- | 9:00 am

These toothbrush handles are custom designed for the 360 million people with dexterity issues

From arthritis to carpal tunnel, many people have conditions that make brushing a pain.

For people with dexterity and grip issues, the act of holding a thin toothbrush and carefully brushing their teeth can be a challenge, a pain, or an impossibility. Designers from the global brand consultancy Landor & Fitch see this as a design problem that results in the potential alienation of the estimated 360 million people worldwide with dexterity challenges.

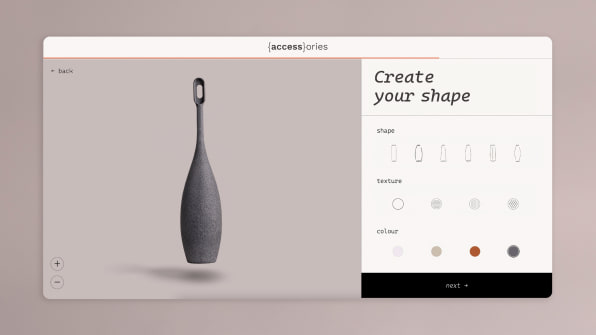

The company’s newest project aims to solve that problem. They’ve created an online platform called {access}ories, which uses a straightforward series of questions to develop customized, 3D-printed toothbrush handles for people. “It’s one size fits one,” says Luc Speisser, global chief innovation officer for Landor & Fitch.

Tailored to the grip, movement and pain points of individuals, the platform is an attempt to make toothbrushing easier for people with a variety of dexterity limitations, from carpal tunnel syndrome to persistent tremors to several types of arthritis. The resulting handles are like tiny sculptural vases in a range of shapes and colors, each capable of holding either a manual or electric toothbrush.

“We wanted to make it perfectly accessible, but also affordable and desirable,” says Speisser. “Very often when it comes to people living with disabilities, industries have come up with functional products with no regard to aesthetics. Why should it just be functional, and why couldn’t it be desirable?”

The idea for the project came out of an internal effort Landor & Fitch started in 2020 called the Good Squad, in which employees are allowed to spend up to 10% of their work time on projects focused on doing good in the world. Landor & Fitch art director Emily Price and a colleague came up with the concept of addressing the need for more accessible toothbrush design.

The toothbrush project kicked off in earnest about a year ago. The company brought in a large panel of people who experience dexterity challenges and learned directly from them about what doesn’t work in the typical toothbrush. Speisser says people shared how they’ve used rubber bands, tennis balls and other objects to hack conventional toothbrushes to work with their grip, and also how the act of brushing teeth can be so draining they need to rest for 30 minutes afterward. “That really informed the functional and the emotional needs,” Speisser says.

From this research, Landor & Fitch developed a design tool based on a brief set of questions to create the right size and grip for each user, including their dexterity condition or conditions, the diameter of their grip, whether they use a manual or electric toothbrush, and their preferred texture. To fine-tune the shape of the handle, the platform asks users to select their most easily graspable household object from a list that includes a soup can, a sauce bottle, a pear, and a tennis ball. “It’s so important for us to not use design language when we’re doing this, so that everyone can find the perfect shape for them,” says Price.

Speisser says several toothbrush manufacturers have reached out about the project. (He and Price had just gotten out of a meeting with a toothbrush company before our interview.) “One of them is really determined to make this work,” Speisser says.

For now, the project is just at a prototype stage, with about 10 handles 3D printed and shipped out. Speisser says the questions in the online design platform make 144 possible combinations of shape, grip, and color, and 3D printing is likely the best way of getting them produced. Customizing the handles to the needs of each user is also a way of getting these handles into users’ hands more quickly. “If you want to make the perfect product, it’s between two and five years. We just said, ‘we can’t wait,’” Speisser says. “We need to find a solution that works now.”