and got to work on approximating human-fried and seasoned tortilla chips, which is what guests can expect to find when Chippy launches at a Chipotle later this year.

Unlike at Westworld, the robots in these restaurants are so far only malfunctioning intentionally and deliciously. May they continue doing so until hackers wreak havoc with them, or they achieve malevolent sentience, at which point you might want to just wait for the movie.