- | 10:00 am

5 steps for removing ‘forever chemicals’ from your company’s supply chain

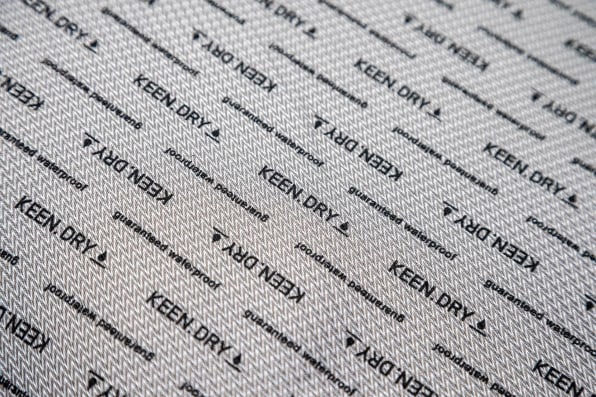

It took shoe company Keen four years and more than 10,000 hours to remove PFAS from its supply chain. Now, Keen is sharing how your company can do the same.

Keen was born in 2003 from a simple question: “Can a sandal protect your toes?” But this wasn’t our only goal. As a values-led, family-owned business, we also wanted to protect wild places and minimize our impact on them. I first joined in 2011 to be part of a business that’s doing good while making goods.

But while we were investing in partnerships with organizations including The Conservation Alliance and Leave No Trace, and repurposing waste to make shoes with fewer resources, we didn’t realize that some of our shoes were leaving a forever footprint of toxic chemicals known as PFAS—or per- and polyfluoroalkyl substances.

If you’re in the business of making things, there’s a good chance it involves at least one of these roughly 5,000 fluorinated compounds. In 2014, we discovered some of our shoes had PFAS, so we started working to remove them.

That journey was voluntary, but soon, some companies may be required to take it. Many states—including California, Colorado, Maine, New York, and Washington—have taken regulatory action on PFAS in apparel and cookware. In September 2022, California passed a law that prohibits the sale of most apparel or textile products containing PFAS in the state beginning in January 2025.

PFAS, commonly known as “forever chemicals,” never break down and remain in the environment long after the lifecycle of the product they were adhered to. CDC scientists have found PFAS in our blood, and they’ve been linked to cancer, immune system suppression, pregnancy-induced hypertension, developmental delays in children, and reduced fertility.

Yet because they can repel water, food, and stains, PFAS continue to be used in everything from women’s underwear and fast-food wrappers to cookware and outdoor gear. They’re used in so many consumer products, and are so long-lasting and persistent, that they now show up in places they absolutely shouldn’t, such as Arctic sea ice and breast milk.

We knew we didn’t want to be part of the problem. Now, we want to be part of the solution. It took us four years and over 10,000 hours to track down where PFAS were in our supply chain, eliminate them, find safer alternatives, and conduct third-party testing to ensure they haven’t come back. We’re happy to say that every Keen shoe made since 2018 is PFAS-free. We’re sharing what we learned so that other companies can follow suit—because PFAS in any supply chain affects all of us.

COMMIT TO A PFAS DETOX

Because these chemicals are so persistent, it takes persistence to get rid of them. We started by consulting with experts at the Green Science Policy Institute to understand more about these forever chemicals and their pervasiveness. Then we created a “Detox Initiative” to set goals and hold ourselves accountable. Committing to a PFAS detox requires a commitment across your value chain. It can become a rallying cry for your company around a shared purpose.

FIND OUT EXACTLY WHERE PFAS ARE IN YOUR SUPPLY CHAIN

Sounds pretty basic, right? We thought so, too. In footwear, PFAS are primarily found in durable water-repellent treatments on the outside of a shoe. But once we started digging into it, we found PFAS treatments added to hundreds of individual components, from shoelaces to packing receipts.

Task someone in your supply-chain organization to perform an audit of all materials and components sourced. Then, apply the precautionary principle of “using only what you need.” It’s an approach increasingly used in the fields of sustainable development, environmental protection, health, trade, and food safety.

Once you have the complete picture, you can plan your detox approach. At Keen, we eliminated 65% of our PFAS contamination simply by applying the precautionary principle. For example, we were treating water sandals with a PFAS-based water-repellent treatment. But why would we need to apply water repellency to sandals designed to get wet in rivers, lakes, and oceans? We didn’t, so we stopped.

IDENTIFY SAFE ALTERNATIVES

There’s a reason PFAS chemical compounds are used. They’re very good at repelling water and dirt, and they can create a nonstick coating on surfaces, including packaging. But perhaps they’re overengineered for most consumer goods? When there is a specific need for repelling moisture and resisting stains, choose alternatives that are safe for humans and the planet, effective in the repelling qualities needed, and affordable.

While these alternatives aren’t as easy to find as those made with PFAS, development and testing of safe options have grown significantly in recent years. There are effective options made from hydrocarbon resins and plant-based compounds. They do cost a bit more, but since we were able to apply the precautionary principle and completely eliminate the use of water repellency in a big chunk of our products, that helped us absorb the cost.

MAKE IT COMPANY POLICY

Having a chemical management policy and a Restricted Substances List (RSL) makes sure everyone, including your employees and suppliers, know the rules of the game when it comes to prohibited substances and chemicals in your supply chain and products. Require new and existing suppliers to send material samples to third-party laboratories to confirm they pass your standards prior to engaging in business. Our suppliers absorb this cost. We simply don’t do business with vendors who don’t comply with our standards.

With your updated chemical management policy and RSL in place, you’ll need to have the entire company—from your component and materials suppliers to your employees and partners—follow and enforce it. Post it on your website for everyone to see and add RSL compliance to your code of conduct to underscore its importance and set the rules for doing business with you.

ENFORCE COMPLIANCE WITH TESTING—AND KEEP ON TESTING

This is the forever work for keeping forever chemicals out. The good news is that testing of components (and the associated costs) can be the responsibility of, or the cost of doing business for, your supplier. Be sure that your supplier contracts have clauses that stipulate financial penalties for noncompliance, and that you apply these penalties if and when necessary. Trust, then verify.

You’ll want to have random finished products tested to ensure nothing was added during the assembly/manufacturing/shipping processes. (This is where we learned packing receipts were coated in PFAS to prevent ink smudge). These spot checks are your responsibility, so make sure to create a budget for third-party verified compliance. We invest about $75,000 annually for random testing, appropriate for a midsize company.

Not every company has a dedicated person or sustainability department that can take on this work. In fact, a lot of companies don’t even know what’s in their supply chain. Don’t let that be a deterrent. It could start with creating and sharing a PFAS report, setting up a task force, forwarding this article to management, or whatever makes sense for your organization.

Here’s the thing, until we all take action to remove PFAS from our shared supply chain, these toxic chemicals will continue to bioaccumulate in wildlife, and in us. So, please, take that first step, for humanity’s sake.