- | 9:00 am

Converse’s new crushed velvet sneakers are made from vintage dresses

Converse sourced more than 800 pounds of velvet to make the shoes.

In 1994, when velvet was all the rage, Converse created a red velvet version of its iconic Chuck Taylor sneaker. This year, just in time for the holidays, the sneaker brand launches another crushed velvet sneaker. And you’d never know by looking at them, but they’re made from old, discarded clothes.

[Photo: Converse]

[Photo: Converse]

Companies across the fashion industry are thinking about how to reduce this waste. Some designers, like Gabriel Hearst and Hillary Taymour, have created small collections from upcycled fabrics. And Levi’s makes some of its iconic 501 jeans from old jeans that have been chemically liquified and respun into new materials. But creating upcycled products at scale can be challenging, because it means collecting these old textiles and incorporating them into a new supply chain.

[Photo: Converse]

Brandon Avery, Converse’s head of innovation, says the brand’s sneakers are a good fit for upcycled fabrics. Historically, Converse’s iconic Chuck Taylor shoe has been made from cotton canvas, but it is possible to make it with different textiles. “It’s a very simple design, made from just a few pieces of fabric that are sewn together,” he says. “Over the years, we’ve made them from all kinds of materials, including denim and velvet.”

Over the past five years, Converse’s innovation team has been trying to figure out how to make sneakers from discarded clothes that already exist on the market. “The challenge is to design a shoe from these materials that will be popular with our customers, and that we can mass produce,” he says.

Converse partnered with Beyond Retro, which has expertise in collecting and sorting through old garments. Together, the two brands discussed what clothes are abundant in the vintage market. Velvet came up as a possibility because it is thick and durable, much like canvas, making it a good fit for a shoe upper.

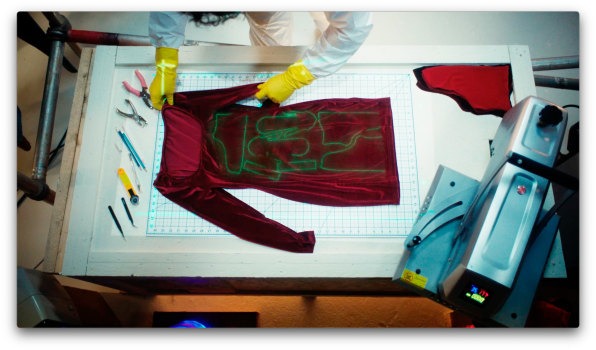

To make a large quantity of sneakers, Converse tasked Beyond Retro with collecting as much black and red velvet as possible. “There are many shades of red velvet out there,” says Jocelyn Briggs, Converse’s global director of product merchandising. “So, we gave them a spectrum of shades we would accept, to create consistency in the collection. But that said, the colors and textures of the velvet will vary from one pair to the next, so the customer is really getting a one-of-a-kind product.” (The sneakers range from a burgundy to a slightly brighter Christmasy red.)

Beyond Retro collected upwards of 500 pounds of fabric, which they then sanitized and then cut into large rectangles, based on Converse’s specifications. They then sent these rectangles to Converse’s factory in Vietnam, where they were cut into the specific shapes that make up a Chuck Taylor shoe upper, and then sewn together like any other sneaker before the rubber sole is added. “A big part of the process is working with our factory partners to train them in how to use these new materials,” says Avery.

The sneakers, which cost $95, launched this week, timed for the holidays. When I tried a pair, I found the material sturdy and resistant to scuffs. Avery hopes this means the shoes will last a long time, even after the velvet trend has come and gone.

For Converse’s designers, this experiment in up-cycling was an opportunity to explore what is possible as far as sustainability. Converse sells upwards of 100 million sneakers every year, and for Avery, the goal is to make more and more of these shoes from existing fabrics, rather than new materials. “We’re trying to bring the customer alongside us on this journey,” he says. “We think they’re ready to embrace the small variations in the material. Eventually, we think we can make sneakers with rips or paint splatters that show that the fabric has already lived another life.”