- | 10:00 am

Why this see-through factory was built in the middle of a forest

Designed by Bjarke Ingels Group, Vestre’s new furniture factory put a premium on transparency and sustainability.

Though the new Vestre furniture factory outside Oslo claims to be the world’s most sustainable factory, a more defendable title is that it’s the first to be influenced by Saturday morning cartoons.

The factory’s designer, architect Bjarke Ingels and his firm Bjarke Ingels Group, tapped into some childhood memories of Danish TV when devising the project’s design concept. As an interlude between cartoons, television stations would sometimes play brief films from inside factories, showing how everyday products like shoes and pencils were manufactured.“It was mesmerizing to watch these processes,” Ingels says by phone from Copenhagen. He decided to build that same sense of wonder directly into the factory itself.

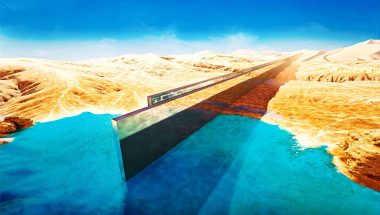

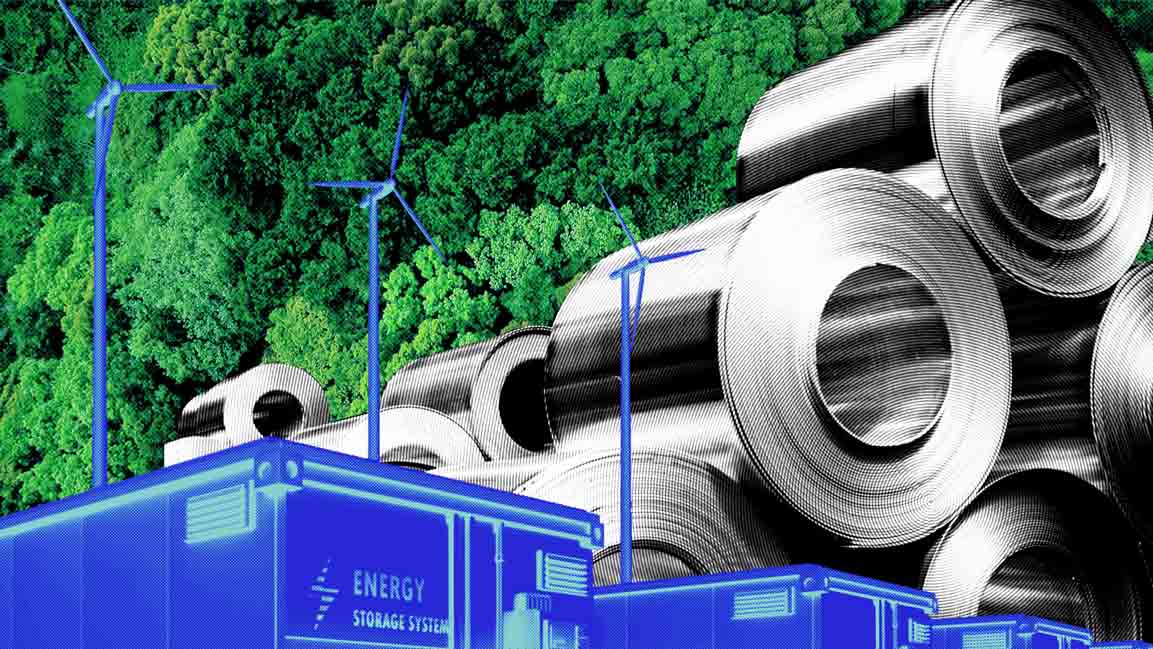

Vestre specializes in outdoor furniture for public spaces, like benches, planters, and garbage cans, and its early guidance to Ingels included a goal of transparency in the way it makes its products. The new factory, shaped like a plus sign, is where the company processes most of its wood, from sawing to painting to assembly. Outside sits a vast pine forest that the company has turned into a path-spliced public park.

Between the company’s main raw material outside and the processed wooden furniture inside are walls of clear glass, a literal nod to transparency. Like those Saturday morning television programs, the glass gives the curious public a way to peek behind the scenes. “You can press your nose flat against the windows and admire the marvel of 21st-century manufacturing,” says Ingels, whose firm is known for genre-blurring buildings like a power plant with a ski slope on top and dome structures 3D printed from moon dust.

A see-through factory—let alone one set amid 74 acres of publicly accessible forest—is a decidedly new take on the gruff and gritty factory of the past.“Normally, factories are these hostile, hermetic, no-trespassing, keep-out kinds of environments,” Ingels says. And with good reason: Companies have a natural concern for industrial espionage, as well as the workaday realities of needing to keep up production without a bunch of onlookers clogging the gears.

Vestre’s intention of pulling back the curtain could only go so far, and while most parts of the factory can be seen from the outside, the robotic arms and spinning saw blades in the work areas are just for employees. “Of course, it is still a factory,” Ingels says. “It’s a hardworking building.”

Inside, human furniture makers and automated industrial machines intermix in the four wings of the building, each dedicated to a certain task: milling, painting, assembly, and logistics. The factory uses a color-coded paint system on the floor to map out the functional flows of each quadrant and ease movement of materials between wings. The pathways, like directional aides in large hospitals, turn the floor into what Ingels calls a “rainbow of utility.” The designers even put the color system to work on the large-scale machines and robots, which required some special orders from industrial manufacturers.“It took some convincing,” Ingels says. “The first response from the German manufacturer was unmöglich, which means impossible.” The designers eventually got their way, and Vestre’s factory now includes a lime green room for painting and a bright red saw for cutting large boards. The scene inside is not unlike what a factory might have looked like in one of those old technicolor Saturday morning cartoons.

Though the transparency is the overarching theme, the title the company has given its factory, that of “the world’s most environmentally friendly furniture factory,” has some merit, too. The building was designed to have low carbon emissions, high on-site renewable energy production, and a small embodied footprint of greenhouse gas emissions to produce its building materials.The building was constructed primarily of wood, with columns, beams, and walls made of mass timber, insulation made of low-carbon wood chips, and a facade of insect-resistant charred wood. The concrete foundation was cut down to the minimum size possible to still hold up the building, and the designers negotiated with the local fire department to remove as few trees as possible between the building’s edge and the forest beyond.

“Every decision in the building has really been made with a clear focus on what is the smartest, simplest way to reduce the carbon footprint,” Ingels says.

Lining several of its outside walls, as well as the round central courtyard at the crosshatch of the plus sign, are triple-paned windows, which bring natural light into almost every part of the factory while keeping the temperature cool in summer and warm in winter.Large stairways line these windows both inside and outside, creating spaces for workers to move across floors and for visitors to peer in. At the top of the stairs is a rooftop deck looking out on the solar-paneled green roofs of the building’s four wings and the forest that spreads out beyond.

The building’s design gives the factory a kind of two-way transparency. Workers inside can look out and see trees while visitors can climb the building’s sloping stairs to see the furniture being made. As Ingels puts it: “Everything can function completely seamlessly, but everything can also be viewed and admired.”