- | 10:00 am

Pharmaceutical scientists have figured out a new way to make moisturizer without the moisture

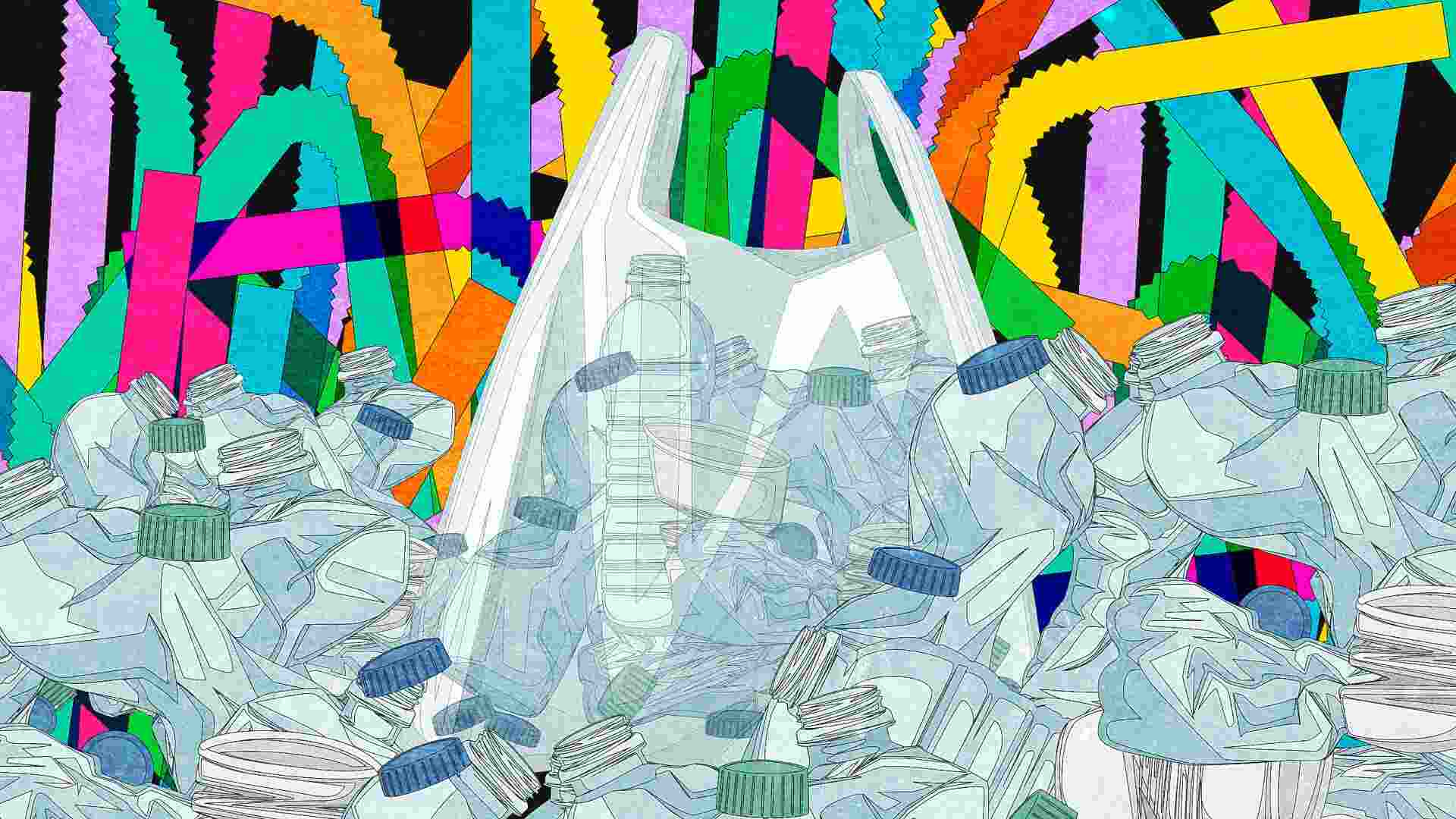

Paper-thin skincare products are easier to transport and more eco-friendly. Just add water.

Researchers at the University of East Anglia’s School of Pharmacy in the U.K. have developed technology that can remove nearly all water from a cosmetic product, allowing it to be packaged as thin, paper-like disks. Consumers can then add the water back themselves when they’re ready to use the product.

Most industrial processes that remove water from products use a lot of energy and heat, which can damage or deactivate a product’s active ingredients and can be costly to manufacturers, the lead researcher, Sheng Qi, told the website PackagingInsights. However, this new process can be performed at room temperature by spraying the product into thin, fast-drying sheets.

Waterless products like this can also help reduce emissions from packaging and shipping. According to a report by Our World in Data, 16.2% of all global emissions come from transportation of people and goods, and it’s one of the fastest-growing contributors to carbon emissions.

The less water that has to be transported with a product, the more densely the active ingredients in that product can be packaged. That ultimately means consumers can buy those products less frequently, in larger quantities, creating less packaging waste and emissions from shipping, not to mention cutting costs for the consumer.

Waterless products, such as powder, detergents, bar soaps, and shampoos, have been growing in popularity for years. The beauty industry has started to join in on the trend, with the waterless cosmetics market expected to grow to $14.7 billion in 2027, from $8.36 billion last year, according to a report by the Business Research Company. Even major industry players like L’Oréal are cashing in on the trend.

The new process is patent-pending and could be hitting shelves soon.