- | 9:00 am

Cooling technology needs a rethink. And the Middle East may have some ideas

Demand for air conditioning will only increase. From using AI to liquid nitrogen, these innovators are making sure energy-efficient air conditioning is within sight.

The UN Climate Change Conference in Sharm El Sheikh, Egypt, to be held 6-18 November, and the FIFA World Cup Qatar 2022, which kicks off two days later—are sure to focus minds on the fact that the Middle East is rapidly getting hotter. Much hotter, now warming at twice the global average and could be 4°C warmer in 2050.

More than 60% of Qatar’s electricity is already used for cooling air. That figure is higher in its neighbor UAE, where air cooling systems account for up to 85% of buildings’ energy consumption.

The widespread reliance on air conditioning, which uses a barely-tweaked 120-year-old technology, also contributes to the climate crisis. It’s a vicious circle. Carbon emissions create global warming, which ramps the desire for air conditioning, creating the need for burning fuels that emit more carbon dioxide.

“Air-conditioning innovation is like nuclear fusion. It’s always at least 20 years in the future,” says Lin Kayser, CEO of Hyperganic Technologies, an AI-based design-software firm in Munich. “Some scientists, for instance, have created metamaterials that they say could eventually reflect heat away from buildings straight into outer space. This sounds fantastic, but we need a workable solution now.”

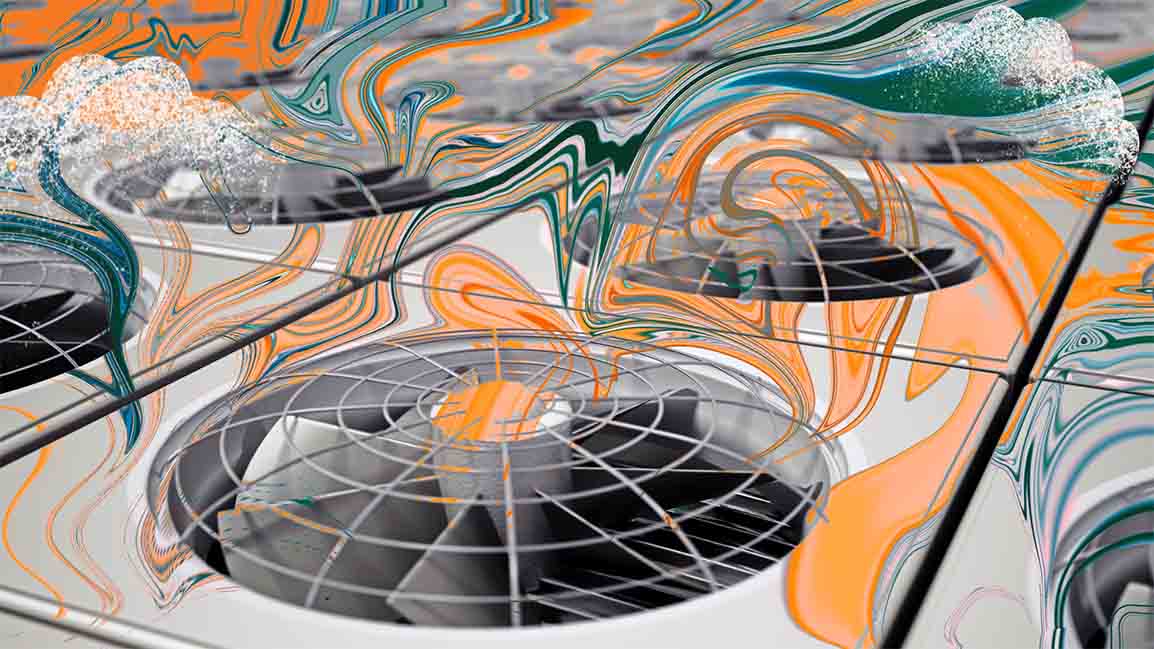

Kayser reckons he has one. Traditional air conditioners push warm air outdoors through a heat exchanger, which compresses a refrigerant gas into liquid. However, as well as guzzling huge amounts of electricity, these exchangers require a large surface area and an elaborate structure of airflow tunnels governed by the limits of engineering and manufacturing processes.

Hyperganic’s AI-based design platform enables engineers to 3D-print heat exchangers with radically different structures, using elements inspired by the intricate designs found in nature, such as corals and flora, to increase the surface area and optimize airflow. Kayser says this could lead to ten times as efficient residential air-con units as conventional ones for the same cost.

A NEW HEAT EXCHANGER

To achieve this, the firm has partnered with EOS, a leading German maker of industrial 3D printers, and Abu Dhabi’s Strata Manufacturing, which produces aircraft components for the likes of Boeing. Kayser says he has many designs for a new heat exchanger already and has performance data on some. The aim is to have a prototype ready for the 2023 UN Climate Change Conference in Dubai, and a pilot production line will follow.

“Eating vegan food and cycling everywhere will not save the planet. The only way to save it is through better engineering,” says Kayser. “However, most innovation in the past few decades has been in IT. A computer from 40 years ago looks very different from one made today, but if you look at the cars, aircraft, and appliances from 1985, the engineering hasn’t changed that much.”

Air-con accounts for about 10% of the world’s electricity use, and it is forecasted that ten units will sell every second for the next 30 years. Yet, he says, most air-con systems, especially the compact residential units which make up half of the global market, are not efficient. “Their technology is simple; it has been optimized for cheap manufacturing using sheet metal and pipes.”

Kayser, a serial entrepreneur who has previously invested in robotics, advanced materials, and underwater exploration, founded Hyperganic in 2017. Transferring the AI within algorithms from one application to another—or as he calls it, “algorithmic engineering”—will speed up innovation in the engineering of physical things, he says, boosting the development of several new products.

“We’re not even inventing something new. We’re just bringing advanced manufacturing capabilities and AI together, so we take the knowledge we already have but can create, test, improve and iterate much, much faster,” he says. “In the case of air-conditioning, we are looking at many things we already have but have never used in an air-con unit.”

One of the first components Hyperganic produced, combining algorithmic engineering with industrial 3D printing, was the world’s largest aerospike rocket engine, with a labyrinth of complex cooling channels. Unveiled by Hyperganic and EOS in May, the 30-inch-high combustion chamber would have presented any engineer or manufacturer with a colossal challenge. Hyperganic’s AI algorithms, however, created hundreds of designs in days. One of EOS’s specialist machines printed the best, which uses lasers to heat and fuse metal powders one layer at a time to build parts.

“By combining algorithmic engineering with industrial 3D printing, we can engineer air-con units that, over a year, consume only 10% of the energy of a conventional device,” says Kayser. “We can do this at scale and at a competitive price point with traditional units.”

Moreover, he is convinced he has signed up the perfect manufacturing partner in Strata. “Within a few years, this company built one of the most advanced factories for carbon composite aerospace parts in the desert,” he says. “Even during COVID-19, when most companies in the world shut down and complained about supply chain issues, Strata expanded its production capabilities and built a new factory arm from scratch.”

“They can help us bring this product to life in no time at all,” he adds.

TARGETED COOLING

If Kayser’s inspiration for a new heat exchanger was the designs found in natural phenomena, Dr Saud Ghani, the engineer behind the innovative cooling technologies used in Qatar’s glittering new World Cup stadiums, was inspired by old-style car radiators.

As well as retractable roofs, heat-reflecting facia, and other architectural hacks used in the world’s hottest zones, cooled air wafts into the stadiums through specially positioned grilles in the stands and large nozzles facing the pitch, like the dashboard of a 1954 Pontiac. Cooled air is then drawn back, re-cooled, filtered and pushed out using air circulation. All the angles and speed of air movement have been carefully calibrated over the past decade to maximize cooling while minimizing the possibility of fans suddenly being blasted by cold air.

Saud calls this “targeted or spot cooling,” meaning that cooling only takes place where people are. His eureka moment came when he realized he had to cool only people, not the stadium’s upper reaches.

The engineer claims this technology is about 40% more sustainable than existing techniques. Stadiums need only to be cooled two hours before an event, which significantly reduces energy consumption. Moreover, the temperature inside the venue will be relatively low—no more than 17.2°C—regardless of the temperature outside.

The air blown into the stadiums is cooled by the water refrigerated by huge absorption chillers, which use energy from water heated by solar panels and then stored in temperature-controlled tanks beneath the venues.

There has been much interest in this type of solar district cooling as an alternative to running air conditioners on fossil-fueled electricity in hot countries with a lot of space, such as Saudi Arabia. One recent study suggested that to cool a district of 100 buildings, with each structure housing up to ten people, you would need a solar field a little bit larger than a football pitch.

“All of our projects have a legacy and a scientific value that the community benefits from,” says Saud, noting that the outdoor cooling system developed for the World Cup has also been used in Doha’s Katara Plaza, Qatar’s first air-conditioned outdoor shopping mall. Here, paved walkways have elegant air vents to cool shoppers as they admire the window displays of the vast Galeries Lafayette or cross the cobbled courtyard.

Qatar is also using this system to reinforce food security, he says. “Using the same technology in farms, we have developed new methods to grow food in the summer with less energy consumption,” he says.

Of course, Qatar is heating faster than almost anywhere else on earth—the consequence of being surrounded by overheating seas. Climate experts believe the country will be largely uninhabitable within two decades.

What is more certain, however, is that the last eight years have been the hottest since records began in 1880. With heatwaves regularly scorching the MENA region, outdoor cooling is quickly becoming more important everywhere.

AIR-CON ON LIQUID NITROGEN

While sweltering in a café on Rome’s Piazza Navona in August 2019, Tal Leizer, founder of Practical Innovation, an Israeli startup incubator, decided to “seek a solution for sitting outdoors, in a world that is getting hotter every day.”

Three years later, her company Green Kinoko is readying production of Kenshō, an outdoor air conditioner that runs on liquid nitrogen. A canister is loaded into a compartment of the sleek free-standing cooler—it looks like a terrace heater designed by Apple—and the liquid is slowly released when switched on. It expands rapidly to nearly 700-times its volume as it becomes a gas. The cooler harnesses the energy in this expansion through a mechanical engine, blowing out nitrogen gas at a palatable -10°C (14 °F).

“We have received thousands of inquiries from about 80 countries,” says Leizer. “We’ve been contacted by potential investors, air-con manufacturers, distributors, and people who want the units for their homes.”

So far, 12 prototype units have been built, which were trialed in Tel Aviv cafés before the product was launched at the PLANETech World 2022 conference held in September. “We are now finalizing details for the initial production run, and we hope to be able to distribute the first coolers in the next few months,” says Leizer. “The first batch will be made in Israel, but we’re planning additional production capacity overseas when the mass rollout starts.”

Green Kinoko has also been approached by several companies interested in taking the technology in several different directions. “The technology could be applied to public transportation, urban architecture, open-air industrial plants, sports events, and many other areas,” says Leizer.

The unit, she says, is far more environmentally friendly than a regular air conditioner as it uses no mains power and doesn’t blow hot air out. Moreover, nitrogen makes up about 78% of the ambient air. Ideally, of course, the nitrogen would be distilled using green electricity.

“Our intention is eventually to make a product that will cost a similar amount to the existing solutions,” she says, adding that liquid nitrogen canisters would typically need to be replaced every ten days.