- | 8:00 am

3D printing with sound? Yep, that’s possible

A new technology instantly materializes objects using ultrasound holograms.

A machine that instantly materializes objects using ultrasonic holograms sounds like something found onboard the Starship Enterprise, but according to a recent breakthrough from scientists in Germany, it’s not science fiction—it’s reality.

A new study published this month in the journal Science Advances from the Max Planck Institute for Medical Research and Heidelberg University, explores the concept of “touchless 3D printing” and how it could be used, in particular, to print living tissue. While traditional 3D printing relies on techniques like adding layer after layer of matter, bonding them until you end up with an object; this new form of 3D printing uses sound waves that can push matter around without physically touching it. The achievement here is that these scientists found a way to build any 3D shape they want using those waves.

According to Kai Melde, the lead author of the study, there’s great potential to use this technology for the “assembly of biological cells” because “ultrasound is gentle and non-toxic to cells and the remote assembly without contact helps keep things sterile and the cells happy,” he explains.

The research asserts that conventional methods of printing living tissue are less than ideal because they are slow and apply mechanical or chemical stress on biological cells. “Several years ago we were wondering how we could assemble particles in a non-contact way and explored all kinds of fields,” he tells me. He and his team went through everything: optical, magnetic tweezers, electric, and, eventually, acoustic fields.

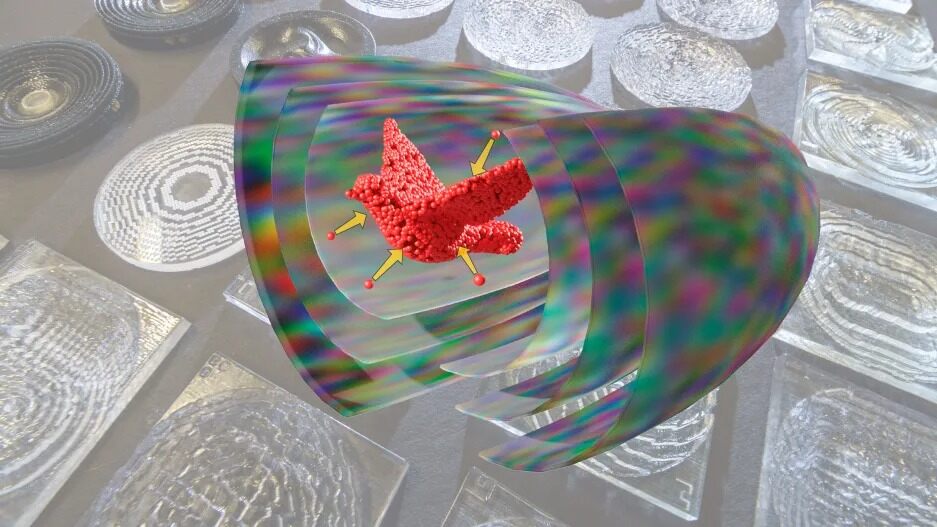

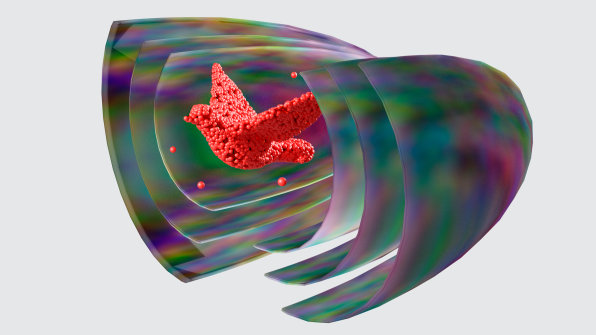

If you have ever been in a concert arena, you already know that sound affects physical matter: the blaring sound of the speakers exerts a force on your own body, sometimes so hard that it leaves you breathtless. In the lab, before Melde’s team started their work, ultrasonic acoustic fields were already manipulating tiny matter in simple ways, either organizing particles around a single point or in straight lines. The researchers’ eureka moment came when they thought about using holograms to shape the object in 3D space. But, instead of being made from light, the holograms were made of ultrasound. Think of the sound waves as invisible hands shaping matter without actually touching it; these sound holograms are effectively molds that could be made in any shape needed.

Melde explains that this was quite a complex achievement. Creating 3D shapes requires using multiple holographic fields that layer and interact with each other, according to Melde. The algorithms required to calculate the shapes of the holograms were so complicated that they required a lot of computing muscle: “One problem with the 3D computation is that the memory requirements quickly go up when you add the third dimension,” he says. “Then, on top you need to compute the wavefield for the whole volume, a process that needs to repeat again and again through the optimization process.”

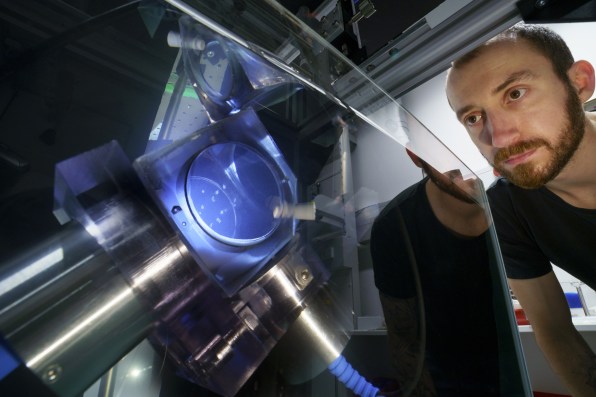

To solve this computational challenge, they turned to GPU acceleration—the processors used in gaming cards to render realistic complex 3D worlds—and Google’s TensorFlow, the most popular software for machine learning and artificial intelligence. According to Heiner Kremer, the team member who wrote all the required computing magic, “the digitization of an entire 3D object into ultrasound hologram fields is computationally very demanding and required us to come up with a new computation routine.”

Once the calculations are done, it’s time to “print” the object. This is a comparatively simple process. Their proprietary machine fires the ultrasound fields towards a lab dish, shaping the biological cells (or any microscopic matter, really) that’s been suspended in a liquid that feeds the cells nutrients to keep them alive. The amazing thing is that this is one single step: the object just forms instantly in one go, as opposed to traditional 3D printing processes, which take a very long time.

The maximum size of these experiments, Melde tells me, “was a double-turn helix with about 20 mm length and 10 mm diameter.” This may seem tiny, no bigger than one of your pinky’s phalanxes, but it’s quite extraordinary. It may be the first step towards a future in which we can safely bioprint organs, one of those dreams that once upon a time felt unachievable. But as sci-fi author Robert A. Heinlein once said, “everything is theoretically impossible, until it is done.”